How To Cut Baseboard Angles

Home improvements, Do-It-Yourself (DIY) projects, and woodworking crafts often share a common hurdle - cutting baseboard angles accurately. Adding well-fitted baseboards to your space can enhance the overall aesthetics, but accomplishing those perfect cuts can be a challenge without a solid foundational knowledge. This comprehensive article is designed to navigate you through the meticulous process of cutting baseboard angles in three practical stages. First, we'll demystify the basics, shedding light on understanding the rudimentary principles behind cutting baseboard angles. Next, we dig into the preparations necessary before making the cut - because a good preparation paves the way for flawless execution. Finally, we delve right into the nitty-gritty of the cutting process itself, arming you with tips and tricks to slice through those angles with the utmost precision. This methodical approach ensures you have a thorough understanding, always prepared before the task and skillful during the action. Let's dive right into understanding the real groundwork - the basics of cutting baseboard angles.

Home improvements, Do-It-Yourself (DIY) projects, and woodworking crafts often share a common hurdle - cutting baseboard angles accurately. Adding well-fitted baseboards to your space can enhance the overall aesthetics, but accomplishing those perfect cuts can be a challenge without a solid foundational knowledge. This comprehensive article is designed to navigate you through the meticulous process of cutting baseboard angles in three practical stages. First, we'll demystify the basics, shedding light on understanding the rudimentary principles behind cutting baseboard angles. Next, we dig into the preparations necessary before making the cut - because a good preparation paves the way for flawless execution. Finally, we delve right into the nitty-gritty of the cutting process itself, arming you with tips and tricks to slice through those angles with the utmost precision. This methodical approach ensures you have a thorough understanding, always prepared before the task and skillful during the action. Let's dive right into understanding the real groundwork - the basics of cutting baseboard angles.Understanding the Basics of Cutting Baseboard Angles

Understanding the basics of cutting baseboard angles is vital in achieving seamless and professional-looking corners in any room. This process involves three fundamental steps: measuring the angle, identifying the type of angle, and choosing the right tools. Acquiring the knowledge on these aspects would vastly improve the aesthetic of your baseboard installation project and help to avoid the common pitfalls of miscalculations and improper cuts. Starting with measuring the angle accurately, it is important to understand that baseboard angles are not always a standard 90 degrees. Factors like the nature of the building's construction and settling over time may lead to slight variations. Measuring the angle allows for precise cuts and contributes to a cleaner final look. The subsequent step involves identifying the type of angle, which could be obtuse, acute, or a right angle, as this makes the difference in determining your cutting approach. Finally, selecting appropriate tools further ensures a precision cut, whether it be a miter saw or a coping saw. We begin with the vital first step: Measuring the angle.

1.1 Measuring the Angle

Knowledge of measuring angles accurately is foundational when cutting baseboard trim, a construction task that's essential for achieving a professional finish when installing floor trim, wainscoting, or even crown molding. Remember, any room's corner isn't necessarily a perfect 90-degree angle. Variations in walls and floors because of settling or imperfect construction may mean that even seemingly straightforward inside and outside corners are not quite 90 degrees. Because of these discrepancies, the ability to correctly measure and transfer these angles to your baseboard becomes critical. Begin the process by using a protractor or an adjustable bevel gauge. A protractor is a semi-circular tool used to measure an angle in degrees. For example, two perpendicular lines create a 90-degree angle. The wide, flat side of the protractor should be aligned against one of the walls, with the second wall intersecting with one of the curved lines to measure the angle. An adjustable bevel gauge consists of a handle, and a blade which rotates and locks at any angle, making it useful for copying real-life angles onto baseboards and other trim. For either tool, you can take your reading then divide by two to get the angle for each cut piece of baseboard trim, as two pieces will meet to form the full angle. To ensure accuracy and prevent wastage of materials, always double-check your measurements before proceeding with the cut. If dealing with larger or more complex angles, you may also need a compound miter saw, a power tool that cuts using a large round blade to cut at different angles. This tool is designed to make precise bevel cuts, which is especially useful for cutting baseboards that will fit together at an odd angle, like in a bay window. Understanding how to properly measure angles will allow you to cut baseboards accurately and professionally. It ensures that the pieces fit together seamlessly, without any gaps or overlaps, contributing immensely to the overall aesthetic appeal of your room makeover. Precision in measuring and cutting angles is a skill that cannot be understated in importance when dealing with intricate tasks like baseboard and crown molding setups where every angle impacts the final result. Indeed, 1.1 Measuring the angle is a significant stepping stone to the greater topic of Understanding the Basics of Cutting Baseboard Angles. It's a combination of mathematical knowledge, spatial awareness, and detailed craftsmanship with tools, all essential components in putting together any interior design or construction project with excellence.

1.2 Identifying the Type of Angle

Article - In learning how to cut baseboard angles effectively, one critical step is 1.2, Identifying the Types of Angle. Understanding the variations in angles greatly impacts the precision with which you execute your woodwork. Essentially, there are four general types of angles; right angles, acute angles, obtuse angles, and straight angles. A right angle is exactly 90 degrees and is often used when you want two baseboard pieces to join perfectly. Its accuracy is paramount as it significantly affects the fit and finish of the end product. It's the most common angle utilized in baseboard fitting around the house except for a few exceptions such as when meeting with rounded or polygon walls. In contrast, an acute angle is less than 90 degrees. This type of angle is used in tight corners where two walls meet at a point sharper than a right angle. An obtuse angle, on the other hand, is more than 90 degrees but less than 180 degrees. This type of angle is used when dealing with walls that meet at a widely opened point. It can be a bit challenging to cut an obtuse baseboard angle correctly due to its broadness; however, with the right skillset and tools, it is achievable. Finally, a straight angle, also known as flat-angle, is 180 degrees. Its cutting typically applies to projects where you would want the baseboard to stretch continously in a straight line without any form of deviation. In essence, the need to ensure absolute accuracy in measuring and cutting these angles can't be overemphasized, as it would result in either a tight, perfect fit or a loose, messy fit. Moreover, learning to identify the type of angle you are planning to cut will enhance your precision in wood cutting. It will prepare you to effectively cut and fit baseboard moldings with fewer spaces, especially on inside and outside corners. Each type of angle requires different techniques for you to master, and the ability to identify them can increase the quality of your woodwork significantly. Therefore, the knowledge of identifying the type of angle is a vital tool in the Baseboard cutting task. It not only gives an edge to your competence as a woodcutter but also results in refined, professionally finished work. Feel free to explore the vast world of baseboard cutting angles, practice diligently and always remember that safety comes first in every woodwork project. With these, you can ensure perfection in your baseboard projects and look forward to more with the certainty of delivering top-notch woodworking projects. It's all about the basics; unlocking the type of angle well helps you master the essential skills necessary for cutting baseboard angles effectively. With this information, you're set to understand the mystery behind the precise and accurate cutting of baseboard angles.

1.3 Choosing the Right Tools

Choosing the Right Tools in cutting baseboard angles is a vital aspect that requires your attention. Remember, quality output begins with selecting the right tools for the job. For instance, to make the cutting process accurate and less daunting, you need a miter saw. A miter saw helps in making precise cuts at various angles. Sometimes, the project might require cutting at a 45-degree angle, and here, a miter saw becomes very instrumental. In such cases, the saw enables you to make bevel cuts, where it cuts the baseboard on an angle other than 90 degrees to the face side. Depending on your project's complexity, you may require a compound miter saw, which performs both bevel and miter cuts. Another crucial tool is the coping saw, indispensable for making back-cuts or coped joints, common when dealing with inside corners. To ensure the baseboards fit together seamlessly at the corners, you might also need a coping foot and angle finder for correctness. However, choosing the right tools does not only revolve around the cutting gear. You also need to consider other accompanying equipment such as a tape measure for acquiring accurate measurements, a pencil for marking, clamps for holding the baseboard in place during the cutting process, and protective gear such as goggles and gloves for safety. Moreover, appropriate maintenance and handling of these tools are equally important. This routine includes regular cleaning, sharpening (for cutting tools), and proper storage to prolong their lifespan and improve their performance. Lastly, user competence with these tools cannot be overstated. As much as having the right tools is paramount, knowing how to use them appropriately makes a significant difference in the outcome of your baseboard-cutting project. Thus, choosing the right tools signifies halfway success in understanding the basics of cutting baseboard angles. It's not merely about having the tools but concerns the quality of tools, knowing when and how to use them effectively, and ultimately, their maintenance. With these considerations, you can rest assured that your baseboard cutting process will be accurate, smooth, quick, and perhaps, enjoyable.

Preparing for the Cut

When it comes to executing a precise and efficient cut in woodworking or construction, preparation is key. This entails not just having the right tools, but also meticulously adhering to important steps such as marking the board, setting up the cutting area, and ensuring safety precautions are in place. Each element combines to ensure a perfect cut, minimizing waste, and preventing accidents. The first step, marking the board, involves clear delineation to guide the cut. It's more than just a hurried line - marks should be accurate to avoid wastage of materials and to ensure that the completed piece fits perfectly as intended. On the other hand, setting up the cutting area is about organizing the workspace for optimal functionality. A suitable environment goes a long way in ensuring efficiency and accuracy. Finally yet importantly, safety precautions can never be overstated. Implementing sufficient safety measures not only prevents avoidable accidents but also contributes to the quality of the cut. The process, though seemingly straightforward, has intrinsic details that are germane to the final outcome. Moving on to the first supporting step of the process, marking the board, it requires careful attention...

2.1 Marking the Board

As a precursor to physically cutting your baseboard angles, gaining a perfect edge largely relies on the practice of 'Marking the Board.' This section under 'Preparing for the Cut' guides you through the crucial steps for this prep phase, shaping your understanding of how to execute it flawlessly when you've got your baseboard and cutting tools ready. The core process of marking the baseboard involves outlining the exact cuts you need to make. Doing so would provide you with a clear-cut guideline to follow, eliminating any chance of error when the actual cutting begins. Start by measuring the length of the baseboard against the wall where it needs to fit. This length becomes your guide to mark the baseboard at the precise point where the cut must be made. It would be worthwhile to remember that miscalculations in this step could lead to cutting excessive lengths or leaving less, resulting in the piece not fitting as seamlessly as they should. Use a pencil to mark these points lightly, ensuring these marks could be easily removed after the cutting process. Avoid using colored markers which might leave a stain and ruin the aesthetics of your baseboard. To further increase accuracy, a straight edge or level can be used to draw a line at the spot where the cut should be made. This line plays a dual role – it helps visualize the cut to be made while making sure to maintain the symmetry of the cut's angle. Once you've marked your baseboard, it's time to decide on the perfect angle to make the cut. If your baseboard is going to connect with another baseboard at the corner, you’ll need a miter cut. If it is connecting against a flat surface, a regular straight cut would suffice. A dual-degree protractor can be used to measure the angle, which will help in setting the miter saw accordingly. If you're making a miter cut, make sure to mark both boards that the cut must correspond. There are adhesive or board clamps available which can support your baseboard during the process, lending stability and precision. In addition, if there are any intricate details or complex designs on the baseboard that need to be accounted for when cutting, these should be marked as well. The beauty of a well-fitted baseboard lies in its precision and aesthetics, so being detailed in this step is of great importance. This process of 'Marking the Board' is truly indispensable during the preparation for baseboard angle cuts. A proper understanding and execution of this process can largely impact the final outcome, making the difference between an average and a perfect fit. With the right tools at your disposal and a discerning eye for detail, your rigorous marking process sets the stage for a smooth cutting process and a perfectly angled baseboard to enhance your living spaces.

2.2 Setting Up the Cutting Area

Setting up your cutting area is a vital step in the process of cutting baseboard angles; it is often disregarded, but it makes the difference between a straightforward job and a complicated one. To start, you need to find an ideal, comfortable location with enough space for you to move around. An outdoor location like a garage or a yard is an excellent choice as it provides sufficient ventilation and helps to manage the sawdust produced during the process. Set up a firm, sturdy table or bench on which the miter saw will be placed; it needs to be at a comfortable height to prevent unnecessary strains that may cause discomfort or injuries. Ensure the miter saw is secured tightly to the bench or table to make it stable and prevent potential accidents. Also provide clearance space for the boards to move freely on either side of the saw without obstruction. Once you have the space, it's time to set up your tools. Your miter saw is essential, as it is used to make accurate, angled cuts on the baseboard. Make sure the saw is in proper working condition, its blades are sharp, and all its safety features are functioning well. A poorly maintained miter saw could lead to rough cuts or, worse yet, injury. Now, gather all the materials needed. Primarily, you'll need the baseboards you'll be cutting, but don't underestimate the importance of other tools like your tape measure, carpenter's square, and marking pencils. Keeping such tools close at hand will save you time and eliminate unnecessary interruptions in the cutting process that could disrupt your flow and concentration. Always keep safety gear such as safety glasses, work gloves, and ear protection nearby, they are an absolute requisite when working with power tools and materials such as baseboards. Proper lighting is another key aspect in setting up your cutting area. You need to have a clear, unobstructed view of your measurements and cut lines, especially when identifying and marking angles on the baseboard. Poor lighting could result in inaccurate cuts or even dangerous mishaps. Make sure the space is well-lit, either by natural light or with a supplemental work light. Lastly, you’ll want a system to manage the sawdust produced during the cutting process. This might not seem important at first, but prolonged exposure could lead to respiratory issues. Setting up a shop-vac or dust management system is a good practice, as is ensuring you have a suitable cleaning plan for after the work is done. In conclusion, setting up the cutting area effectively and attentively not only makes your work easier but also contributes significantly towards the quality of the baseboard angles you produce. It ensures you work in a safe, efficient environment, and sets a solid foundation for carrying out the rest of the project.

2.3 Ensuring Safety Precautions

2.3 Ensuring Safety Precautions

Safety precautions are essential when attempting to cut baseboard angles, and these measures should not be taken lightly. According to surveys taken by the United States Consumer Products Safety Commission, there were nearly 93,200 injuries related to power saws in 2018. These numbers highlight the importance of prioritizing safety when handling dangerous tools. Before starting to cut, ensure that you have all the necessary protective gear. This includes, but is not limited to, safety goggles to protect your eyes from flying debris and dust, earplugs to minimize the damage to your hearing from the loud noise the saw produces, and gloves to safeguard your hands from potential cuts and splinters. Wearing a mask can also be beneficial to avoid inhaling harmful dust particles and sawdust. Additionally, always assess and ensure that the work surface is safe and secure. The baseboard should be firmly clamped onto the working surface to prevent any unexpected movements during the cutting process. This ensures the cut is accurate and reduces the odds of accidents. Remember to positively control the saw at all times and avoid letting your fingers get excessively near the cutting edge. With power tools, allowing the tool to do the cutting is vital for safety. Forcing the saw may cause it to kick back, jam, or bind, which can result in personal injury or damage to the project. Allow the saw to reach its full speed before you start cutting and maintain a steady speed. The rush to complete the project might be strong, but staying safe is paramount. Lastly, maintain a work environment that is clean and clutter-free. Sawdust or small fragments of the wood lying around can potentially become a tripping hazard or ignite a fire. Regularly clean your workspace and keep flammable materials away from the saw. While these measures might seem tedious or time-consuming, they play a crucial role in preventing injuries. Whenever you're preparing for a cut, take the time to ensure your safety. After all, no baseboard is worth a trip to the emergency room. Whether you are a DIY enthusiast or a professional carpenter, understanding and implementing these precautions can safeguard you against potential hazards when cutting baseboard angles.Cutting the Baseboard Angles

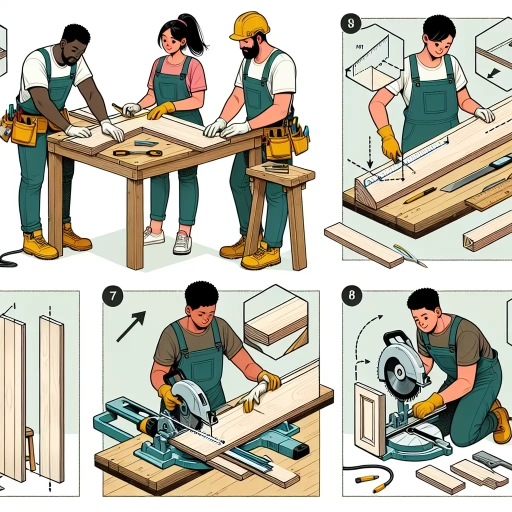

The process of cutting baseboard angles accurately is an essential aspect in carpentry, carrying enormous significance in the finished project's aesthetics and structural integrity. This article will delve into three powerful techniques to execute these cuts, each utilizing a different and readily available tool. First, we'll explore how to align and cut the perfect baseboard angles using a miter saw, a tool renowned for its precision and accuracy. Subsequently, we'll outline the methodology of employing a circular saw for this task, emphasizing the careful balance between power and precision. Finally, for those without access to power tools or seeking a more hands-on approach, we will discuss the traditional craft of utilizing a hand saw. These techniques, correctly applied, can garner flawless baseboard angles, regardless of the tools at your disposal. We commence with the first approach: wielding the versatile and precise miter saw.

3.1 Using a Miter Saw

3.1 Using a Miter Saw A miter saw plays a critical part in cutting baseboard angles and it is an efficient tool that provides precision and accuracy during the process. Primarily, the miter saw executes two types of cuts - a miter cut and a bevel cut. A miter cut involves a straight cut through the face of the wood, at an angle other than 90 degrees along the length of the wood width. This cut is most commonly used for trimming and molding projects, especially when cutting the corners of the trim or molding to fit together with a snug, professional finish. On the other hand, a bevel cut is conducted at an angle through the thickness of the board. For baseboards, the miter cut is more frequently used. To efficiently cut baseboard angles using a miter saw, you first need to mark the baseboard using a pencil to denote where the baseboard needs to be cut. Make sure the measurements are accurate, as this is crucial to the fit and finish of your baseboard trim. Next, adjust the miter saw to the angle you wish to cut. Most miter saws have angle markings on their base for common angles, but you can manually set any angle you need. Ensure the board is snug against the fence of the saw, which provides stability during the cut. Before you start cutting, double-check everything: the marked line should align with the blade, the angle of the saw matches the desired cut, and the board is well secured. While cutting, it’s essential to let the saw do the work. Push the blade into the board with a steady and controlled motion without forcing it. If the saw is forced into the material, it can cause inaccurate cuts, damaged material, or even injury. It’s also vital to be patient and let the saw completely stop before you raise it. Using a miter saw for cutting baseboard angles ensures straight lines and sharp, precise corners, giving the room a finished, professional appearance. Regardless of the complexity of the space's layout person can master the art of cutting baseboard angles with a miter saw, paying close attention to safety measures, including wearing protective eyewear and exercising caution while handling the saw. The mastered use of the miter saw in cutting baseboard angles indeed signs a beautifully executed trim work that compliments the overall room design.

3.2 Employing a Circular Saw

Cutting baseboard angles can be a tedious task, but it becomes significantly simplified and more efficient when you employ an effective tool - a circular saw. A circular saw adds precision and uniformity, making it an essential tool for cutting baseboard angles. A circular saw operates with a round saw blade, typically around 7-1/4 inches in size, equipped with sharp teeth that quickly cut through different types of materials, including baseboards. Using a circular saw demands caution. Always remember to set the correct depth of the cut on your saw: it should be just slightly more than the thickness of the baseboard materials. This prevents unnecessary damage to underlying materials and ensures safety while working. Equipped with an adjustable base, a circular saw allows you to determine the angle for the cut. For baseboard angles, 45-degree cuts are often what you need to achieve successful corner fitting. Consider marking the baseboard with a pencil before making the actual cut. Using a carpenter’s square for marking will give you an accurate guideline to follow with your circular saw. Make sure your circular saw blade is sharp, ensuring a clean, precise cut. Dull blades will result in rough cuts and potential wood damage. When using a circular saw, holding the tool correctly and securing the baseboard firmly can make a massive difference. Ensure the baseboard is firmly clamped down or adequately supported to prevent instability or movement during the cut. Start the saw away from the baseboard, then gently bring it into contact with the material. Move along the marked line at a steady pace, not forcing it, allowing the blade to cut through the baseboard. Remember, always wear safety gear, including safety glasses and hearing protection, when using a circular saw. It's essential to let the saw come to a complete stop before lifting it away from the cut. Also, make sure you're working in a well-ventilated area to avoid inhaling dust and debris. Lastly, with a circular saw, you can achieve a professional finish. Regular practice can perfect your technique, and once you master the skill of cutting baseboard angles using a circular saw, your DIY baseboard installation will look as good as any professional job. Perfecting the skill of using a circular saw takes time and practice but is a valuable skill for hobbyists, DIY home improvers, and professional carpenters. It is a versatile, efficient tool that simplifies the process of cutting baseboard angles, ensuring precision, efficiency, and a high-quality finish. Utilizing a circular saw effectively can accelerate the baseboard fitment process and result in a neat, visually pleasing finish that enhances the aesthetics of your space.

3.3 Utilizing a Hand Saw

of Cutting Mastery It is imperative to discuss one crucial element in the process of cutting baseboard angles; this is none other than the utility of a hand saw. Specifically, a miter saw could be the best tool to utilize when it involves intricate tasks such as cutting angles. This hand-operatd tool, although conventional, offers remarkable effectiveness and precision that can significantly enhance the overall result of the project. Though this might seem like an outmoded choice in our technologically advanced age of power tools, manual hand saws have qualities that still make them a golden pick amongst carpenters particularly for baseboard angle cutting. The hand saw allows more control as you gradually erode the baseboard, thereby ensuring that the cut remains accurate to the marked guidelines and influence a clean, crisp cut. Using a hand saw is a straightforward process. Begin by confirming the angle, which the baseboard needs to be cut at using an adjustable protractor or angle finder. Mark this angle on the baseboard, remembering to bear in mind which direction the cut needs to be made. Now, fix the baseboard in a miter box which has slots at commonly used angles. Aligning your mark with the slot that corresponds to your desired angle, hold the baseboard steady with either a clamp or your hand, making sure your fingers are well clear of the saw. With long, even strokes, begin cutting from one end to the other, applying even pressure and maintaining a steady speed. Continue this motion until the cut is complete and then gently pull the blade out of the groove. Manual hand saws, though require a level of physical input, provide a sense of ‘connection’ to the work that power tools might lack. This connection allows you to ‘feel’ the saw as it moves through the material, giving you a greater sense of control and understanding of the work. This type of insight can lead to more precise cuts and a higher quality finish. Apart from contributing to comprehensible accuracy, the utilization of a hand saw is particularly crucial when it comes to minimizing waste. With its thin blade, a hand saw implies a thinner kerf, or in simpler terms, the width of the material that is removed during cutting is much less relative to a bulkier power tool. Hence, using a hand saw, comparatively, leads to lesser waste. This ‘less is more’ concept is equally valid when considering the noise factor. A hand saw does not require an electricity supply to operate and, of course, makes significantly less noise than a power tool. This might well be a factor if you are working in a quiet residential area or if you are working at a time when you particularly want to minimize disruption. In utilizing a hand saw for cutting baseboard angles, it is equally critical to understand that efficiency lies in the technique adopted and not solely on the tool alone. From the correct body stance to the grip on the saw and the angle at which you make the cut all contribute to a perfect finish when cutting your baseboard angles. Despite advanced technologies and power tools, the humble hand saw unquestionably holds its edge in the craft of cutting baseboard angles and remains an essential tool in the carpentry arsenal.