How To Make Cornmeal

Cornmeal is a staple ingredient in many cuisines around the world, particularly in Latin American and Southern American cooking. It's a versatile ingredient that can be used in a variety of dishes, from baked goods to savory meals. However, many people are unaware of the process involved in making cornmeal from scratch. In this article, we will delve into the world of cornmeal production, exploring the basics of cornmeal, preparing corn for production, and processing it to achieve the desired texture and quality. To start, it's essential to understand the fundamentals of cornmeal, including its types, nutritional benefits, and uses in different recipes. By grasping these basics, you'll be better equipped to navigate the process of making cornmeal and experimenting with various recipes. Let's begin by understanding the basics of cornmeal.

Understanding the Basics of Cornmeal

Cornmeal is a staple ingredient in many cuisines, particularly in Latin American and Southern American cooking. It's a versatile ingredient that can be used in a variety of dishes, from baked goods to savory meals. But have you ever wondered what cornmeal is, how it's used, and what types are available? Understanding the basics of cornmeal can help you unlock its full potential in your cooking. In this article, we'll explore the different types of cornmeal, including fine, medium, and coarse, and discuss how to choose the right corn for cornmeal. We'll also delve into the various uses of cornmeal, from traditional dishes to modern recipes. So, let's start with the basics: what is cornmeal and how is it used?

What is Cornmeal and Its Uses

Cornmeal is a type of ground corn that is commonly used in cooking and baking. It is made by grinding dried corn kernels into a fine or medium texture, depending on the desired consistency. Cornmeal can be classified into different types, including fine, medium, and coarse, each with its own unique texture and usage. Fine cornmeal is often used in baked goods, such as cornbread and muffins, while medium cornmeal is commonly used in corn tortillas and other Latin American dishes. Coarse cornmeal, on the other hand, is often used in polenta and other savory dishes. Cornmeal is a good source of fiber, vitamins, and minerals, making it a nutritious addition to a variety of recipes. It can be used as a thickening agent, a coating for fried foods, or as a main ingredient in dishes like cornmeal mush and cornmeal pancakes. Additionally, cornmeal can be used to make corn flour, which is a popular ingredient in many gluten-free recipes. Overall, cornmeal is a versatile ingredient that can be used in a wide range of culinary applications.

Types of Cornmeal: Fine, Medium, and Coarse

Cornmeal, a staple ingredient in many cuisines, comes in various textures, each suited for specific recipes and cooking methods. The three primary types of cornmeal are fine, medium, and coarse, distinguished by their grind size and usage. Fine cornmeal, also known as corn flour, is the most finely ground and is often used in baked goods, such as cornbread, muffins, and cakes. It provides a delicate texture and subtle corn flavor, making it an excellent choice for desserts and sweet treats. Medium cornmeal, with its moderate grind size, is the most versatile and widely used type. It's perfect for cornbread, pancakes, waffles, and other breakfast items, as well as for coating fried foods, like chicken and fish. Coarse cornmeal, also known as polenta cornmeal, is the most coarsely ground and is often used in savory dishes, such as polenta, grits, and cornmeal mush. Its robust texture and nutty flavor make it an excellent choice for hearty, comforting meals. Understanding the differences between these types of cornmeal is essential for achieving the desired texture and flavor in your recipes.

Choosing the Right Corn for Cornmeal

Choosing the right corn for cornmeal is a crucial step in the process. There are several types of corn, each with its own unique characteristics, and not all are suitable for making cornmeal. The most commonly used types of corn for cornmeal are dent corn, flint corn, and sweet corn. Dent corn is the most popular choice, accounting for over 90% of the corn used for cornmeal production. It has a high starch content, which makes it ideal for grinding into a fine, smooth meal. Flint corn, on the other hand, has a harder outer layer and is often used for making coarser, more textured cornmeal. Sweet corn, while delicious for eating fresh, is not typically used for cornmeal as it has a higher moisture content and a sweeter flavor that can affect the final product. When selecting corn for cornmeal, it's also important to consider the color, as different colors can impart different flavors and textures. Yellow corn is the most commonly used, but white, pink, and blue corn can also be used to create unique and flavorful cornmeals. Ultimately, the type of corn chosen will depend on personal preference and the desired end product.

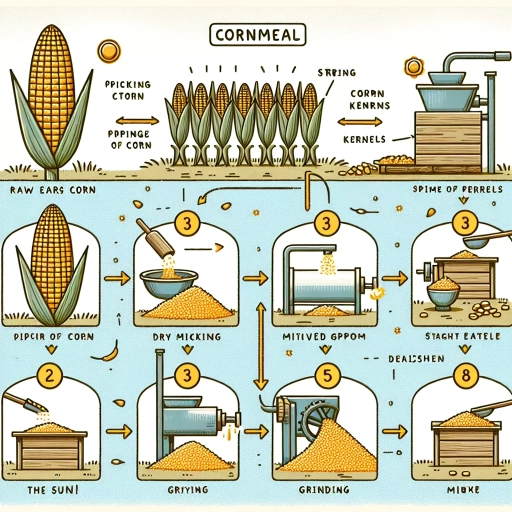

Preparing Corn for Cornmeal Production

Preparing corn for cornmeal production involves several crucial steps to ensure the final product is of high quality and safe for consumption. To achieve this, it is essential to focus on three key processes: drying corn to the right moisture level, removing impurities and debris from corn, and grinding or crushing corn into a coarse meal. Each of these steps plays a critical role in the overall quality of the cornmeal. Drying corn to the right moisture level is particularly important, as it helps prevent mold growth and spoilage. This step sets the stage for the entire production process, and it is crucial to get it right. By carefully controlling the moisture level of the corn, producers can help ensure that their cornmeal is fresh, flavorful, and safe to eat. With the importance of drying corn in mind, the first step in preparing corn for cornmeal production is to dry it to the right moisture level.

Drying Corn to the Right Moisture Level

Drying corn to the right moisture level is a crucial step in preparing corn for cornmeal production. The ideal moisture level for cornmeal production is between 13.5% and 14.5%. If the corn is too moist, it can lead to mold growth and spoilage, while corn that is too dry can be brittle and prone to breakage. To achieve the right moisture level, corn can be dried using various methods, including air drying, sun drying, or machine drying. Air drying involves spreading the corn out in a well-ventilated area, allowing it to dry slowly over time. Sun drying involves placing the corn in direct sunlight, either by spreading it out on a surface or by using a solar dryer. Machine drying uses a mechanical dryer to quickly and efficiently dry the corn to the desired moisture level. Regardless of the method used, it's essential to monitor the moisture level regularly to ensure that the corn is dried to the correct level. This can be done using a moisture meter or by performing a simple test, such as the "squeeze test," where a handful of corn is squeezed to check for moisture. By drying corn to the right moisture level, producers can ensure that their cornmeal is of high quality and safe for consumption.

Removing Impurities and Debris from Corn

Removing impurities and debris from corn is a crucial step in preparing it for cornmeal production. This process involves several methods to ensure that the corn is clean and free from contaminants. First, the corn is passed through a series of sieves or screens to remove any large debris, such as sticks, stones, or broken kernels. Next, the corn is subjected to air jets or blowers to separate the lighter impurities, such as chaff or dust, from the heavier corn kernels. Additionally, magnetic separators may be used to remove any metal fragments or other ferrous materials that may be present. Finally, the corn is washed with water to remove any remaining impurities, and then dried to a moisture level of around 15% to prevent spoilage. By removing impurities and debris, the quality of the cornmeal produced is improved, and the risk of contamination is minimized. This step is essential in ensuring that the final product is safe for consumption and meets the required standards.

Grinding or Crushing Corn into a Coarse Meal

Grinding or crushing corn into a coarse meal is a crucial step in the cornmeal production process. This process involves breaking down the corn kernels into smaller pieces to increase their surface area, making it easier to extract the desired nutrients and flavors. There are several methods to grind or crush corn, including using a grain mill, food processor, or blender. A grain mill is a specialized machine designed specifically for grinding grains, and it produces a consistent and high-quality coarse meal. A food processor or blender can also be used, but they may not produce as consistent a texture as a grain mill. When grinding or crushing corn, it's essential to monitor the temperature to prevent overheating, which can damage the corn and affect its nutritional value. The ideal temperature for grinding corn is between 100°F and 120°F (38°C to 49°C). Additionally, it's crucial to grind the corn in small batches to prevent clogging the machine and to ensure even grinding. The resulting coarse meal can be used to make a variety of cornmeal products, including cornbread, tortillas, and polenta. Overall, grinding or crushing corn into a coarse meal is a critical step in the cornmeal production process, and it requires attention to detail and the right equipment to produce high-quality results.

Processing Cornmeal to Desired Texture and Quality

Processing cornmeal to the desired texture and quality involves a series of steps that require attention to detail and a thorough understanding of the cornmeal's properties. To achieve the perfect cornmeal, it is essential to employ various techniques that enhance its texture, flavor, and shelf life. This process begins with sifting and winnowing to refine the cornmeal's texture, followed by heat treatment to enhance its flavor and shelf life. Finally, the cornmeal undergoes final milling to achieve the desired consistency. By carefully executing these steps, manufacturers can produce high-quality cornmeal that meets the demands of various applications, from baking and cooking to industrial uses. By refining the texture through sifting and winnowing, manufacturers can set the stage for the subsequent processing steps, ultimately resulting in a premium product. Sifting and winnowing to refine cornmeal texture is a critical initial step in this process.

Sifting and Winnowing to Refine Cornmeal Texture

Sifting and winnowing are two traditional techniques used to refine the texture of cornmeal, ensuring it meets the desired quality standards. Sifting involves passing the cornmeal through a fine-mesh sieve or screen to separate the finer particles from the coarser ones, resulting in a more uniform texture. This process helps to remove any lumps, bran, or germ particles that may be present, producing a smoother and more consistent cornmeal. On the other hand, winnowing is a process that uses air to separate the lighter particles from the heavier ones, allowing the finer particles to be collected and the coarser particles to be discarded. By combining sifting and winnowing, cornmeal producers can achieve a high-quality product with a refined texture that is ideal for various applications, including baking, cooking, and food processing. Regular sifting and winnowing also help to maintain the quality and freshness of the cornmeal, preventing the growth of mold and bacteria that can affect its texture and flavor. Overall, sifting and winnowing are essential steps in the processing of cornmeal, enabling producers to deliver a premium product that meets the expectations of consumers and food manufacturers alike.

Heat Treatment for Enhanced Flavor and Shelf Life

Heat treatment is a crucial step in processing cornmeal to enhance its flavor and shelf life. This process involves exposing the cornmeal to high temperatures to activate enzymes, break down starches, and caramelize natural sugars, resulting in a more complex and appealing flavor profile. Heat treatment also helps to inactivate enzymes that can cause spoilage, thereby extending the shelf life of the cornmeal. There are various heat treatment methods, including toasting, roasting, and extrusion, each with its own unique benefits and applications. Toasting, for example, is a gentle heat treatment that enhances the flavor and aroma of the cornmeal without compromising its nutritional content. Roasting, on the other hand, is a more intense heat treatment that can bring out a richer, nuttier flavor in the cornmeal. Extrusion, a high-temperature and high-pressure process, is often used to produce puffed or flaked cornmeal products with a crispy texture and long shelf life. Regardless of the method, heat treatment is an essential step in processing cornmeal to bring out its full flavor and nutritional potential.

Final Milling to Achieve Desired Cornmeal Consistency

Final milling is a crucial step in the cornmeal production process, as it determines the desired consistency of the final product. The goal of final milling is to break down the corn kernels into a uniform texture, which can range from fine to coarse, depending on the intended use of the cornmeal. To achieve the desired consistency, the milled corn is passed through a series of rollers or grinding stones, which crush and grind the kernels into smaller particles. The type of mill used, such as a hammer mill or a stone grinder, can also impact the final texture of the cornmeal. For example, a hammer mill will produce a finer texture, while a stone grinder will produce a coarser texture. Additionally, the speed and pressure of the milling process can also be adjusted to achieve the desired consistency. By carefully controlling the final milling process, manufacturers can produce cornmeal with a consistent texture that meets the needs of their customers, whether it's for baking, cooking, or other applications. Ultimately, the final milling step is critical in determining the quality and texture of the cornmeal, and it requires careful attention to detail to produce a high-quality product.