How To Open A Shipping Container

The baffling yet intriguing world of shipping containers, precisely their opening procedure, is a topic that tends to spark a myriad of questions. Defined by their structural simplicity yet nuanced locking mechanisms, there's no wonder one may encounter challenges for their first-time handling. In this enlightening discourse, we endeavor to shed light on precisely how to pry open a shipping container. To thoroughly grasp the complexity of the task, we'll delve into 'Understanding Shipping Containers and Their Locking Mechanism,' which demystifies the integral structure responsible for the securing of these enormous metal boxes. Following a deep dive into this concept, we'll transition to 'Tackling the Challenges in Opening a Shipping Container'. The section explores common hurdles encountered and effective ways of overcoming them. Finally, we'll conclude by providing a 'Step-by-Step Guide on How to Open a Shipping Container' to equip you with a practical approach to navigate this process successfully. So, allow us to ease your nerves and uncover the strategic art of unlocking a shipping container by first exploring the core of these colossal entities - their locking mechanism.

The baffling yet intriguing world of shipping containers, precisely their opening procedure, is a topic that tends to spark a myriad of questions. Defined by their structural simplicity yet nuanced locking mechanisms, there's no wonder one may encounter challenges for their first-time handling. In this enlightening discourse, we endeavor to shed light on precisely how to pry open a shipping container. To thoroughly grasp the complexity of the task, we'll delve into 'Understanding Shipping Containers and Their Locking Mechanism,' which demystifies the integral structure responsible for the securing of these enormous metal boxes. Following a deep dive into this concept, we'll transition to 'Tackling the Challenges in Opening a Shipping Container'. The section explores common hurdles encountered and effective ways of overcoming them. Finally, we'll conclude by providing a 'Step-by-Step Guide on How to Open a Shipping Container' to equip you with a practical approach to navigate this process successfully. So, allow us to ease your nerves and uncover the strategic art of unlocking a shipping container by first exploring the core of these colossal entities - their locking mechanism.Understanding Shipping Containers and Their Locking Mechanism

In the realm of global trade and transportation, shipping containers play a pivotal role. These seemingly nondescript steel boxes are exceptionally designed units that safeguard a vast array of goods while they journey across oceans. Our deep dive into understanding shipping containers will deconstruct three distinct, but interrelated aspects. Firstly, we will embark on an exploration of the evolution and design of shipping containers, tracing their history and distinctive architectural features. Moving further into the technical depth, we shall examine the composition of a shipping container’s locking mechanism, thereby shedding light on the critical aspects ensuring security during transit. Lastly, we will venture into the classification of shipping container locks, comparing their unique features and preferred applications. This layered analysis will not only consider the physical attributes of these worldly travelers but also the intricate lock systems that keep them sealed tight. So, let’s open the doors to the evolution and design of shipping containers, revealing the innovation and ingenuity that has revolutionized global commerce over generations.

The Evolution and Design of Shipping Containers

Shipping containers have undeniably revolutionized freight transport since their inception. The evolution of shipping containers has been marked by a progression in design that has made these instrumental elements in global trade more efficient, resilient, and adaptive to diverse needs. What began as a basic steel structure in the mid-20th century evolved into a product of meticulous design and engineering, balancing weight, durability, and ease of use. Early designs of shipping containers were different from the standard, uniform models we often see today. They were smaller, less durable and had no uniform size or shape. As maritime transport grew in popularity, a need for standardization arose to streamline transport and improve efficiency. This demand inspired the shipping industry to evolve and innovate, resulting in the International Organization for Standardization (ISO) standards we use today. These standards mandate the exact dimensions, quality, durability, and certain design features of shipping containers. This uniformity allows different shipping containers to be stacked, transported, and handled easily across different modes of transport globally. Arguably, one of the most critical design elements of shipping containers is their locking mechanism. This feature ensures the safety and security of the goods inside, preventing theft or tampering during transit. The twist lock system - a standout innovation in shipping container evolution, is one such locking mechanism. Solid and dependable, it works by using rotating cones that secure together when turned, creating a robust coupling that can withstand heavy loads. However, the evolution and design of shipping containers don't stop at the physical structure. The advent of technology has introduced 'smart containers,' boasting features such as real-time tracking and temperature control. Such advancements provide unprecedented transparency into cargo transit, enhancing overall trade efficiency. The design of shipping containers has therefore been an exciting journey, reflecting the changing needs and demands of global trade. As we delve deeper into understanding their locking mechanisms, we appreciate the intricate blend of engineering, innovation, and necessity that have shaped these humble steel boxes into crucial cogs in the wheel of international commerce. There's a lot more to opening a shipping container than meets the eye, and it’s this intricate ballet of design and utility that makes it truly fascinating.

Components of A Shipping Container Locking Mechanism

Shipping container security is paramount in the transport industry as the locking mechanism plays a vital role in safeguarding valuable items during shipments. The locking mechanism of a shipping container can have two main elements: the manual lock and the cam keeper, both of which work together to ensure robust security. The manual lock, often built of hardened steel, is the key component that offers a physical barrier against threats. Acting as the first line of defence, the lock resides on the container door handle and has a unique key system that allows only authorized users to access the contents. Ensuring the lock's durability and resistance against weather changes or intrusions are paramount factors when considering the manual lock's quality. The second part is the cam keeper - an intricate part of the locking mechanism that secures the container doors together when locked. The cam and keeper are both housed within the door handle and are pushed together when the handle is turned. They interlock, creating a protective barrier that cannot be opened without unlocking the manual lock first. Both components work together to form a high-security locking system that is not easily tampered with. It is important to maintain and check the functionality of both elements regularly to ensure the container remains secure throughout its use. Moreover, shipping containers might also incorporate additional digital security features, such as smart locks with GPS tracking, biometric access, or remote controls. These locking mechanisms are designed with advanced technology to provide real-time tracking and unauthorized access alerts, ensuring a higher level of security for valuable cargo. Understanding shipping containers' locking mechanisms' components fundamentally helps users in managing access to the containers more securely and safely. It serves as a critical aspect in the world of shipping, influencing not only security but also effectiveness and efficiency in the global cargo transportation sector.

Common Types of Shipping Container Locks

Shipping containers come equipped with security measures that help to protect the valuable goods they hold. One critical piece of security is the lock. There are several types of shipping container locks that provide varying degrees of safety. Firstly, there are padlocks. These are highly versatile being able to secure both the doors and the lockbox - a steel box that houses and protects the lock. Padlocks are available in several models including key and combination setups, featuring unique keys for increased security. They also come with anti-drill and anti-pick designs to deter potential thieves. Next are crossbar locks. While not as commonplace as padlocks, they offer a significant upgrade in security. Fitting over the rods on the container door, they deter forcible entries by inhibiting door movement, even in the event of the lock being sawn off. An even higher level of security is offered by cargo door locks. These industrial-grade locks fit onto the handle and locking system of the door, clamping them together. They require an excessive amount of force to remove, acting as a strong deterrent to thieves. Finally, there are bolt seals - one-time use, tamper-proof devices. They’re made of metal and harder to break than standard locks. Once they’re installed, they can only be removed by breaking them, revealing any illicit attempts to gain access to the container. Concluding, container locks are a vital aspect of any shipping container. Their different types address the varied security needs dictated by the kind of cargo transported, the expected length of transit, and potential threat scenarios. Understanding which type of lock is most fitting for your needs dramatically enhances the safety offered by your shipping container. A thorough knowledge of the role and functionality of these locking mechanisms ensures that you can confidently and securely transport your goods, safeguarding your valuable assets.

Tackling the Challenges in Opening a Shipping Container

Opening a shipping container may seem like a straightforward task, yet it can be riddled with unexpected challenges that require strategic problem-solving. From confronting rust and corrosion to wrestling with stuck or broken container locks and maneuvering stacked containers safely, it's clear that tackling these potential issues head-on is crucial for a seamless operation. Understanding the potential obstacles is the first step in constructing a practical, efficient approach to their resolution. Rust and corrosion, for example, are often underestimated foes. Prolonged exposure to moisture and air, particularly in salty environments, can weaken the structural integrity of the container, making it susceptible to rusting. This deterioration can make opening a container a Herculean task that jeopardizes both time and safety. This issue, along with the struggle of dealing with malfunctioning container locks and the intricacies of handling stacked containers, is what we will delve into in this article. Adopting a proactive approach to these challenges will move you closer to mastering the art of shipping container management, starting with a detailed exploration of mitigating rust and corrosion.

Dealing with Rust and Corrosion

Dealing with rust and corrosion is a critical aspect of opening a shipping container. Rust, formed by the oxidation of iron in the presence of water and oxygen, can be a pervasive problem for shipping containers, and corrosion can significantly weaken a container's structural integrity. However, effective strategies can help with these issues and extend the lifespan of your shipping container. Rust typically begins from tiny scratches or dents on the container's surface, which become entry points for moisture and oxygen. Over time, these conditions set the stage for the formation of rust. Left untreated, rust can spread across the metal surface, eventually causing significant damage and making it challenging to open the container. Corrosion, on the other hand, is an electrochemical reaction that occurs when metal comes in contact with water, leading to the deterioration of the metal surface. Corrosion can transform a robust shipping container into a frail shell, leading to serious concerns about the safety and the integrity of the items stored inside. To effectively tackle this problem, a systematic and preventative approach is necessary. Regular maintenance checks are crucial in identifying the early signs of rust and corrosion. Once spotted, localized cleaning, followed by the application of a rust converter, can halt the spread of rust. A rust converter is a treatment that turns rust into a protective, paintable surface, thereby stopping further rusting. For widespread rust, professional services might be necessary as they have more advanced solutions and equipment. They can sandblast the affected areas before applying a rust-inhibitor and a fresh coat of paint, thus restoring the container to its original state. Corrosion prevention methods are also essential. Techniques like hot-dip galvanizing, which applies a zinc coating to the metal, and cathodic protection that utilises an opposite electric charge to counteract the corrosion process, can be particularly effective. In the battle against rust and corrosion, understanding the causes and prevention methods is just half the battle. Strategic application of these prevention methods is the key to maintain the reliability and durability of your shipping container. Through regular maintenance and by adopting proactive measures, one can effectively tackle these challenges in opening a shipping container.

Overcoming Stuck or Broken Container Locks

Dealing with stuck or broken container locks can be one of the most persistently troubling issues in the process of opening a shipping container. This problem, while seemingly innocuous, can turn out to be a stormy sea for those who're not prepared. It's easy to underestimate the difficulty it poses, but the reality is that locks are the backbone of security for shipping containers, and when they malfunction, it can be a real headache. One of the primary causes of locks getting stuck or broken is exposure to harsh environmental conditions. Rain, snow, or even the salty sea air can rust the locks over time, making them hard to open. Sometimes, an ineffective locking device or structural damage can contribute to the problem. Nonetheless, it's not an insurmountable challenge. Overcoming an unyielding lock requires patience, skill, and the right tools. Forceful attempts can worsen the situation, potentially causing irreversible damage. Instead, one should opt for a systematic approach. A silicon or graphite-based lubricant can soften the rust and make the lock turn easier. Spraying this and leaving it to soak in for a few minutes often does the trick. Sometimes, the issue isn't rust, but a physical barrier inside the locking mechanism itself. In such situations, the use of locksmith pick sets or decoder tools can help. These tools allow you to manipulate the internal components of the lock carefully, potentially dislodging any blockages. If DIY methods fail, calling in professional locksmiths or a container lock specialist is the best plan of action. They come equipped with the right training, skills, and advanced tools necessary to handle these situations with ease. Overcoming stuck or broken container locks ultimately relies on understanding the problem, patiently employing the right techniques, and knowing when to call in professionals. This problem-solving aspect is part and parcel of tackling the challenges in opening a shipping container. Although daunting at first glance, with the right approach, this challenge can be effectively addressed, ensuring the smooth operation of your shipping activities. Remember, it's always advisable to prevent rather than deal with such issues. Regular maintenance, using high-quality locks, and protecting your containers from harsh environmental conditions can significantly reduce the likelihood of a lock getting stuck or broken. After all, as the old adage goes, "prevention is better than cure."

Handling Stacked Containers Safely

Handling stacked containers safely is a critical chapter in tackling the challenges of opening a shipping container. A sort of high-stakes Jenga, dealing with stacked shipping containers demands comprehension of certain principles and meticulous implementation of specific guidelines. Firstly, it's essential to understand that stacked containers pose a unique danger due to their extreme weight. One 20 feet shipping container, when empty, can weigh approximately 2.3 tons, making potential accidents severe and potentially fatal. Additionally, their weight amplifies with height; a significant safety concern that workers need to use a mix of technical knowledge and common-sense safety measures to mitigate. Moreover, in managing stacked containers, balance and stability are paramount. As these containers are usually stacked high, even a minor shift may result in a cascading effect, toppling other containers in the process. Therefore, workers need to ensure the stacks are level and secure, with no visible signs of leaning or instability. In connection with safety protocols, workers should always use proper lifting equipment when handling the containers. Forklifts, cranes, or straddle carriers, specifically designed for maneuvering heavy loads, should be enlisted for this task. Team members should be adequately trained and adhere to strict safety standards during operation. Furthermore, workers need to ensure that containers are properly locked or sealed when in stacks. This prevents the accidental opening of doors, which could result in undesired shifts in weight. All locking mechanisms, latches, and hinges should be thoroughly inspected and maintained regularly. Finally, environmental conditions should be considered in efforts to handle stacked containers safely. In adverse weather, like high winds or heavy rains, it's prudent to postpone work. Wind can significantly add to the instability of stacked containers while rain can make surfaces slippery, leading to accidents. In conclusion, the safe handling of stacked containers is a multifaceted undertaking requiring expertise, vigilance, and due diligence. It should not just be seen as part of the process of tackling challenges in opening a shipping container, but rather as a pivotal step towards fostering a safe and effective work environment. Remember, safety shouldn't be a policy, it should be a principle.

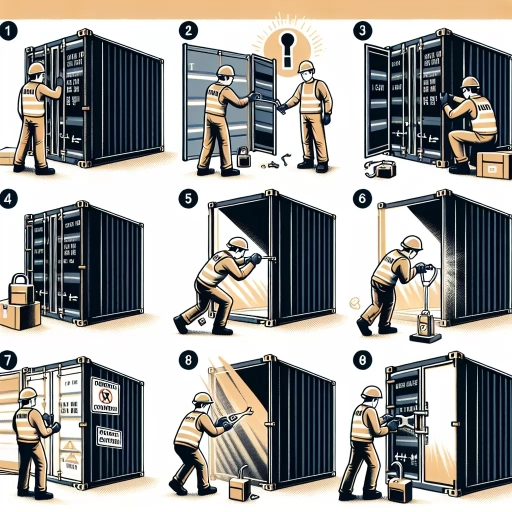

Step-by-Step Guide on How to Open a Shipping Container

In this all-encompassing guide, we will walk you step-by-step through the correct and efficient process of opening a shipping container. It's a straightforward task, but it requires a trick or two, especially if it's rusted or jammed. To make it a smooth operation, three critical elements must be considered - preparation and safety precautions, the necessary tools, and the actual process of opening the door. The first step, preparation and safety precautions, cannot be overlooked as it ensures you are guarded against potential accidents. This phase is your shield, protecting you from unforeseen eventualities. Next, having the right tools at your disposal significantly reduces the risk of damaging the container or injuring yourself. After all, using the correct gear could be the difference between a ten-minute job and a two-hour struggle. Finally, we dive into the actual processes involved in opening a shipping container door. This section reduces the task into manageable, easy-to-follow steps. Stay with us as we delve into the first stage, which is preparing oneself and taking safety precautions before you even touch that container.

Preparation and Safety Precautions Before Opening

Preparation and Safety Precactions Before Opening

Before delving into the process of opening a shipping container, it's important to stress that preparation and stringent safety precautions are the keys to successfully unlock the metallic giant without jeopardizing one's safety. You are not just wielding a standard door here, but dealing with a hefty structure, often crammed with goods, and potentially perilous if not handled correctly. A thorough inspection should be the starting point of your pre-opening procedure. Look for any visible external damage or any unusual elements in the container structure that may pose risks during the opening process, such as sharp protrusions or rusted areas. Ensure that the container is on an even and stable surface to avoid any precarious tilt or movement. Lighting conditions around the container should be adequate, as improper lighting can lead to mishaps. PPE (Personal Protective Equipment) is absolutely essential in this process. Workers should be equipped with helmets, gloves, safety shoes and high visibility clothing. These simple yet effective tools can make a substantial difference in the level of safety during the process. Care should also be taken to have the right tools for the job. Using the wrong tools can lead to unnecessary difficulty in opening the doors, cause damage to the container, or even result in personal injury. Basic tools, such as padlock clippers, a ratchet strap, and a pry bar, are recommended. It is crucial to be aware of what is inside the container. Some containers might contain hazardous materials or chemicals, and others might be under pressure due to temperature or altitudinal changes during travel. Hence, always approach with calculated caution. Lastly, ensuring proper training on how to handle and work with shipping containers is a crucial element of preparation. Workers involved in the process should be well-aware of the potential risks and understand the protocol for any unforeseen situations. Taking the time to prepare adequately and safeguard against possible accidents can ensure that the process of opening a shipping container goes as smoothly and safely as possible. Every intricate detail underlined in this paragraph acutely supports the sequential, meticulous process detailed in the main content: "Step-by-Step Guide on How to Open a Shipping Container."Tools Needed to Open a Shipping Container

Opening a shipping container can be a somewhat intricate process requiring the use of specific tools. These tools are instrumental in ensuring the container is opened safely and efficiently. The importance of having the correct tools for this job cannot be overstated; using the wrong tools can lead to damage to the container and its contents, or even personal injury. The first tool needed is a high-quality bolt cutter. Bolt cutters are incredibly practical and versatile, able to cut through various types of metal. In the case of shipping containers, they prove instrumental in removing any bolts or heavy-duty seals that are securing the container doors. Secondly, a reliable lock pick set is essential if the shipping container is locked and the key is lost or unavailable. This tool gives you the ability to unlock the container without having to cause any physical damage to it. Remember, picking a lock requires a certain level of skill and practice to be performed successfully. Investing in a good quality crowbar is also advisable. Crowbars provide the leverage needed to pry open the doors of the shipping container, especially if they have been sealed shut due to rust or other damages. Be sure to use crowbars with comfortable grips to prevent hand strain during this potentially strenuous task. Gloves are another crucial tool, offering protection for your hands against sharp edges and heavy objects while opening the container. Shipping containers often contain metal components that can cause scrapes, cuts, or other injuries. Using thick gloves ensures your safety during the process. Lastly, lubrication spray can be effectively used to lessen friction in the hinges of the container doors, making them easier to open. This makes a significant difference, particularly in older, rusted containers. In conclusion, preparing these tools before opening a shipping container is a must to prevent potential damages, injuries, and delays. Ensuring a smooth and efficient process requires the correct tools, knowledge, and techniques.

Processes in Opening a Shipping Container Door

If there's one thing that can seem surprisingly challenging the first time around, it's the process of opening a shipping container door. It requires an informed, step-by-step method to ensure a smooth and successful action. The procedure for opening the heavy, often unwieldy doors is not as simple as turning a knob, but with knowledge and the right techniques, it becomes much easier. To decipher the seemingly complex mechanisms involved, understanding the anatomy of the container door is incredibly essential. The key components include the locking handles, handle hub, cam, cam keeper, and the door gasket. Mastery over these components helps in carrying out the procedure effectively without straining muscles or risking injury. The first step in the process starts with drug handling. Before attempting to open a shipping container door, one must enure that the container is free from drugs that could hamper the process - it's imperative to a trouble-free opening. The locking handles are an integral part, and hold the secret to a successful unlocking process. Push up the handle to disengage the bars from their position. It's worth mentioning again that patience and a bit of strength may play a big part in this step, given how the handle might be heavy and slightly rusty if the container is old. Following this, the handle hub is the focal point of your attention. In turning the handle hub towards the right, you allow the cams at the bottom and top of the door to disengage from the cam keepers. This effectively loosens the door, providing the nudge you need to access the interior of the container. At this point, the door becomes somewhat independently functional, but it's not the end of the process. Swing the door open but remember to hold on tight because the weight of the door could be surprising. Lastly, inspecting the door gasket- the rubber seal lining the edge of the door - is important to ensure it's in good condition and can protect the contents of the container from the harsh elements of the environment. Though the process might appear cumbersome, especially to the uninitiated, adepts in the field would affirm the relative ease of their task with time and familiarity. As a shipping container door opening novice, practice and patience go a long way. Rest assured, as complex as this mechanism seems, it is designed for utmost efficiency and supreme protection of goods during transit.