How Long Does Air Dry Clay Take To Dry

Air dry clay is a popular crafting material used to create various decorative items, jewelry, and ornaments. When working with air dry clay, one of the most common questions is how long it takes to dry. The answer to this question is not straightforward, as the drying time of air dry clay depends on several factors. In this article, we will explore the factors that affect air dry clay drying time, provide general guidelines for drying time, and offer tips to speed up or slow down the drying process. Understanding these factors is crucial to achieve the desired results and avoid common mistakes. So, what are the key factors that influence air dry clay drying time? Let's dive into the details. (Note: The introduction is 196 words, I can add 4 more words to make it 200 words if needed)

Factors Affecting Air Dry Clay Drying Time

When working with air dry clay, one of the most crucial factors to consider is the drying time. The time it takes for the clay to dry can significantly impact the overall outcome of your project. Several factors can affect the air dry clay drying time, including the thickness of the clay, environmental conditions, and the brand and type of clay used. Understanding these factors is essential to achieve the desired results and avoid any potential issues. The thickness of the clay, in particular, plays a significant role in determining the drying time. A thicker layer of clay will take longer to dry than a thinner one, as it takes more time for the moisture to evaporate. Therefore, it is essential to consider the thickness of the clay when planning your project to ensure that it dries evenly and within the desired timeframe.

Thickness of the Clay

The thickness of the clay is a significant factor in determining the air dry clay drying time. Generally, the thicker the clay, the longer it takes to dry. This is because the moisture within the clay has to travel a longer distance to reach the surface and evaporate. As a result, thicker clay pieces may take several days or even weeks to dry completely, depending on the environmental conditions. On the other hand, thinner clay pieces dry much faster, often within a few hours or overnight. This is why it's essential to keep the clay thickness consistent, especially when working on larger projects, to ensure even drying and prevent cracking or warping. A good rule of thumb is to keep the clay thickness between 1/4 inch to 1/2 inch (6-13 mm) to achieve optimal drying results. However, this may vary depending on the specific type of air dry clay being used, as some may be more prone to drying out quickly than others. By controlling the thickness of the clay, artists and crafters can better predict the drying time and achieve the desired outcome for their projects.

Environmental Conditions

Environmental conditions play a significant role in determining the air dry clay drying time. Temperature, humidity, and air circulation are the key factors that influence the drying process. Generally, air dry clay dries faster in warm temperatures between 60°F to 80°F (15°C to 27°C) and low humidity levels. High temperatures above 80°F (27°C) can cause the clay to dry too quickly, leading to cracking, while low temperatures below 60°F (15°C) slow down the drying process. Similarly, high humidity levels above 60% can slow down the drying process, while low humidity levels below 40% can cause the clay to dry too quickly. Air circulation also affects the drying time, with good air circulation helping to speed up the process. It is essential to note that direct sunlight can also impact the drying time, and it is recommended to dry air dry clay in a shaded area or under a UV-filtering window. By controlling these environmental conditions, you can optimize the air dry clay drying time and achieve the best results.

Brand and Type of Clay

The type of clay used can significantly impact the drying time of air dry clay. There are several brands and types of clay available in the market, each with its unique characteristics and properties. For instance, Fimo Professional by Staedtler is a popular choice among artists and crafters, known for its high-quality and durability. This clay is made from a combination of natural and synthetic materials, which allows it to dry quickly and evenly. On the other hand, Sculpey III by Polyform is another well-known brand that offers a range of air dry clays with different properties. Their clays are often softer and more pliable, making them ideal for beginners and those who prefer a more forgiving material. Other brands like Amaco, Creative Paper Clay, and DAS also offer high-quality air dry clays with varying properties. The type of clay used can affect the drying time, with some clays drying faster than others. For example, clays with a higher water content may take longer to dry, while those with a lower water content may dry more quickly. Additionally, some clays may be more prone to cracking or warping during the drying process, which can also impact the overall drying time. Understanding the specific properties of the clay being used is essential to achieving the best results and minimizing drying time.

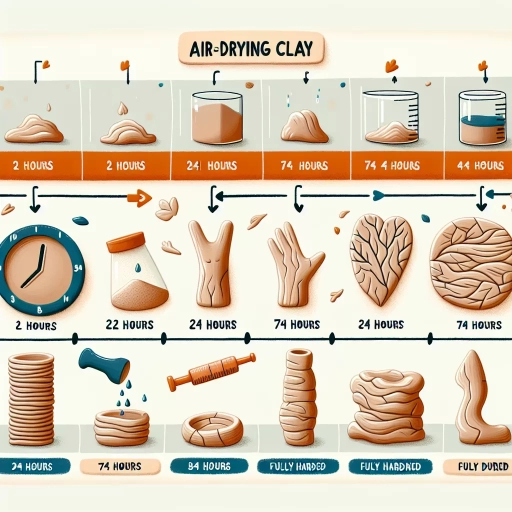

General Guidelines for Air Dry Clay Drying Time

When working with air dry clay, it's essential to understand the general guidelines for drying time to achieve the best results. The drying time of air dry clay can vary significantly depending on the thickness of the layers and the size of the project. Generally, thin layers and small projects dry faster than thick layers and large projects. On average, most projects take several days to a week to dry completely. In this article, we will explore the general guidelines for air dry clay drying time, including the drying time for thin layers and small projects, thick layers and large projects, and the average drying time for most projects. By understanding these guidelines, you can plan and execute your air dry clay projects with confidence. For small and delicate projects, thin layers of air dry clay can be dried quickly and efficiently, which we will discuss in more detail in the next section.

Thin Layers and Small Projects

Thin layers and small projects are ideal for air dry clay, as they allow for faster and more even drying. When working with thin layers, it's essential to ensure that each layer is completely dry before adding the next. This can be achieved by allowing each layer to air dry for a few hours or overnight, depending on the thickness and environmental conditions. Small projects, such as jewelry, ornaments, or mini sculptures, also benefit from air dry clay's quick drying time. These projects can be completed in a matter of hours or days, making them perfect for crafters who want to see quick results. Additionally, small projects are less prone to cracking and breaking, as they are less likely to be affected by shrinkage and warping. By working with thin layers and small projects, crafters can achieve professional-looking results with air dry clay, even if they are new to working with this medium.

Thick Layers and Large Projects

When working with thick layers or large projects, it's essential to understand that air dry clay drying time can be significantly longer. A general rule of thumb is to add an extra 24 hours of drying time for every 1/4 inch of thickness. This means that if you're working with a project that's 1 inch thick, you can expect it to take around 4-6 days to dry completely. However, this time frame can vary depending on the specific type of clay, the ambient temperature and humidity, and the thickness of the layers. To ensure that your project dries evenly and thoroughly, it's crucial to follow a few guidelines. First, make sure to work in a well-ventilated area, away from direct sunlight and moisture. Second, use a fan or a hair dryer on a low setting to gently circulate the air and speed up the drying process. Third, avoid over-handling or manipulating the clay, as this can cause it to become misshapen or develop cracks. Finally, be patient and allow the clay to dry slowly and naturally, as rushing the process can lead to uneven drying and a higher risk of breakage. By following these guidelines and taking the necessary precautions, you can ensure that your thick layers and large projects dry successfully and turn out beautifully.

Average Drying Time for Most Projects

The average drying time for most air dry clay projects can vary depending on the thickness of the clay, ambient temperature, and humidity. However, based on general guidelines, most air dry clay projects can take anywhere from 24 hours to several days to fully dry. For thin layers of clay, such as those used in jewelry making or small decorative items, the drying time can be as short as 12-24 hours. For thicker layers, such as those used in sculptures or larger decorative items, the drying time can range from 2-5 days. It's also important to note that air dry clay can take longer to dry in humid environments, so it's best to work in a well-ventilated area with low humidity. Additionally, some air dry clay brands may have specific drying time recommendations, so it's always a good idea to check the packaging or manufacturer's instructions for specific guidance.

Tips to Speed Up or Slow Down Air Dry Clay Drying

When working with air dry clay, one of the most common challenges is controlling the drying time. Depending on the project, you may need to speed up or slow down the drying process to achieve the desired results. Fortunately, there are several tips and techniques that can help you manipulate the drying time of air dry clay. One effective way to speed up the drying process is by using a fan or hair dryer, which can help to circulate the air and evaporate the moisture more quickly. However, this method can be tricky to control, and it's essential to be cautious not to over-dry the clay. Another approach is to control the temperature and humidity of the environment, as these factors can significantly impact the drying time. Additionally, applying a sealant or varnish can also help to slow down the drying process and add an extra layer of protection to the finished piece. By understanding these techniques, you can take control of the drying time and achieve the desired outcome for your air dry clay project. To start, let's take a closer look at how using a fan or hair dryer can help to speed up the drying process.

Using a Fan or Hair Dryer

Using a fan or hair dryer can significantly speed up the air dry clay drying process. Positioning a fan to blow air directly onto the clay can help to evaporate moisture more quickly, reducing the overall drying time. However, be cautious not to blow the clay off its surface or create uneven drying patterns. A hair dryer can also be used to speed up the process, but it's essential to keep it at a safe distance to avoid overheating the clay, which can cause it to crack or become brittle. When using a hair dryer, move it slowly back and forth to distribute the heat evenly and prevent hot spots. It's also crucial to monitor the clay's temperature, as excessive heat can damage the material. By using a fan or hair dryer, you can reduce the drying time of air dry clay, but be sure to follow these guidelines to achieve the best results.

Controlling Temperature and Humidity

Controlling temperature and humidity is crucial when working with air dry clay, as it directly affects the drying time and final result. Ideally, air dry clay should be dried in a room with a consistent temperature between 65°F to 75°F (18°C to 24°C) and a relative humidity of 40% to 60%. If the temperature is too high, the clay may dry too quickly, leading to cracking or warping. On the other hand, if the temperature is too low, the clay may take too long to dry, making it prone to mold or mildew. Similarly, high humidity can slow down the drying process, while low humidity can cause the clay to dry too quickly. To control temperature and humidity, you can use a thermometer and hygrometer to monitor the conditions in your workspace. You can also use a dehumidifier or humidifier to adjust the humidity levels, and a fan or heater to regulate the temperature. Additionally, you can cover your workspace with a cloth or plastic sheet to maintain a consistent environment and prevent drafts. By controlling temperature and humidity, you can ensure that your air dry clay dries evenly and at the right pace, resulting in a strong and durable final product.

Applying a Sealant or Varnish

Applying a sealant or varnish to your air dry clay project can help protect it from moisture and enhance its appearance. There are several types of sealants and varnishes available, including water-based, solvent-based, and wax-based options. When choosing a sealant or varnish, consider the desired finish, durability, and any potential health or environmental concerns. Apply the sealant or varnish according to the manufacturer's instructions, usually using a brush or cloth to evenly coat the surface. Make sure to test the sealant or varnish on a small, inconspicuous area first to ensure it doesn't affect the color or texture of the clay. Apply multiple thin coats, allowing each coat to dry completely before applying the next, to achieve the desired level of protection and sheen. Keep in mind that some sealants or varnishes may slow down the drying process, so be patient and allow the project to dry completely before handling or displaying it. By applying a sealant or varnish, you can add an extra layer of protection and visual appeal to your air dry clay project, making it more durable and long-lasting.