What Is Whisky Made Of

Whisky, a spirit steeped in tradition and craftsmanship, has captivated palates around the world for centuries. Its rich, complex flavor profile is a result of meticulous attention to detail in every stage of its creation. To fully appreciate the nuances of whisky, it is essential to understand its fundamental components, the intricate production processes, and the regional variations that define different types. This article delves into the heart of whisky, beginning with the **Ingredients and Raw Materials** that form its foundation. We will explore how grains such as barley, corn, and rye are carefully selected and processed to create the base for this beloved spirit. Next, we will examine the **Production Process and Techniques** that transform these raw materials into a refined liquor, including fermentation, distillation, and aging. Finally, we will discuss **Regional Variations and Regulations**, highlighting how different regions and countries impose unique standards and traditions that shape the final product. By understanding these elements, whisky enthusiasts can gain a deeper appreciation for the craftsmanship and diversity that make each bottle unique. Let us start by uncovering the essential **Ingredients and Raw Materials** that set the stage for this journey into the world of whisky.

Ingredients and Raw Materials

When it comes to crafting high-quality products, the selection and quality of ingredients and raw materials are paramount. This article delves into the critical components that underpin the production process, focusing on three key areas: Grains and Cereals, Water Quality and Source, and Yeast and Fermentation Process. Each of these elements plays a distinct yet interconnected role in determining the final product's taste, texture, and overall quality. Grains and Cereals form the foundational base for many food products, providing essential nutrients and structural integrity. Water Quality and Source are equally crucial, as even slight variations in water composition can significantly impact flavor profiles and product consistency. Lastly, Yeast and Fermentation Process are vital for transforming raw ingredients into something entirely new, adding depth and complexity through biochemical reactions. By understanding these core components, manufacturers can ensure that their products meet the highest standards of quality and consumer satisfaction. Let's begin by examining the importance of Grains and Cereals in this intricate process.

Grains and Cereals

Grains and cereals are the foundational ingredients in whisky production, playing a crucial role in determining the flavor, character, and quality of the final spirit. The primary grains used in whisky production include barley, corn, rye, wheat, and oats. Each grain contributes unique properties that influence the whisky's profile. Barley, for instance, is a staple in Scotch whisky and Irish whiskey due to its high enzyme content, which facilitates the malting process—a critical step where grains are soaked in water to activate enzymes that break down starches into fermentable sugars. Malting allows for the extraction of these sugars during mashing, a process where hot water is used to extract the sugars from the grains. Corn, on the other hand, is predominantly used in American whiskey styles such as bourbon and Tennessee whiskey. Corn adds a rich, sweet flavor profile due to its high sugar content. Rye grain is known for its spicy and dry characteristics, making it a key component in rye whiskey and some bourbon recipes. Wheat, with its milder flavor compared to rye, is often used in wheated bourbon to produce a smoother, more approachable taste. Oats are less commonly used but can add a creamy texture and subtle sweetness. The quality and type of grain can significantly impact the whisky's flavor profile. For example, the terroir of the region where the grains are grown can impart distinct flavors—Scottish barley may have a different character compared to barley grown in other parts of the world. Additionally, factors such as grain variety, soil quality, climate conditions, and farming practices all contribute to the final flavor of the whisky. The processing of grains also plays a vital role in whisky production. Milling or crushing the grains into a coarse flour called "grist" allows for better extraction during mashing. The mashing process involves mixing this grist with hot water to create a sugary liquid called wort, which is then fermented by yeast to produce a beer-like liquid known as wash. This wash is distilled to concentrate the alcohol and develop the complex flavors that define whisky. In summary, grains and cereals are not just raw materials but are integral components that shape the essence of whisky. Their selection, processing, and origin all contribute to the diverse range of flavors and characteristics found across different whisky styles. Understanding these grains provides insight into why certain whiskies have distinct profiles and why they are so highly regarded by connoisseurs and enthusiasts alike.

Water Quality and Source

When it comes to the production of whisky, one of the most critical components is water quality and source. Water constitutes a significant portion of whisky, typically making up about 60% of the final product. The quality and origin of this water can profoundly impact the flavor profile, character, and overall quality of the whisky. Whisky producers often emphasize the importance of using natural, pristine water sources. These sources can range from mountain springs to rivers and even underground aquifers. The purity and mineral content of the water are crucial factors; for instance, water with high levels of minerals such as calcium and magnesium can contribute to a smoother, more balanced flavor in the whisky. Conversely, water with high levels of impurities or contaminants can introduce undesirable flavors and aromas. The geographical location of the water source also plays a significant role. For example, Scottish distilleries often highlight their use of Highland spring water, which is renowned for its clarity and purity due to the region's rugged terrain and low levels of human activity. Similarly, Japanese whisky makers might use water from mountainous regions known for their pristine conditions. This emphasis on local and natural water sources not only enhances the flavor but also adds to the whisky's terroir—a concept borrowed from wine production that suggests the unique environmental conditions of a region contribute to the distinct characteristics of the product. In addition to its impact on flavor, water quality is also vital for ensuring the health and safety of the final product. Whisky producers must adhere to stringent quality control measures to ensure that their water supply meets or exceeds regulatory standards. This involves regular testing for contaminants such as heavy metals, bacteria, and other impurities that could compromise the quality or safety of the whisky. Moreover, sustainable practices in water management are increasingly important in modern whisky production. Many distilleries are now focusing on reducing their water footprint through efficient use and recycling practices. This not only helps in conserving this precious resource but also aligns with growing consumer expectations for environmentally responsible products. In summary, the quality and source of water are fundamental ingredients in whisky production. From influencing flavor profiles to ensuring safety standards and promoting sustainability, high-quality water is essential for crafting premium whisky. As such, it stands alongside grains, yeast, and other raw materials as a critical component in the art of whisky-making.

Yeast and Fermentation Process

Yeast and the fermentation process are pivotal components in the production of whisky, playing a crucial role in transforming raw ingredients into the complex, flavorful spirit that whisky enthusiasts savor. Yeast, a microorganism belonging to the fungus kingdom, is responsible for converting sugars present in the mash (a mixture of grains and water) into alcohol and carbon dioxide through fermentation. This biochemical reaction is the heart of whisky production, as it sets the stage for the subsequent distillation and aging processes. When yeast is added to the mash, it begins to consume the available sugars, primarily maltose and other simple carbohydrates derived from grains such as barley, corn, rye, or wheat. The yeast ferments these sugars, producing ethanol and carbon dioxide as byproducts. This fermentation process typically lasts several days, during which time the mixture, now called wort, undergoes significant changes in its chemical composition. The type of yeast used can influence the flavor profile of the whisky, with different strains producing varying levels of esters, aldehydes, and other compounds that contribute to the final character of the spirit. The conditions under which fermentation occurs are also critical. Factors such as temperature, pH levels, and the presence of nutrients can affect yeast activity and the resulting fermentation products. For instance, higher temperatures can lead to faster fermentation but may also introduce unwanted flavor compounds. Conversely, lower temperatures can result in a slower fermentation but often yield a cleaner, more desirable flavor profile. In addition to its role in alcohol production, yeast contributes to the development of whisky's complex flavor and aroma. During fermentation, yeast produces a range of secondary metabolites, including esters, phenolic compounds, and other volatile molecules that contribute to the whisky's bouquet and palate. These compounds can vary significantly depending on the specific yeast strain and fermentation conditions, making each batch of whisky unique. The fermentation process is closely monitored by distillers to ensure optimal conditions are maintained. This includes regular checks on temperature, specific gravity (a measure of sugar content), and pH levels. Once fermentation is complete, the fermented liquid is distilled to separate and concentrate the alcohol, marking the transition from wort to new make spirit. In summary, yeast and fermentation are essential elements in whisky production, transforming raw grains into a fermentable liquid that eventually becomes the rich, complex spirit known as whisky. The careful selection of yeast strains and meticulous control over fermentation conditions are key factors in determining the final quality and character of the whisky, underscoring the importance of these ingredients and processes in crafting this beloved beverage.

Production Process and Techniques

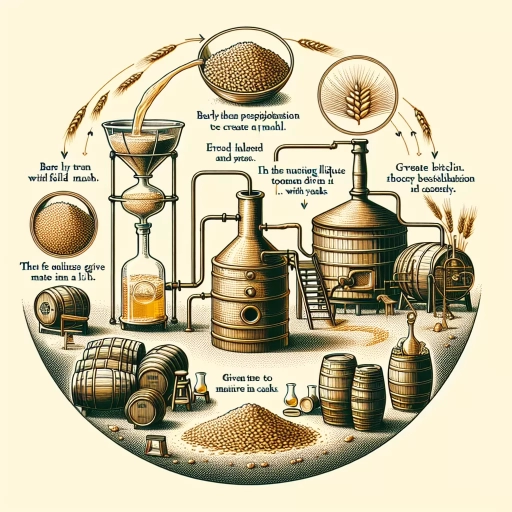

The production process of high-quality spirits, such as whiskey and rum, is a complex and multifaceted journey that involves several critical steps. At the heart of this process are three key techniques: Mashing and Malting, Distillation Methods, and Aging and Maturation. Each of these stages plays a pivotal role in shaping the final product's flavor, aroma, and overall character. The journey begins with Mashing and Malting, where grains are transformed into fermentable sugars. This initial step sets the foundation for the entire production process, influencing the type and amount of sugars available for fermentation. Following this, Distillation Methods come into play, where the fermented liquid is purified and concentrated to achieve the desired strength and flavor profile. Finally, Aging and Maturation allow the spirit to mature over time, absorbing flavors from the barrels and developing a rich, complex taste. Understanding these three stages is essential for appreciating the craftsmanship and science behind spirit production. Let's delve deeper into the first of these critical steps: Mashing and Malting.

Mashing and Malting

In the intricate journey of whisky production, mashing and malting are two crucial steps that lay the foundation for the final product's flavor and quality. **Malting** is the initial process where grains, typically barley, are soaked in water to activate enzymes that break down the starches into fermentable sugars. This step involves several stages: steeping, germination, and kilning. During steeping, the grains are immersed in water to rehydrate them, followed by germination where the grains are allowed to sprout, activating enzymes like amylase and glucanase. The germination process is halted by kilning, where the grains are dried in a controlled environment to preserve these enzymes and prevent further sprouting. This careful balance ensures that the grains retain their enzymatic activity while removing excess moisture. **Mashing** follows malting and involves mixing the malted grains with hot water in a large vessel called a mash tun. The hot water extracts the sugars from the malted grains, creating a sweet liquid known as wort. The mashing process typically involves multiple infusions of hot water at different temperatures to optimize sugar extraction. The first infusion, known as the strike, is usually around 162°F (72°C) to activate the enzymes fully. Subsequent infusions, or sparges, are done at slightly lower temperatures to extract as much sugar as possible without extracting unwanted compounds. The resulting wort is then separated from the spent grains and transferred to a kettle for boiling. The synergy between malting and mashing is paramount. Proper malting ensures that there are sufficient enzymes to convert starches into sugars during mashing, while effective mashing maximizes the extraction of these sugars. This dual process not only affects the yield but also influences the flavor profile of the whisky. For instance, variations in malting times or temperatures can alter the enzyme activity, impacting the types and amounts of sugars available for fermentation. Similarly, adjustments in mashing temperatures can influence the extraction of different compounds, contributing to the complexity and character of the whisky. In summary, mashing and malting are interdependent processes that form the backbone of whisky production. By carefully controlling these steps, distilleries can ensure consistent quality and flavor profiles in their whisky. The precision required in these processes underscores the craftsmanship and science involved in creating this beloved spirit. Whether it's the traditional methods used in Scotland or innovative techniques employed by modern distilleries, understanding mashing and malting is essential for appreciating the art of whisky-making.

Distillation Methods

Distillation is a crucial step in the whisky production process, transforming the fermented mash into a potent, flavorful spirit. There are several distillation methods employed in whisky production, each contributing to the unique characteristics of the final product. **Pot Distillation** is a traditional method often used for single malt and some blended whiskies. This process involves heating the fermented mash in copper pots, known as stills, to separate the alcohol from other components. The shape and size of the stills can significantly influence the flavor profile; for instance, taller stills tend to produce lighter, more delicate spirits, while shorter stills yield richer, fuller-bodied whiskies. The copper material also plays a role by reacting with sulfur compounds to remove unwanted flavors. **Column Distillation**, on the other hand, is commonly used for grain whiskies and some blended varieties. This method uses continuous distillation in tall, vertical columns called Coffey stills or column stills. Unlike pot distillation, column distillation allows for continuous operation and higher efficiency, producing a lighter spirit with fewer congeners (flavor compounds). This technique is particularly suited for grain whiskies that require a cleaner, more neutral base. **Hybrid Distillation** combines elements of both pot and column distillation. Some distilleries use a combination of pot stills for the initial distillation followed by column stills for further purification. This approach allows for greater control over the final flavor profile, blending the richness of pot-distilled spirits with the efficiency of column distillation. Regardless of the method used, distillation typically occurs in two stages: **low wines distillation** and **spirit distillation**. The first stage involves distilling the fermented mash to produce low wines, which are then redistilled to create the final spirit. Each stage refines the alcohol content and flavor profile, ensuring that only the desired compounds are retained. The choice of distillation method significantly impacts the character of the whisky. For example, pot-distilled whiskies often have a more robust flavor due to the retention of congeners, while column-distilled whiskies are generally smoother and more approachable. Understanding these different techniques is essential for appreciating the diversity within whisky production and the craftsmanship involved in creating each unique expression. In summary, distillation is an art that requires precision and skill to produce high-quality whisky. Whether through traditional pot distillation or modern column distillation, each method contributes to the rich tapestry of flavors found in various types of whisky. As part of the broader production process and techniques involved in making whisky, distillation stands out as a critical step that shapes the very essence of this beloved spirit.

Aging and Maturation

Aging and maturation are pivotal stages in the production process of whisky, significantly influencing its flavor, color, and overall character. This phase involves the storage of whisky in oak barrels, where it undergoes a series of complex chemical reactions and interactions with the wood. The aging process can last anywhere from a few years to several decades, depending on the type of whisky being produced. During maturation, whisky absorbs flavors and aromas from the oak barrels, which can impart notes of vanilla, caramel, and spices. The wood also allows a controlled amount of oxygen to interact with the whisky, which helps to soften its harsher elements and contribute to its smoothness. Additionally, a small percentage of the whisky evaporates through the barrel walls each year—a phenomenon known as the "angel's share"—which further concentrates the liquid and enhances its flavor profile. The type of oak used for aging is crucial; American white oak is commonly used for bourbon and Tennessee whiskey due to its tight grain structure, while European oak is often preferred for Scotch whisky because it imparts a richer, more complex flavor. The previous use of the barrels also plays a role; for example, bourbon barrels that have been used once can be repurposed for aging other types of whisky, adding unique characteristics. Temperature and humidity conditions in the warehouse where the barrels are stored also impact the aging process. Cooler temperatures slow down maturation, allowing for a more gradual development of flavors, while warmer temperatures accelerate the process. Similarly, higher humidity levels reduce evaporation rates, preserving more of the whisky's volume. Regular monitoring by skilled distillers ensures that the whisky matures optimally. They may rotate barrels to ensure even exposure to different environmental conditions within the warehouse or transfer whisky between barrels to achieve a desired balance of flavors. This meticulous attention to detail is essential for producing high-quality whisky that meets specific standards. In summary, aging and maturation are critical steps in whisky production that transform raw spirit into a sophisticated, flavorful beverage. The combination of oak barrels, environmental conditions, and careful management by distillers results in a richly complex whisky that reflects both tradition and craftsmanship. This process underscores the importance of patience and expertise in creating a premium whisky that stands out for its depth and character.

Regional Variations and Regulations

When exploring the world of whisky, it becomes evident that regional variations and regulations play a crucial role in defining the character and quality of this beloved spirit. From the stringent standards of Scotch whisky to the diverse practices in American whiskey production, and the unique traditions of other global whisky styles, each region brings its own distinct flavor profile and regulatory framework. This article delves into these differences, starting with the rigorous Scotch Whisky Regulations that ensure the authenticity and excellence of Scotland's iconic whisky. We will then transition to American Whiskey Standards, which offer a blend of tradition and innovation, before concluding with an overview of Other Global Whisky Styles that highlight the diverse approaches taken by distilleries around the world. By examining these regulatory landscapes, we gain a deeper understanding of what makes each type of whisky unique and why these regulations are essential for maintaining the integrity of this ancient craft. Let us begin our journey with the meticulous world of Scotch Whisky Regulations.

Scotch Whisky Regulations

Scotch Whisky is governed by a stringent set of regulations that ensure its quality, authenticity, and distinct character. These regulations are enshrined in the Scotch Whisky Regulations 2009, which were introduced to protect the integrity of Scotch Whisky and to provide consumers with clear guidelines on what constitutes this iconic spirit. According to these regulations, Scotch Whisky must be produced in Scotland, using malted barley, water, and yeast. The fermentation process must take place in Scotland, and the whisky must be distilled to no more than 94.8% ABV. Furthermore, Scotch Whisky must be matured for at least three years in oak casks within Scotland, which contributes to its rich flavor profile and distinctive color. The geographical location of the distillery plays a crucial role in defining the character of Scotch Whisky. Regional variations are a key aspect of Scotch Whisky's diversity, with different regions such as the Highlands, Lowlands, Islay, Speyside, and Campbeltown producing whiskies with unique flavor profiles. For instance, Islay whiskies are known for their smoky and peaty flavors due to the island's peat-rich soil and coastal environment. In contrast, Speyside whiskies are often described as fruity and floral, reflecting the region's fertile soil and mild climate. These regional differences are not just a matter of taste but are also protected by law to ensure that consumers can trust the origin and quality of the whisky they purchase. The regulations also specify labeling requirements to prevent misrepresentation. For example, the term "Scotch Whisky" must be used on the label, along with information about the age of the youngest whisky in the bottle if it is less than 10 years old. Additionally, terms like "Single Malt," "Blended Malt," "Blended Grain," and "Blended Scotch" have specific definitions to guide consumers in understanding what they are buying. This transparency helps maintain consumer trust and ensures that Scotch Whisky continues to be revered for its quality and authenticity. In summary, the regulations governing Scotch Whisky are designed to uphold its reputation as a premium spirit by ensuring adherence to traditional production methods, geographical authenticity, and clear labeling. These standards not only protect the industry but also enhance the consumer experience by providing a guarantee of quality and origin. Whether you are savoring a smoky Islay or a smooth Speyside, knowing that your Scotch Whisky meets these stringent regulations adds to its enjoyment and appreciation.

American Whiskey Standards

American whiskey, a staple of the country's spirits industry, is governed by a set of stringent standards that ensure its quality and authenticity. These standards are primarily outlined in the Federal Standards of Identity for Distilled Spirits, which dictate the production, labeling, and classification of various types of American whiskey. One of the most critical aspects is the requirement for American whiskey to be made from a grain mixture, or mash bill, that includes at least 51% of a specific grain such as corn, rye, wheat, or barley. For instance, bourbon whiskey must be made from at least 51% corn mash, while rye whiskey must contain at least 51% rye. The aging process is another crucial factor in American whiskey standards. Bourbon and Tennessee whiskey, for example, must be aged in new, charred oak barrels, which impart a rich color and complex flavor profile. The aging period can vary, but it must be at least two years for straight whiskey; otherwise, it cannot be labeled as such. Additionally, American whiskey cannot be aged in used barrels if it is to be labeled as "straight," ensuring that each batch has a distinct character shaped by the interaction with fresh oak. Regional variations also play a significant role in defining American whiskey. Tennessee whiskey, for instance, undergoes an additional step known as the Lincoln County Process, where the whiskey is filtered through sugar maple charcoal before aging. This process gives Tennessee whiskey its unique smoothness and flavor profile. In contrast, Kentucky bourbon is often associated with its rich, full-bodied taste due to the state's limestone-rich water and favorable climate for aging. Regulations also extend to labeling and marketing. The term "straight" on a label indicates that the whiskey has been aged for at least two years without any added flavorings or colorings. This transparency helps consumers understand the authenticity and quality of the product. Furthermore, geographical indications are protected; for example, bourbon can only be labeled as such if it is produced in the United States, with Kentucky being the most prominent region. In summary, American whiskey standards are designed to protect the integrity and quality of this beloved spirit. From the specific grain requirements to the aging processes and regional variations, these regulations ensure that each type of American whiskey maintains its unique character while adhering to high standards of production. This adherence not only satisfies legal requirements but also enhances consumer trust and appreciation for the craftsmanship involved in creating these distinctive whiskeys.

Other Global Whisky Styles

Beyond the well-known whisky styles of Scotland, Ireland, and the United States, there are numerous other global whisky styles that offer a diverse array of flavors and production methods. In Japan, for instance, whisky production is heavily influenced by Scottish traditions but with a distinct Japanese twist. Brands like Suntory and Nikka have gained international acclaim for their smooth, balanced whiskies that often incorporate local ingredients and unique aging processes. For example, the Yamazaki 18 Year Old is renowned for its rich, fruity flavors and subtle oak notes. In Canada, whisky production is characterized by its use of multi-grain recipes and a focus on blending. Canadian whiskies are often lighter and smoother, making them accessible to a wide range of palates. The regulations in Canada allow for a broader range of grains to be used, including corn, rye, barley, and wheat, which contributes to the distinctive flavor profiles of Canadian whiskies like Crown Royal and Forty Creek. India has also emerged as a significant player in the global whisky scene. Indian whisky producers such as Amrut and Paul John have been gaining recognition for their innovative approaches to whisky production. These distilleries often use local barley varieties and unique aging conditions due to India's tropical climate, resulting in robust and full-bodied whiskies with pronounced spice and fruit notes. In Europe, countries like Sweden and France are producing high-quality whiskies that reflect their regional characteristics. Swedish distilleries such as Mackmyra are known for their experimental approach, incorporating ingredients like cloudberry and birch sap into their recipes. French whisky producers like Armorik are leveraging the country's rich wine-making traditions to create whiskies with complex, vinous flavors. Australia and New Zealand are also making strides in the whisky world with their own distinct styles. Australian distilleries such as Starward and Lark are producing whiskies that are heavily influenced by the country's wine industry, often using Apera (Australian sherry) casks for aging. New Zealand's whisky scene is smaller but equally promising, with distilleries like Cardrona and The New Zealand Whisky Collection offering whiskies that showcase the country's pristine environment and unique terroir. Each of these global whisky styles is shaped by local regulations, climate conditions, and cultural traditions. For example, Japanese whisky must adhere to strict guidelines similar to those in Scotland, while Indian whisky producers face challenges related to the hot and humid climate which accelerates aging processes. Understanding these regional variations and regulations provides a deeper appreciation for the diversity and complexity of whisky production around the world. Whether it's the subtle nuances of Japanese whisky or the bold flavors of Indian whisky, each style offers a unique journey for whisky enthusiasts to explore and enjoy.