What Is An Arc Flash

An arc flash is a sudden and intense electrical explosion that can occur when there is an unintended electrical path, often resulting from a fault or short circuit. This phenomenon poses significant risks to both individuals and equipment, making it crucial to understand its definition, the hazards it presents, and the measures necessary for prevention. In this article, we will delve into the basics of arc flash, exploring what it is and how it occurs. We will also examine the risks and hazards associated with arc flash, including the potential for severe injuries and equipment damage. Finally, we will discuss essential prevention and safety measures to mitigate these risks. By understanding these aspects, individuals can better protect themselves and their workplaces from the dangers of arc flash. Let's begin by understanding the fundamental concept of arc flash in the next section: **Understanding Arc Flash: Definition and Basics**.

Understanding Arc Flash: Definition and Basics

Understanding Arc Flash is a critical topic for anyone working with electrical systems, as it poses significant risks to safety and equipment. An arc flash is a sudden, high-temperature electrical discharge that can occur when there is an unintended path of electricity, often resulting in severe injuries and damage. To grasp the concept fully, it is essential to delve into three key areas: **What is an Arc Flash?**, **Causes of Arc Flash**, and **Key Components Involved in Arc Flash**. By understanding what constitutes an arc flash, you can better appreciate the mechanisms behind this phenomenon. Identifying the causes of arc flash helps in preventing such incidents, while knowing the key components involved allows for more effective mitigation strategies. Starting with the basics, **What is an Arc Flash?** sets the foundation for comprehending this complex and hazardous event. This foundational knowledge is crucial for developing a deeper understanding of arc flash and its implications. Therefore, let's begin by exploring what exactly an arc flash is.

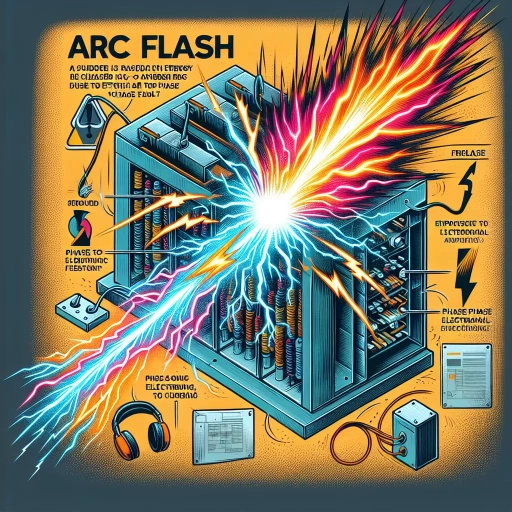

What is an Arc Flash?

An arc flash is a sudden, high-temperature electrical discharge that occurs when there is an unintended path of electricity, typically between two or more conductive objects. This phenomenon can happen in electrical systems, such as those found in industrial settings, data centers, and even residential environments. The arc flash is characterized by an intense burst of energy that can reach temperatures up to 35,000 degrees Fahrenheit, which is hotter than the surface of the sun. This extreme heat can cause severe burns, ignite flammable materials, and create a shockwave that can damage equipment and injure people nearby. The primary causes of arc flashes include human error during maintenance or repair work, equipment failure due to wear and tear or poor design, and environmental factors like moisture or dust accumulation. When an arc flash occurs, it releases a massive amount of energy in the form of light, heat, and sound. The blast can also generate a pressure wave that can knock people off their feet and cause hearing damage. Protective measures against arc flashes include wearing personal protective equipment (PPE) such as arc-rated clothing and face shields, following strict safety protocols during electrical work, and ensuring that electrical systems are properly maintained and inspected regularly. Understanding the basics of arc flashes is crucial for preventing these incidents and mitigating their impact. This involves recognizing potential hazards in electrical systems, adhering to safety standards and guidelines set by organizations like the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA), and providing comprehensive training to individuals who work with electrical equipment. By understanding what an arc flash is and how it can be prevented, individuals can significantly reduce the risk of injury or death associated with these dangerous events.

Causes of Arc Flash

Arc flash, a sudden and intense electrical explosion, is caused by a variety of factors that compromise the integrity of electrical systems. One primary cause is **inadequate maintenance** of electrical equipment, leading to worn-out or damaged components that can fail under normal operating conditions. **Human error**, such as improper use of tools or failure to follow safety protocols, also significantly contributes to arc flash incidents. For instance, using a metal tool near live electrical parts or not de-energizing equipment before performing maintenance tasks can trigger an arc flash. **Electrical overloads** and **short circuits** are another common cause. When electrical systems are subjected to more current than they are designed to handle, the insulation and conductors can fail, leading to an arc flash. Similarly, short circuits caused by faulty wiring or equipment malfunctions can create the conditions for an arc flash. **Dust and moisture** in the environment can also play a role by reducing the insulation properties of electrical components and increasing the likelihood of a fault. **Aging infrastructure** is another critical factor. Older electrical systems may have outdated designs or materials that are more prone to failure. Additionally, **inadequate training** of personnel working with electrical systems can lead to mistakes that result in arc flashes. Ensuring that workers are properly trained in safety procedures and electrical maintenance is crucial for preventing these incidents. **Poor design** of electrical systems can also contribute to the risk of arc flash. Systems that are not designed with safety in mind or those that do not adhere to current safety standards can increase the risk of electrical faults. Furthermore, **lack of regular inspections** means potential issues may go undetected until they cause a failure. Lastly, **equipment failure** due to manufacturing defects or improper installation can also lead to arc flash incidents. It is essential for organizations to ensure that all equipment meets relevant safety standards and is installed correctly to minimize this risk. Understanding these causes is crucial for implementing effective safety measures and reducing the risk of arc flash incidents in various settings. By addressing these factors through regular maintenance, proper training, and adherence to safety standards, organizations can significantly enhance electrical safety and protect their personnel from the dangers associated with arc flashes.

Key Components Involved in Arc Flash

When understanding arc flash, it is crucial to identify and comprehend the key components involved. An arc flash is a sudden, high-energy electrical discharge that occurs when there is an unintended path of electricity, typically between two conductors or between a conductor and ground. The primary components involved in an arc flash include **electrical energy sources**, **conductors**, **insulation**, and **protective equipment**. 1. **Electrical Energy Sources**: These are the power supplies that drive electrical currents. Common sources include transformers, generators, and electrical panels. The voltage and current levels from these sources determine the potential severity of an arc flash. 2. **Conductors**: These are materials that allow electricity to flow through them, such as wires, busbars, and circuit breakers. Conductors can be exposed or insulated, and their condition significantly affects the likelihood of an arc flash. 3. **Insulation**: Insulation materials are used to prevent electrical current from flowing where it should not. However, if insulation fails due to wear, damage, or improper installation, it can lead to an arc flash. Regular inspection and maintenance of insulation are essential to prevent such incidents. 4. **Protective Equipment**: This includes personal protective equipment (PPE) like arc-rated clothing, helmets, gloves, and safety glasses, as well as electrical protective devices such as circuit breakers and fuses. Proper use of protective equipment can mitigate the severity of injuries during an arc flash. Additionally, other critical factors include **arc flash boundaries**—the distances from the potential arc flash source within which a person could receive a second-degree burn—and **incident energy levels**, which quantify the amount of thermal energy released during an arc flash. Understanding these components and factors is vital for developing effective safety protocols and ensuring compliance with regulatory standards such as those set by the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA). By recognizing and addressing these key components, individuals can better understand how to prevent arc flashes and protect themselves and others from the severe consequences associated with these electrical events. Regular training, proper maintenance of electrical systems, and adherence to safety guidelines are all essential in minimizing the risk of arc flashes in various industrial settings.

Risks and Hazards Associated with Arc Flash

Arc flash, a sudden and intense electrical explosion, poses significant risks and hazards that can have devastating consequences. This article delves into the multifaceted dangers associated with arc flash, highlighting three critical areas: Physical Injuries and Fatalities, Equipment Damage and Downtime, and Environmental and Secondary Hazards. Physical injuries from arc flash can be severe, often resulting in burns, hearing loss, and even fatalities due to the extreme heat and pressure generated. Equipment damage is another major concern, as an arc flash can destroy electrical equipment and lead to costly downtime. Additionally, environmental and secondary hazards such as fires, toxic fumes, and structural damage must be considered. Understanding these risks is crucial for developing effective safety protocols to mitigate the impact of arc flash incidents. By examining these aspects in detail, we can better prepare for and respond to these dangerous events. Let us first explore the immediate and often catastrophic impact on human life: Physical Injuries and Fatalities.

Physical Injuries and Fatalities

Physical injuries and fatalities resulting from arc flash incidents are severe and often devastating. An arc flash, a sudden release of electrical energy, can generate temperatures up to 35,000 degrees Fahrenheit, hotter than the surface of the sun. This intense heat can cause third-degree burns, even if the victim is several feet away from the source. The blast also produces a shockwave that can knock individuals off their feet, leading to falls and blunt force trauma. Additionally, the explosion can propel metal shrapnel and other debris at high speeds, causing lacerations and penetrating injuries. The noise from an arc flash can be as loud as a gunshot, potentially causing permanent hearing damage. Moreover, the flash itself can cause temporary or permanent vision loss due to the intense light emitted. In many cases, these injuries are fatal; according to various studies, arc flash incidents result in a significant number of workplace deaths each year. The severity of these injuries underscores the critical importance of adhering to safety protocols and wearing appropriate personal protective equipment (PPE) when working with electrical systems to mitigate these risks. Employers must also ensure that all electrical equipment is properly maintained and that employees are adequately trained in arc flash safety procedures to prevent such tragedies.

Equipment Damage and Downtime

Equipment damage and downtime are significant consequences of arc flash incidents, posing substantial risks to both the integrity of electrical systems and overall operational efficiency. When an arc flash occurs, the intense heat and energy released can cause severe damage to electrical equipment, including circuit breakers, switchgear, and other components. This damage often necessitates costly repairs or even complete replacement of the affected equipment, leading to extended periods of downtime. The financial impact is twofold: not only are there direct costs associated with repairing or replacing damaged equipment, but there are also indirect costs due to lost productivity and potential delays in critical operations. Moreover, the downtime resulting from an arc flash incident can have far-reaching implications. In industrial settings, such as manufacturing plants or data centers, even a short period of downtime can result in significant losses. For instance, in a manufacturing environment, production lines may come to a halt, leading to missed deadlines and lost revenue. Similarly, in data centers, downtime can disrupt critical IT services, affecting businesses that rely on continuous data availability. The ripple effect of such disruptions can extend beyond the immediate site of the incident, impacting supply chains and customer satisfaction. Additionally, the process of restoring damaged equipment to operational status is often complex and time-consuming. It requires specialized expertise and may involve extensive testing to ensure that the repaired or replaced components meet safety standards. This adds another layer of complexity to the recovery process, further prolonging the period of downtime. In terms of safety, equipment damage from an arc flash also raises concerns about future reliability and potential for further incidents. Damaged components may not function as intended, increasing the risk of subsequent electrical failures or even another arc flash event. Therefore, thorough inspection and testing are crucial before returning the equipment to service. To mitigate these risks, proactive measures such as regular maintenance, adherence to safety protocols, and the use of arc flash protective devices are essential. Implementing these strategies can help prevent arc flash incidents from occurring in the first place, thereby reducing the likelihood of equipment damage and associated downtime. By prioritizing electrical safety and investing in preventive measures, organizations can minimize the financial and operational impacts of arc flash incidents, ensuring continuous and reliable operation of their electrical systems.

Environmental and Secondary Hazards

Environmental and secondary hazards are critical considerations when assessing the risks associated with arc flash incidents. These hazards can significantly amplify the severity of an arc flash event, leading to more extensive damage and increased risk to personnel and equipment. **Environmental Hazards:** 1. **Fire and Explosion:** Arc flashes can ignite flammable gases, vapors, or dusts present in the environment, leading to fires or explosions. This is particularly dangerous in industrial settings where such substances are common. 2. **Toxic Gases:** The intense heat from an arc flash can release toxic gases from burning materials, posing a significant health risk to those in the vicinity. 3. **Structural Damage:** The explosive force of an arc flash can cause structural damage to buildings or equipment, potentially leading to collapse or further hazards. 4. **Weather Conditions:** Inclement weather such as rain or high winds can exacerbate the effects of an arc flash by spreading electrical discharges or complicating rescue efforts. **Secondary Hazards:** 1. **Shrapnel and Debris:** The explosive nature of an arc flash often results in flying shrapnel and debris, which can cause injuries even if the individual is not directly exposed to the electrical discharge. 2. **Sound Waves:** The blast from an arc flash generates a loud noise that can cause hearing damage or disorientation. 3. **Thermal Burns:** Beyond the immediate electrical injury, the intense heat generated by an arc flash can cause severe thermal burns to anyone nearby. 4. **Equipment Failure:** An arc flash can lead to the failure of critical equipment, disrupting operations and potentially causing additional hazards such as loss of power or control over safety systems. Understanding these environmental and secondary hazards is essential for developing comprehensive safety protocols and mitigating the overall risk associated with arc flash incidents. By acknowledging these factors, organizations can better protect their personnel and assets from the multifaceted dangers posed by arc flashes. This includes implementing robust safety measures such as regular maintenance, proper personal protective equipment (PPE), and emergency response plans tailored to address both primary and secondary hazards effectively.

Prevention and Safety Measures for Arc Flash

Preventing and mitigating the risks associated with arc flash incidents is crucial for ensuring the safety of electrical workers and maintaining operational integrity. Arc flash, a sudden and intense electrical explosion, can cause severe injuries and fatalities. To address this hazard effectively, it is essential to implement a comprehensive approach that includes three key components: Personal Protective Equipment (PPE), Electrical System Design and Maintenance, and Training and Safety Protocols. Personal Protective Equipment (PPE) is the first line of defense against arc flash hazards. High-quality PPE, such as arc-rated clothing, gloves, and face shields, can significantly reduce the severity of injuries in the event of an arc flash. Electrical System Design and Maintenance play a critical role in preventing arc flash incidents. Properly designed electrical systems with safety features like arc flash detection and mitigation devices can minimize the risk of such events. Regular maintenance ensures that all electrical components are in good working condition, reducing the likelihood of faults that could lead to an arc flash. Training and Safety Protocols are equally important as they equip workers with the knowledge and skills necessary to handle electrical systems safely. Comprehensive training programs and adherence to strict safety protocols help in identifying potential hazards and taking preventive measures. By focusing on these three areas—starting with the critical importance of Personal Protective Equipment (PPE)—we can significantly enhance workplace safety and reduce the risk of arc flash incidents.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is a crucial component of prevention and safety measures for arc flash incidents. Arc flashes, which are sudden and intense electrical discharges, can cause severe injuries and fatalities. To mitigate these risks, PPE must be selected and used in accordance with the specific hazards present. Here are the key elements of PPE for arc flash protection: 1. **Arc-Rated Clothing**: This includes jackets, pants, shirts, and coveralls made from materials that are resistant to the thermal effects of an arc flash. These garments are rated for their ability to protect against various levels of arc energy, measured in calories per square centimeter (cal/cm²). 2. **Helmets and Face Shields**: These protect the head and face from the intense heat and flying debris generated by an arc flash. Helmets often have face shields or visors that are made from materials like polycarbonate or fiberglass. 3. **Gloves**: Insulated gloves provide both electrical insulation and thermal protection. They should be rated for the voltage level being worked on and have an arc rating to ensure they can withstand the thermal energy of an arc flash. 4. **Eye Protection**: Safety glasses or goggles with side shields are essential to protect the eyes from flying particles and intense light. For higher risk situations, face shields may be used in addition to safety glasses. 5. **Footwear**: Arc-rated footwear includes boots that are insulated and made from materials resistant to thermal hazards. They should also meet electrical safety standards. 6. **Hearing Protection**: Arc flashes can produce loud noises that could damage hearing, so earplugs or earmuffs may be necessary. 7. **Balaclavas and Hoods**: These provide additional protection for the neck and head area, ensuring comprehensive coverage against thermal hazards. When selecting PPE for arc flash protection, it is critical to follow industry standards such as those set by the National Fire Protection Association (NFPA) 70E in the United States or similar standards in other countries. The PPE should be chosen based on the calculated arc flash hazard analysis for the specific task being performed. Regular inspection and maintenance of PPE are also essential to ensure its effectiveness in preventing injuries during an arc flash event. By wearing appropriate PPE, workers can significantly reduce their risk of injury when working with electrical systems that could potentially produce an arc flash.

Electrical System Design and Maintenance

Electrical system design and maintenance are crucial components in preventing and mitigating the risks associated with arc flash incidents. Effective design begins with adhering to industry standards such as those set by the National Electric Code (NEC) and the Institute of Electrical and Electronics Engineers (IEEE). Engineers must ensure that electrical systems are designed with safety in mind, incorporating features like arc-resistant switchgear, proper grounding, and adequate insulation. Regular maintenance is equally important; it involves routine inspections to identify potential hazards such as worn or damaged components, loose connections, and overheating equipment. Maintenance personnel should follow strict protocols for de-energizing equipment before performing work, using lockout/tagout procedures to prevent accidental start-ups. Additionally, training programs for maintenance staff are essential to ensure they understand the risks of arc flash and how to safely perform their duties. The use of personal protective equipment (PPE) rated for the specific arc flash hazard level is also mandatory during maintenance tasks. By combining robust design principles with diligent maintenance practices, the likelihood of an arc flash event can be significantly reduced, thereby enhancing overall electrical system safety and reliability. This proactive approach not only protects personnel but also minimizes downtime and economic losses resulting from electrical system failures or accidents.

Training and Safety Protocols

Training and safety protocols are crucial components in the prevention and mitigation of arc flash incidents. These protocols ensure that personnel are well-equipped with the knowledge and skills necessary to handle electrical systems safely. Here are some key aspects: 1. **Comprehensive Training**: Regular training sessions should be conducted to educate workers on the risks associated with arc flash, how to identify potential hazards, and the proper use of personal protective equipment (PPE). Training should include hands-on exercises and simulations to reinforce learning. 2. **Risk Assessment**: Conduct thorough risk assessments to identify areas where arc flash hazards exist. This involves analyzing electrical systems, equipment, and work procedures to determine the likelihood and potential severity of an arc flash event. 3. **Standard Operating Procedures (SOPs)**: Develop and enforce strict SOPs for working with electrical systems. These procedures should outline safe practices for tasks such as maintenance, repairs, and inspections. 4. **Personal Protective Equipment (PPE)**: Ensure that all personnel working in areas where arc flash hazards are present wear appropriate PPE. This includes arc-rated clothing, gloves, safety glasses, and face shields that meet or exceed industry standards like those set by NFPA 70E. 5. **Lockout/Tagout Procedures**: Implement robust lockout/tagout procedures to ensure that electrical equipment is de-energized before any maintenance or repair work begins. This prevents accidental start-ups that could lead to an arc flash. 6. **Regular Maintenance**: Schedule regular maintenance checks on electrical equipment to prevent wear and tear that could increase the risk of an arc flash. This includes inspecting for signs of overheating, corrosion, or other damage. 7. **Emergency Response Plans**: Develop and regularly update emergency response plans that include procedures for responding to an arc flash incident. This should include first aid training for burns and other injuries that may result from an arc flash. 8. **Audits and Compliance**: Conduct regular audits to ensure compliance with safety protocols and industry standards. This helps identify any gaps in training or adherence to safety procedures and allows for prompt corrective action. 9. **Documentation**: Maintain detailed records of training sessions, risk assessments, maintenance activities, and any incidents involving arc flash. This documentation is essential for continuous improvement and compliance with regulatory requirements. 10. **Continuous Improvement**: Encourage a culture of safety where employees feel empowered to report any safety concerns or suggest improvements to existing protocols. This fosters a proactive approach to safety and helps in continuously refining training and safety protocols. By implementing these measures, organizations can significantly reduce the risk of arc flash incidents and ensure a safer working environment for their employees. Effective training and adherence to safety protocols are key to preventing injuries and fatalities associated with electrical hazards.