What Is A Shell Structure

Shell structures are a fascinating and versatile form of engineering design, characterized by their thin, curved surfaces that provide exceptional strength and stability. These structures, often seen in nature and replicated in human-made designs, have been a cornerstone of architectural and engineering innovation for centuries. From the intricate shells of mollusks to the grand domes of historical buildings, shell structures have captivated both scientists and the general public alike. This article delves into the world of shell structures, beginning with an **Introduction to Shell Structures**, where we explore the fundamental principles and historical context behind these remarkable designs. We will then examine the **Design and Construction of Shell Structures**, highlighting the advanced techniques and materials used to build these complex forms. Finally, we will discuss **Applications and Examples of Shell Structures**, showcasing their diverse uses in modern architecture, engineering, and beyond. By understanding these aspects, we can appreciate the ingenuity and functionality that make shell structures so compelling. Let us start by uncovering the essence of shell structures in our first section: **Introduction to Shell Structures**.

Shell structures are a fascinating and versatile form of engineering design, characterized by their thin, curved surfaces that provide exceptional strength and stability. These structures, often seen in nature and replicated in human-made designs, have been a cornerstone of architectural and engineering innovation for centuries. From the intricate shells of mollusks to the grand domes of historical buildings, shell structures have captivated both scientists and the general public alike. This article delves into the world of shell structures, beginning with an **Introduction to Shell Structures**, where we explore the fundamental principles and historical context behind these remarkable designs. We will then examine the **Design and Construction of Shell Structures**, highlighting the advanced techniques and materials used to build these complex forms. Finally, we will discuss **Applications and Examples of Shell Structures**, showcasing their diverse uses in modern architecture, engineering, and beyond. By understanding these aspects, we can appreciate the ingenuity and functionality that make shell structures so compelling. Let us start by uncovering the essence of shell structures in our first section: **Introduction to Shell Structures**.Introduction to Shell Structures

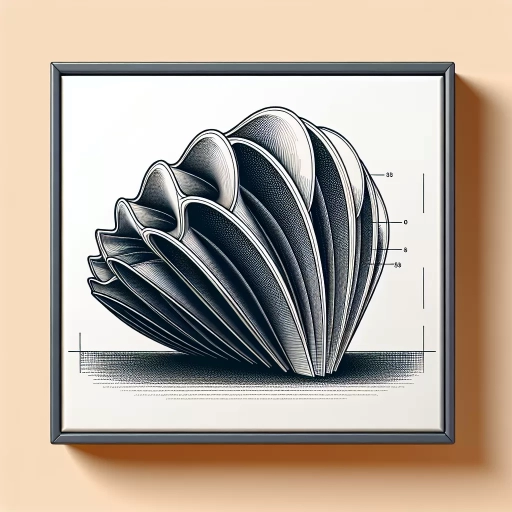

Shell structures, characterized by their curved and continuous surfaces, have been a cornerstone of engineering and architecture for centuries. These innovative designs offer exceptional strength, stability, and aesthetic appeal, making them indispensable in various fields. To fully appreciate the significance of shell structures, it is essential to delve into their definition and historical context, understanding how they have evolved over time. This journey begins with the early applications and theoretical foundations that laid the groundwork for modern shell structures. Additionally, exploring the diverse types of shell structures reveals the versatility and adaptability of these designs, from domes and arches to hyperbolic paraboloids and folded plates. Finally, recognizing the importance of shell structures in engineering and architecture highlights their role in pushing the boundaries of what is possible in construction, ensuring both functionality and beauty. By examining these aspects, we can gain a comprehensive understanding of why shell structures remain a vital component of contemporary design. Let us start by defining and tracing the historical context of these remarkable structures.

Definition and Historical Context

A shell structure, by definition, is a thin, curved or bent element that derives its strength and stability from its shape and the material properties of its constituent parts. Unlike beams or columns, which resist loads primarily through bending and axial forces, shell structures distribute loads across their surface, leveraging the inherent rigidity of their curved geometry to achieve remarkable strength-to-weight ratios. This unique characteristic makes them ideal for applications where large spans and minimal material usage are critical, such as in architectural domes, aircraft fuselages, and pressure vessels. Historically, the concept of shell structures dates back to ancient civilizations where natural forms like eggshells and seashells inspired early builders. The Pantheon in Rome, built in 126 AD, is one of the earliest examples of a large-scale shell structure. Its dome, constructed from concrete and brick-faced masonry, stands as a testament to the ingenuity of ancient engineers who understood the structural benefits of curved shapes. In the 19th century, the development of new materials like iron and steel further expanded the possibilities for shell construction. The Crystal Palace in London, designed by Joseph Paxton for the Great Exhibition of 1851, exemplifies this era's innovative use of glass and metal in creating large, lightweight structures. The 20th century saw significant advancements in shell design with the advent of reinforced concrete and the work of visionary architects like Antoni Gaudí and Eero Saarinen. Gaudí's Sagrada Família in Barcelona features intricate, parabolic arches that not only provide structural support but also create a visually stunning interior space. Saarinen's TWA Terminal in New York City, with its sweeping, wing-like roofline, is another iconic example of modern shell architecture. These structures not only pushed the boundaries of engineering but also redefined aesthetic standards in building design. Theoretical understanding of shell structures has evolved alongside technological advancements. Mathematicians and engineers have developed sophisticated models to analyze and predict the behavior of shells under various loads. The work of scientists like Stephen Timoshenko and Theodore von Kármán laid the foundation for modern shell theory, enabling designers to optimize their creations for maximum efficiency and safety. Today, computational methods and finite element analysis allow for precise simulations and optimizations that were previously unimaginable. In contemporary engineering and architecture, shell structures continue to play a vital role. They are used in aerospace engineering for lightweight yet robust aircraft components; in civil engineering for large-span roofs and bridges; and in industrial design for pressure vessels and storage tanks. The versatility and efficiency of shell structures make them an indispensable tool in modern construction, combining functional necessity with aesthetic appeal to create some of the most impressive and enduring structures of our time. Understanding the historical context and definition of shell structures provides a rich backdrop for appreciating their significance and ongoing relevance in engineering and architecture today.

Types of Shell Structures

Shell structures are versatile and efficient forms of construction that have been utilized across various engineering disciplines, from civil and architectural to aerospace and marine engineering. These structures are characterized by their thin, curved shapes that provide exceptional strength and stability while minimizing material usage. There are several types of shell structures, each with unique characteristics and applications. 1. **Dome Shells**: These are perhaps the most recognizable type of shell structure, often seen in architectural landmarks such as the Pantheon in Rome or the U.S. Capitol Building. Dome shells distribute loads evenly across their surface, making them ideal for covering large areas like stadiums, auditoriums, and public buildings. 2. **Cylindrical Shells**: Commonly used in industrial settings, cylindrical shells are found in tanks, pipelines, and silos. Their continuous curvature allows them to withstand internal pressures efficiently, making them suitable for storing liquids and gases. 3. **Spherical Shells**: These structures are essentially domes that extend into a complete sphere. Spherical shells offer maximum volume for a given surface area and are often used in pressure vessels, such as those found in chemical plants or spacecraft. 4. **Hyperbolic Paraboloid Shells**: Also known as "saddle" shells due to their shape resembling a saddle, these structures combine the properties of both domes and cylindrical shells. They are frequently used in roofing systems where they provide excellent drainage and structural integrity. 5. **Elliptical Shells**: These shells have an elliptical cross-section and are typically used in applications where a combination of strength and aesthetic appeal is desired. They can be seen in some modern architectural designs where unique shapes are preferred. 6. **Conical Shells**: Conical shells are used in structures like chimneys, silos, and some types of roofs. Their tapered shape allows them to resist wind loads effectively while providing a simple yet robust design. 7. **Folded Plate Structures**: While not strictly a single continuous shell, folded plate structures consist of multiple flat plates connected at angles to form a shell-like configuration. These are often used in roofing systems where they offer flexibility in design and good structural performance. 8. **Free-Form Shells**: With advancements in computational design and fabrication techniques, free-form shells have become increasingly popular. These structures can take on any shape that is mathematically defined, allowing architects to create complex geometries that would be impossible with traditional methods. Each type of shell structure has its own set of advantages and is suited to specific applications based on factors such as load distribution, material efficiency, and aesthetic considerations. Understanding these different types is crucial for engineers and architects who aim to leverage the unique benefits that shell structures offer in terms of strength, efficiency, and design flexibility. By selecting the appropriate type of shell structure for a given project, professionals can ensure optimal performance while minimizing material usage and construction costs.

Importance in Engineering and Architecture

In the realm of engineering and architecture, the importance of shell structures cannot be overstated. These thin, curved structures, which derive their strength from their shape rather than their thickness, play a crucial role in modern construction. Shell structures are ubiquitous in various forms, from the iconic domes of ancient buildings to the sleek, aerodynamic designs of contemporary architecture. Their significance lies in their ability to provide exceptional strength-to-weight ratios, making them ideal for large-span structures such as stadiums, auditoriums, and even spacecraft. One of the primary reasons shell structures are so vital is their efficiency in distributing loads. Unlike traditional beam and column systems, which can be heavy and cumbersome, shell structures distribute forces evenly across their surface, minimizing the need for additional support. This not only reduces material usage but also allows for more open and unobstructed spaces, enhancing aesthetic appeal and functional versatility. For instance, the Sydney Opera House, with its series of interlocking arches, exemplifies how shell structures can create visually stunning and highly functional spaces. Moreover, shell structures offer unparalleled flexibility in design. Their curved shapes can be tailored to meet specific architectural visions while adhering to stringent engineering standards. This adaptability is particularly evident in the design of bridges, where shell structures can span long distances without the need for intermediate supports. The Gateway Arch in St. Louis, Missouri, is a prime example of how a shell structure can be both a marvel of engineering and a symbol of cultural significance. From an engineering perspective, the analysis and design of shell structures involve complex mathematical models and advanced computational techniques. The study of shell structures has led to significant advancements in materials science and structural mechanics, driving innovation in fields such as aerospace engineering and civil construction. For example, the development of composite materials has enabled the creation of lightweight yet incredibly strong shells that are used in everything from aircraft fuselages to wind turbine blades. In addition to their technical merits, shell structures also hold historical and cultural importance. Many ancient civilizations, such as the Romans and Greeks, employed shell-like structures in their architecture, often as domes or vaults. These early examples not only demonstrate the enduring appeal of curved forms but also highlight the ingenuity of past engineers and architects who developed these techniques without modern computational tools. In conclusion, the importance of shell structures in engineering and architecture is multifaceted. They offer a unique combination of structural efficiency, design flexibility, and aesthetic appeal that makes them indispensable in modern construction. Whether it's the grandeur of historical landmarks or the cutting-edge technology of contemporary designs, shell structures continue to inspire and influence both engineers and architects alike. As we delve into the intricacies of shell structures, it becomes clear that their significance extends beyond mere functionality; they represent a synthesis of art, science, and human ingenuity that shapes our built environment in profound ways.

Design and Construction of Shell Structures

The design and construction of shell structures represent a pinnacle of engineering innovation, combining aesthetic appeal with structural integrity. These complex forms, often seen in iconic buildings and bridges, require meticulous planning and execution. At the heart of this process are three critical components: the selection of materials and their properties, the rigorous structural analysis and modeling, and the specialized construction techniques that overcome inherent challenges. **Materials and Their Properties** play a foundational role in shell structures. The choice of material—whether it be concrete, steel, or advanced composites—determines the strength, durability, and sustainability of the structure. Understanding the mechanical properties, such as tensile strength, compressive strength, and elasticity, is essential for ensuring that the shell can withstand various loads and environmental conditions. **Structural Analysis and Modeling** are crucial for predicting how these structures will behave under different scenarios. Advanced computational models and simulations help engineers optimize the design, minimizing material usage while maximizing structural efficiency. This phase involves intricate calculations to ensure that the shell can resist external forces without compromising its stability or safety. **Construction Techniques and Challenges** are equally important, as they translate the design into reality. Specialized methods such as formwork, prefabrication, and innovative assembly techniques are employed to achieve the desired shape and precision. However, these techniques also present unique challenges, including ensuring uniformity, managing logistics, and addressing potential defects. In this article, we will delve into these three essential aspects, starting with **Materials and Their Properties**, to provide a comprehensive understanding of how shell structures are designed and constructed. By examining the properties of materials, we set the stage for a deeper exploration of the entire process.

Materials and Their Properties

When designing and constructing shell structures, the selection of materials is crucial due to their significant impact on the structural integrity, durability, and aesthetic appeal of the final product. Shell structures, characterized by their thin, curved shapes that distribute loads efficiently across their surfaces, require materials with specific properties to ensure optimal performance. **Strength and Stiffness**: Materials such as steel, aluminum, and advanced composites like carbon fiber reinforced polymers (CFRP) are often chosen for their high strength-to-weight ratios. These materials provide the necessary stiffness to resist deformation under various loads while minimizing the overall weight of the structure. For instance, in the construction of large domes or arches, high-strength steel alloys can be used to achieve the desired structural rigidity without compromising on aesthetics. **Durability**: The durability of a shell structure is heavily dependent on the material's resistance to environmental factors such as corrosion, weathering, and fatigue. Concrete, for example, is a popular choice for many shell structures due to its durability and ability to withstand harsh environmental conditions. However, it may require additional protective coatings or treatments to enhance its resistance to chemical attacks and weathering. In contrast, materials like fiberglass and certain polymers offer inherent resistance to corrosion and can be particularly beneficial in marine or industrial environments. **Flexibility and Formability**: The ability of a material to be shaped into complex forms without losing its structural integrity is vital for shell structures. Materials like wood, particularly laminated veneer lumber (LVL), and advanced composites can be easily molded into curved shapes. These materials allow architects and engineers to create intricate designs that not only serve functional purposes but also add to the visual appeal of the structure. **Thermal and Acoustic Properties**: Depending on the intended use of the shell structure, materials with specific thermal and acoustic properties may be selected. For example, in buildings designed for energy efficiency, materials with low thermal conductivity such as insulating foams or aerated concrete can help regulate internal temperatures. Similarly, in auditoriums or concert halls, materials with favorable acoustic properties like wood or specialized acoustic panels can enhance sound quality. **Sustainability**: Increasingly, the choice of materials for shell structures is influenced by sustainability considerations. Materials such as bamboo, recycled metals, and sustainable wood products offer environmentally friendly alternatives without compromising on performance. These materials not only reduce the carbon footprint of the structure but also align with modern architectural trends that emphasize eco-friendliness. **Cost and Availability**: Finally, the cost and availability of materials play a significant role in the design and construction process. While advanced materials like CFRP offer superior performance, they can be prohibitively expensive for large-scale projects. In such cases, more conventional materials like steel or concrete may be preferred due to their lower costs and widespread availability. In summary, the selection of materials for shell structures is a multifaceted process that involves careful consideration of strength, durability, flexibility, thermal and acoustic properties, sustainability, and cost. By choosing materials that align with these criteria, engineers and architects can create shell structures that are not only structurally sound but also aesthetically pleasing and environmentally responsible.

Structural Analysis and Modeling

Structural analysis and modeling are crucial components in the design and construction of shell structures, ensuring these complex systems can withstand various loads and stresses while maintaining their integrity. Shell structures, characterized by their thin, curved shapes that distribute loads efficiently across their surfaces, require meticulous analysis to predict their behavior under different conditions. In structural analysis, engineers employ advanced mathematical models and computational tools to simulate the behavior of shell structures under various loads such as gravity, wind, seismic activity, and internal pressures. Finite Element Analysis (FEA) is a common method used to discretize the shell into smaller elements, allowing for detailed stress and strain calculations. This approach helps in identifying potential weak points and optimizing the design for maximum strength and minimal material usage. The modeling process involves creating detailed digital representations of the shell structure using Computer-Aided Design (CAD) software. These models are then subjected to various simulations to assess performance under different scenarios. For instance, dynamic analysis can predict how a shell structure will respond to dynamic loads like earthquakes or high winds, while static analysis evaluates its stability under constant loads. Material properties also play a significant role in structural analysis. Engineers must consider factors such as tensile strength, compressive strength, and elasticity to ensure that the chosen materials can handle the anticipated stresses without failure. Advanced materials like fiber-reinforced polymers (FRP) and high-strength concrete are often used in modern shell structures due to their superior mechanical properties. Moreover, structural analysis involves considering the interactions between the shell and its supporting systems. This includes evaluating the connections between the shell and its foundation or other structural elements to ensure that loads are transferred efficiently without causing undue stress concentrations. In addition to these technical aspects, sustainability and environmental impact are increasingly important considerations in modern structural analysis. Engineers aim to design shell structures that not only meet performance criteria but also minimize environmental footprint through efficient use of materials and energy. By integrating these elements—advanced modeling techniques, thorough material selection, comprehensive load analysis, and sustainable design practices—structural analysis ensures that shell structures are both aesthetically pleasing and functionally robust. This holistic approach is essential for the successful design and construction of shell structures that can safely serve their intended purposes over their lifespan. Ultimately, the precision and accuracy of structural analysis directly influence the safety, efficiency, and durability of shell structures. As technology continues to evolve with advancements in computational power and simulation tools, the field of structural analysis will remain a cornerstone in the development of innovative and resilient shell structures.

Construction Techniques and Challenges

The construction of shell structures, characterized by their curved and continuous surfaces, presents a unique set of techniques and challenges. From the outset, the design phase is crucial as it dictates the feasibility and efficiency of the construction process. Engineers often employ advanced computational tools to simulate various loads and stresses that the shell structure will endure, ensuring optimal material distribution and structural integrity. Once the design is finalized, the construction process typically begins with site preparation, which involves leveling the ground and laying a foundation that can support the weight and stresses of the shell. One of the primary techniques used in constructing shell structures is the use of formwork. This involves creating a mold or template into which concrete or other materials are poured to achieve the desired shape. For complex geometries, advanced formwork systems such as 3D-printed molds or inflatable forms may be employed. Another technique is the application of pre-stressed concrete, where cables or wires are tensioned before the concrete sets, enhancing the structure's strength and durability. However, several challenges arise during the construction of shell structures. One significant issue is ensuring accurate alignment and curvature of the formwork to maintain the intended shape. This requires precise engineering and careful execution to avoid deviations that could compromise the structure's integrity. Additionally, working with curved surfaces often necessitates specialized labor and equipment, increasing costs and potentially extending project timelines. Material selection also poses a challenge. Shell structures often require materials with high tensile strength and flexibility to withstand various environmental conditions. While concrete remains a popular choice due to its durability and cost-effectiveness, it may not always be suitable for every application. Alternative materials like fiber-reinforced polymers (FRP) or advanced composites offer superior strength-to-weight ratios but come with higher costs and specific handling requirements. Another critical aspect is ensuring structural stability during the construction phase. Shell structures can be vulnerable to wind loads and other external forces before they are fully completed. Temporary bracing systems or scaffolding may be necessary to provide additional support until the structure gains sufficient strength. Safety is another paramount concern in the construction of shell structures. Workers must navigate complex geometries and potentially hazardous conditions, such as working at heights or in confined spaces. Implementing rigorous safety protocols and training programs is essential to mitigate these risks. Innovative technologies are increasingly being integrated into the construction process to address these challenges. For instance, Building Information Modeling (BIM) allows for detailed digital models that can predict potential issues before they arise on-site. Additionally, drones equipped with sensors can monitor progress and detect any deviations from the planned design in real-time. In conclusion, constructing shell structures demands a blend of advanced engineering techniques, precise execution, and careful consideration of various challenges. By leveraging cutting-edge technologies and adhering to stringent safety standards, builders can successfully overcome these hurdles to create structures that are not only aesthetically striking but also robust and durable. The successful execution of these techniques underscores the importance of meticulous planning and innovative problem-solving in bringing these complex designs to life.

Applications and Examples of Shell Structures

Shell structures, characterized by their thin, curved forms, have been a cornerstone of engineering and architecture for centuries. These structures leverage minimal material to achieve maximum strength and aesthetic appeal, making them versatile across various applications. In the realm of architecture, shell structures are particularly renowned for their use in domes, vaults, and roofs, where they provide both functional support and visual grandeur. Beyond architectural uses, shell structures also play a critical role in engineering applications such as bridges, tanks, and dams, where their ability to distribute loads efficiently is paramount. Additionally, modern innovations are pushing the boundaries of what shell structures can achieve, incorporating advanced materials and computational design techniques to create even more complex and efficient forms. As we delve into the applications and examples of shell structures, we will first explore their architectural uses, starting with the iconic and enduring presence of domes, vaults, and roofs.

Architectural Uses: Domes, Vaults, and Roofs

In the realm of architectural engineering, domes, vaults, and roofs are quintessential elements that not only provide structural integrity but also elevate the aesthetic and functional aspects of buildings. These shell structures, characterized by their curved or arched forms, have been integral to various architectural styles across history and cultures. **Domes**, for instance, are spherical or hemispherical structures that distribute loads evenly across their surface, making them incredibly resilient. The Pantheon in Rome, with its imposing dome dating back to 126 AD, is a testament to the enduring legacy of this design. Domes are often used in grand public buildings such as mosques, cathedrals, and government buildings due to their ability to create expansive, unobstructed interior spaces. **Vaults**, another type of shell structure, consist of a series of arches that form a continuous surface. They are commonly used in ceilings and roofs to span large areas without the need for intermediate supports. Gothic cathedrals like Notre-Dame de Paris exemplify the use of vaults, where ribbed vaults allow for taller ceilings and larger windows, enhancing both structural stability and visual grandeur. Vaults can also be found in modern architecture, such as in the design of underground parking garages and subway tunnels, where they provide robust support against soil pressure. **Roofs**, while often considered a more mundane aspect of architecture compared to domes and vaults, play a crucial role in protecting buildings from environmental elements. Shell roofs, specifically those with hyperbolic paraboloid shapes (hypar roofs), offer unique advantages. These roofs can be constructed using thin materials yet maintain significant strength due to their curved geometry. The Sydney Opera House in Australia features iconic hypar roofs that not only provide structural efficiency but also contribute to the building's striking visual identity. Additionally, shell roofs are used in sports stadiums and exhibition halls where large, open spaces are required without the obstruction of columns. The versatility of domes, vaults, and roofs extends beyond their structural benefits; they also offer significant aesthetic appeal. These shell structures can be designed to incorporate various materials and finishes, from traditional stone and brick to modern glass and steel. For example, the Guggenheim Museum in Bilbao, Spain, features a flowing glass atrium that combines both functional and artistic elements. This blend of form and function makes these structures not just essential components of buildings but also symbols of architectural innovation. In contemporary architecture, the application of domes, vaults, and roofs continues to evolve with advancements in materials science and computational design. Modern techniques allow for the creation of complex geometries that were previously impossible to achieve. This has led to the development of innovative structures such as geodesic domes and free-form roofs that push the boundaries of what is architecturally possible. The use of computer-aided design (CAD) software enables architects to simulate various loads and stresses on these structures, ensuring optimal performance while maintaining their artistic integrity. In conclusion, domes, vaults, and roofs are fundamental elements in architectural design that have been refined over centuries. Their ability to combine structural strength with aesthetic appeal makes them indispensable in a wide range of building types. From ancient monuments to modern marvels, these shell structures continue to inspire architects and engineers alike, showcasing the perfect blend of artistry and engineering prowess.

Engineering Applications: Bridges, Tanks, and Dams

Engineering applications of shell structures are diverse and critical, particularly in the construction of bridges, tanks, and dams. These structures leverage the inherent strength and efficiency of shells to support heavy loads while minimizing material usage. In bridge construction, shell structures are often used for arch bridges or bridge decks due to their ability to distribute loads evenly across the surface. For instance, the iconic Gateway Arch in St. Louis, Missouri, is a prime example of a shell structure in bridge design, where its parabolic shape provides both aesthetic appeal and structural integrity. Similarly, in the realm of water storage and management, tanks and reservoirs frequently employ shell designs to maximize volume while maintaining structural stability. These tanks can be spherical or cylindrical in shape, allowing them to withstand internal pressures efficiently. Dams, another crucial application area for shell structures, benefit from their ability to resist external forces such as water pressure and seismic activity. The design of dams often incorporates shell elements like arch dams or dome-shaped structures that can distribute stress uniformly across the surface. The Hoover Dam, for example, features an arch-gravity design that combines the strength of both arch and gravity dams, utilizing shell principles to ensure stability and durability. These engineering applications highlight the versatility and effectiveness of shell structures in handling complex loads and stresses, making them indispensable in modern civil engineering projects. Moreover, the use of shell structures in these applications is not just about functionality but also about sustainability and cost-efficiency. By optimizing the shape and material distribution, engineers can achieve significant reductions in material usage without compromising on strength or performance. This not only lowers construction costs but also minimizes environmental impact by reducing the amount of resources required. Additionally, advanced computational tools and simulation techniques have enabled engineers to design and analyze shell structures with unprecedented precision, allowing for even more innovative and efficient designs. In summary, the engineering applications of shell structures in bridges, tanks, and dams exemplify their critical role in modern infrastructure development. These structures showcase how the unique properties of shells can be harnessed to create robust, efficient, and sustainable solutions that meet the demands of contemporary engineering challenges. As technology continues to evolve, it is likely that shell structures will remain a cornerstone of innovative engineering practices, driving advancements in various fields and ensuring the reliability and longevity of our built environment.

Modern Innovations and Future Trends

Modern innovations in shell structures are revolutionizing various fields, from architecture and engineering to aerospace and biomedical applications. One of the most significant advancements is the integration of advanced materials such as carbon fiber reinforced polymers (CFRP) and smart materials. These materials offer exceptional strength-to-weight ratios, enabling the construction of lighter yet more durable shell structures. For instance, in aerospace engineering, CFRP shells are used in aircraft and spacecraft to reduce weight while maintaining structural integrity, thereby enhancing fuel efficiency and performance. Another trend is the use of computational design and 3D printing technologies. These tools allow for the creation of complex geometries that were previously impossible to manufacture. Architects and engineers can now design intricate shell structures with optimized shapes that maximize structural efficiency and aesthetic appeal. For example, the use of parametric design has led to the development of innovative buildings like the Sydney Opera House, where complex shell roofs provide both functional and artistic value. Sustainability is also a key driver in modern shell structure innovations. Green building practices are increasingly incorporating shell structures made from sustainable materials such as bamboo and recycled plastics. These eco-friendly shells not only reduce environmental impact but also offer unique thermal insulation properties, contributing to energy-efficient buildings. In addition, advancements in sensor technology and IoT integration are transforming shell structures into smart, responsive systems. Embedded sensors can monitor stress levels, temperature changes, and other environmental factors in real-time, allowing for predictive maintenance and enhanced safety. This is particularly crucial in critical infrastructure like bridges and tunnels, where early detection of potential issues can prevent catastrophic failures. Looking ahead, future trends in shell structures will likely involve even more sophisticated applications of nanotechnology and biotechnology. Researchers are exploring the use of nanomaterials to create ultra-strong yet flexible shells that could be used in biomedical devices such as implantable prosthetics or drug delivery systems. Moreover, biomimetic designs inspired by nature—such as the shell of an abalone or the structure of a leaf—promise to deliver novel solutions with improved mechanical properties and sustainability. The integration of artificial intelligence (AI) and machine learning algorithms will also play a pivotal role in optimizing shell structure design and performance. AI can analyze vast datasets to predict optimal shapes and materials for specific applications, ensuring that future shell structures are not only aesthetically pleasing but also highly efficient and resilient. In conclusion, modern innovations in shell structures are pushing the boundaries of what is possible across multiple disciplines. From advanced materials and computational design to sustainable practices and smart technologies, these advancements are setting the stage for a future where shell structures become even more integral to our daily lives—whether in the buildings we inhabit, the vehicles we travel in, or the medical devices that improve our health. As technology continues to evolve, we can expect shell structures to become increasingly sophisticated, efficient, and sustainable.