What Is Rod Knock

Rod knock, a critical engine issue, can significantly impact the performance and longevity of your vehicle. It is essential to understand this problem to prevent severe damage and costly repairs. This article delves into the intricacies of rod knock, starting with its definition and underlying causes. We will explore what rod knock is, how it occurs, and the factors that contribute to its development. Following this foundational understanding, we will discuss the symptoms and signs that indicate the presence of rod knock, helping you identify potential issues early. Finally, we will outline the steps for diagnosing and addressing rod knock, providing practical solutions to mitigate or resolve the problem. By grasping these key aspects, you will be better equipped to maintain your vehicle's health and avoid the consequences of neglected engine issues. Let's begin by understanding rod knock: its definition and causes.

Understanding Rod Knock: Definition and Causes

Understanding rod knock is crucial for any car enthusiast or mechanic, as it can indicate serious engine issues that require immediate attention. Rod knock, also known as lifter noise or engine knock, is a distinct sound that signals potential damage to your vehicle's engine. To grasp this concept fully, it's essential to delve into three key areas: the definition of rod knock, the common causes behind it, and the engine components involved. **What is Rod Knock?** provides a foundational understanding of this phenomenon, explaining the mechanical processes that lead to the characteristic knocking sound. **Common Causes of Rod Knock** explores the various factors that contribute to this problem, such as worn-out bearings, low oil levels, and improper engine tuning. Finally, **Engine Components Involved** details the specific parts affected by rod knock, including connecting rods, crankshafts, and piston assemblies. By understanding these aspects, you can better diagnose and address rod knock before it leads to costly repairs or even engine failure. Let's start by examining **What is Rod Knock?** to gain a comprehensive insight into this critical engine issue.

What is Rod Knock?

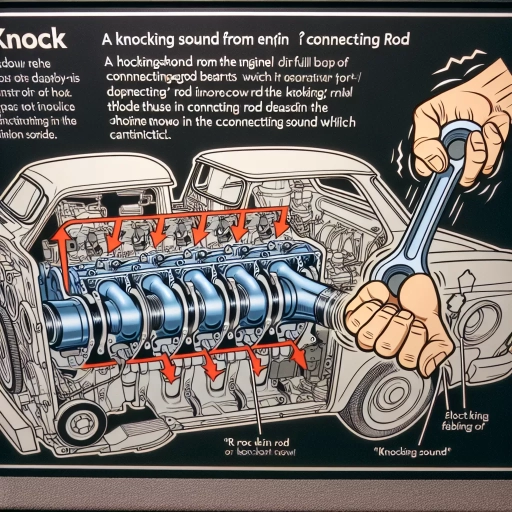

Rod knock, also known as lifter tick or lifter noise, is a mechanical issue within an internal combustion engine that manifests as a distinct knocking or tapping sound. This noise is typically heard when the engine is cold and may diminish or disappear as the engine warms up. The primary cause of rod knock is wear and tear on the engine's connecting rods, which link the pistons to the crankshaft. Over time, these rods can become worn out due to factors such as high mileage, poor engine maintenance, or the use of low-quality engine oil. When this wear occurs, it can lead to increased clearance between the connecting rod bearings and the crankshaft, resulting in the characteristic knocking sound as the engine operates. Another common cause of rod knock is low oil pressure, which can prevent adequate lubrication of the engine's moving parts. Without sufficient lubrication, friction increases, leading to premature wear on components like the connecting rods and bearings. Additionally, using the wrong type of engine oil or failing to change it regularly can exacerbate this issue. In some cases, rod knock can also be caused by improper installation of engine components or manufacturing defects. It is crucial to address rod knock promptly because it can lead to more severe engine damage if left unchecked. Ignoring this problem can result in costly repairs down the line, including potential engine failure. Early detection and diagnosis are key; if you notice a persistent knocking sound from your engine, it is advisable to consult a mechanic for a thorough inspection and necessary repairs. Regular maintenance practices such as timely oil changes and inspections can help prevent rod knock from occurring in the first place. In summary, rod knock is a significant engine issue characterized by a knocking sound due to worn-out connecting rods or inadequate lubrication. It is essential to understand its causes and take proactive steps to maintain your vehicle's engine health to avoid more serious problems. By recognizing the signs of rod knock early and addressing them promptly, you can ensure your engine runs smoothly and efficiently for years to come.

Common Causes of Rod Knock

Rod knock, a concerning engine issue characterized by a knocking or clunking sound emanating from the engine, is often indicative of serious mechanical problems. Several common causes contribute to this phenomenon, each highlighting the importance of timely maintenance and inspection. One primary cause is **worn or damaged connecting rods**, which can result from excessive wear over time, poor lubrication, or high mileage. When these rods become worn, they can move more freely within their bearings, causing the distinctive knocking noise. Another significant factor is **low engine oil levels or poor oil quality**, as insufficient lubrication can lead to increased friction between moving parts, exacerbating wear and tear on the connecting rods and bearings. **Incorrect engine oil viscosity** can also play a role; using oil that is too thin or too thick for the engine's specifications can compromise its ability to properly lubricate the engine's components. Additionally, **engine overheating** can cause the metal components to expand and contract unevenly, leading to misalignment and increased stress on the connecting rods. **Piston slap**, where the piston moves slightly within its cylinder due to wear or improper fit, can also produce a similar knocking sound. Furthermore, **bearing failure**, whether due to wear, contamination, or improper installation, can disrupt the smooth operation of the engine's crankshaft and connecting rods, resulting in rod knock. Lastly, **engine block or crankshaft issues**, such as cracks or warping, can alter the alignment and movement of the connecting rods, leading to this problematic noise. Understanding these causes is crucial for diagnosing and addressing rod knock effectively, preventing further damage and ensuring the longevity of the engine.

Engine Components Involved

When discussing rod knock, it is crucial to understand the engine components involved in this phenomenon. Rod knock, also known as lifter noise or tapping, is a condition where the connecting rods in an engine begin to make a knocking or tapping sound due to improper clearance or wear. The primary components implicated in rod knock include the connecting rods, pistons, crankshaft, and bearings. **Connecting Rods**: These rods connect the pistons to the crankshaft, converting the up-and-down motion of the pistons into rotational energy. If the connecting rods are worn or if there is excessive clearance between the rod and its bearing, it can cause the rod to move slightly out of alignment, resulting in the knocking sound. **Pistons**: The pistons move up and down in the cylinders, driven by the explosive force of combustion. If a piston is not fitting properly in its cylinder or if it has become worn, it can affect the alignment and movement of the connecting rod, contributing to rod knock. **Crankshaft**: This is the main shaft that converts the reciprocating motion of the pistons into rotational energy. Wear on the crankshaft journals (where the bearings ride) can lead to increased clearance and misalignment, causing the connecting rods to knock. **Bearings**: Engine bearings support the crankshaft and connecting rods, allowing them to move smoothly. Worn-out bearings can increase the clearance between these components, leading to the characteristic knocking sound of rod knock. In addition to these components, other factors such as low oil pressure, dirty or degraded engine oil, and overheating can also contribute to rod knock by exacerbating wear and tear on these critical parts. Understanding how these components interact and how their condition affects engine performance is essential for diagnosing and addressing rod knock effectively. By recognizing the roles of connecting rods, pistons, crankshaft, and bearings in this issue, mechanics can take targeted steps to repair or replace damaged parts and restore smooth engine operation.

Identifying Rod Knock: Symptoms and Signs

Identifying rod knock, a critical issue in engine health, requires a keen eye and ear for several key symptoms and signs. This article delves into the three primary indicators of rod knock: audible noises and vibrations, performance issues and warning signs, and visual indicators. Each of these categories provides crucial clues that can help diagnose and address the problem before it leads to more severe engine damage. Audible noises and vibrations are often the first signs that something is amiss, as they can manifest as distinct knocking or clunking sounds emanating from the engine. Performance issues and warning signs may include decreased engine power, increased oil consumption, and dashboard warning lights. Finally, visual indicators such as oil leaks or excessive smoke can also signal rod knock. By understanding these symptoms, car owners and mechanics can take prompt action to prevent further damage. Let's start by examining the most immediate and noticeable signs: audible noises and vibrations.

Audible Noises and Vibrations

When diagnosing engine issues, understanding audible noises and vibrations is crucial, especially in identifying rod knock. Rod knock, also known as rod bearing knock, is a specific type of engine noise that indicates wear or failure of the connecting rod bearings. Here’s how to distinguish it from other sounds: **Audible Noises:** - **Rod Knock:** Characterized by a deep, metallic clunking or knocking sound that occurs when the engine is under load. This noise is often most pronounced when accelerating or decelerating. - **Piston Slap:** A slapping or tapping noise usually heard when the engine is cold and often diminishes as the engine warms up. - **Lifter Noise:** A tapping or clicking sound that can be heard at the top of the engine and may be more noticeable when the engine is cold. - **Main Bearing Noise:** Similar to rod knock but typically lower in pitch and more consistent in timing. **Vibrations:** - **Engine Vibration:** Rod knock can cause noticeable vibrations that resonate through the vehicle, particularly when the knocking sound is present. - **Balance Shaft Issues:** These can cause vibrations that are more pronounced at certain engine speeds. - **Accessory Belt Issues:** Misaligned or worn-out belts can cause vibrations but are usually accompanied by other symptoms like squealing noises. **Key Differences:** - **Timing:** Rod knock is typically heard during specific engine operations like acceleration or deceleration, whereas other noises may be constant or vary with engine speed. - **Pitch and Volume:** The deep clunking sound of rod knock is distinct from higher-pitched noises like lifter tap or piston slap. - **Location:** The source of the noise can help identify the issue; rod knock originates from the lower part of the engine block, while lifter noise comes from the top. **Diagnostic Steps:** 1. **Listen Carefully:** Pay attention to when and how the noise occurs. Rod knock is usually loudest when the engine is under load. 2. **Use a Stethoscope:** This can help pinpoint the exact location of the noise within the engine. 3. **Check Oil Pressure:** Low oil pressure can exacerbate rod bearing wear, leading to knock. 4. **Monitor Engine Performance:** Look for signs of decreased performance, such as reduced power output or increased fuel consumption. By carefully analyzing these audible noises and vibrations, you can more accurately identify whether your engine is experiencing rod knock or another issue. This precise diagnosis is essential for timely and effective repairs to prevent further damage to your engine.

Performance Issues and Warning Signs

Performance issues in an engine can often be indicative of more serious problems, such as rod knock, which is a condition where the connecting rods in the engine begin to wear out or fail. Identifying these performance issues early on is crucial for preventing further damage and ensuring the longevity of the engine. Here are some key warning signs to look out for: 1. **Unusual Noises**: One of the most common indicators of performance issues is unusual engine noise. Rod knock typically manifests as a loud, metallic clattering or knocking sound that becomes more pronounced when the engine is under load or at higher RPMs. Other noises like grinding, whining, or hissing can also signal other types of engine problems. 2. **Vibration**: Excessive vibration while driving or when the engine is idling can be a sign that something is amiss. This vibration could be felt through the steering wheel, seat, or even the entire vehicle, indicating imbalance or misalignment within the engine. 3. **Oil Consumption**: Increased oil consumption is another red flag. If your vehicle is using more oil than usual, it could indicate worn piston rings or cylinder walls, which are often precursors to more severe issues like rod knock. 4. **Decreased Performance**: A noticeable decrease in engine performance, such as reduced power output, slower acceleration, or difficulty maintaining speed on inclines, can signal internal engine problems. 5. **Check Engine Light**: Modern vehicles are equipped with sophisticated diagnostic systems that can detect anomalies in engine performance. If your check engine light comes on and stays on, it's essential to have it checked by a mechanic as soon as possible. 6. **Smoke from the Exhaust**: Blue smoke from the exhaust typically indicates that oil is leaking into the combustion chamber and being burned along with fuel. This can be a sign of worn piston rings or other internal components that may lead to rod knock if not addressed. 7. **Overheating Engine**: An overheating engine can cause significant damage to internal components, including connecting rods. If your temperature gauge is consistently higher than normal or if you notice steam coming from the hood, it's critical to stop driving and have your vehicle checked immediately. 8. **Low Compression**: Low compression in one or more cylinders can indicate that there is a problem with the piston rings or valves, which could eventually lead to rod knock if left unchecked. By recognizing these warning signs early, you can take proactive steps to diagnose and repair any issues before they escalate into more severe problems like rod knock. Regular maintenance checks and prompt action when these symptoms appear can help extend the life of your engine and prevent costly repairs down the line.

Visual Indicators of Rod Knock

Visual indicators of rod knock are crucial for diagnosing this engine issue, as they often precede audible symptoms and can help in early detection. One of the primary visual signs is **Oil Consumption and Leaks**. If your engine is experiencing rod knock, it may consume more oil than usual due to increased wear on the piston rings and cylinder walls. Look for signs of oil leaks around the engine, particularly around the crankcase and cylinder head areas. Another indicator is **Excessive Smoke** from the exhaust pipe, which can be a result of oil entering the combustion chamber and burning along with fuel. **Dashboard Warning Lights** can also be a visual cue. Modern vehicles often have sophisticated engine management systems that can detect anomalies in engine performance, including rod knock. If your dashboard lights up with the "Check Engine" or "Service Engine Soon" light, it could be a sign that your engine is experiencing internal issues such as rod knock. **Vibration** is another key visual indicator, although it may also be felt. If your vehicle's engine is vibrating more than usual, especially when idling or under load, it could be a sign of rod knock. This vibration can sometimes be observed through the hood or even felt through the steering wheel or seat. **Performance Issues** can also manifest visually. If your vehicle's performance is declining—such as reduced power output, poor acceleration, or difficulty maintaining speed—it could be indicative of rod knock affecting the engine's efficiency. Additionally, **Coolant Temperature** fluctuations can be a visual sign. Rod knock can lead to increased friction within the engine, causing it to run hotter than normal. Keep an eye on your coolant temperature gauge; if it consistently runs higher than usual, it may indicate internal engine problems. Lastly, **Engine Mount Movement** can sometimes be observed. If the engine mounts are worn out or if there is significant internal engine movement due to rod knock, you might notice the engine block moving more than usual when the engine is running. By paying attention to these visual indicators, you can identify potential rod knock issues early on and take corrective action before they escalate into more serious problems. Early detection is key to preventing further damage and ensuring the longevity of your vehicle's engine.

Diagnosing and Addressing Rod Knock: Steps and Solutions

Diagnosing and addressing rod knock is a critical process for maintaining the health and longevity of an engine. Rod knock, a condition characterized by the knocking or clunking sound of the connecting rods, can lead to severe engine damage if left untreated. To effectively manage this issue, it is essential to employ a multi-faceted approach. First, **Diagnostic Techniques for Rod Knock** must be utilized to accurately identify the problem. This involves using tools such as stethoscopes, sound level meters, and advanced diagnostic software to pinpoint the source of the noise. Once diagnosed, **Repair and Replacement Options** can be explored to rectify the issue, which may include replacing worn-out components or performing more extensive engine overhauls. Additionally, **Preventive Measures to Avoid Rod Knock** should be implemented to prevent future occurrences, such as regular oil changes and maintaining proper engine lubrication. By understanding these steps and solutions, vehicle owners and mechanics can ensure that engines run smoothly and efficiently. Let's begin by delving into the **Diagnostic Techniques for Rod Knock**, which form the foundation of any successful treatment plan.

Diagnostic Techniques for Rod Knock

When diagnosing rod knock, several diagnostic techniques are employed to accurately identify and assess the condition. **Visual Inspection** is a preliminary step where the engine is visually examined for any signs of oil leaks, excessive wear on moving parts, or other visible damage. **Oil Analysis** involves checking the engine oil for metal shavings or debris, which can indicate internal engine wear. **Sound Analysis** is crucial; rod knock typically produces a distinct knocking or clunking sound that is most audible when the engine is cold and under load. Mechanics often use **Stethoscopes** or **Mechanical Stethoscopes** to pinpoint the source of the noise by listening directly to different parts of the engine. **Compression Testing** can help determine if there is a loss of compression in any cylinder, which might be related to rod knock. **Leak-Down Testing** further identifies where the leak is occurring within the engine. **Endoscope Inspection** allows for a visual examination of internal engine components without disassembling the engine, providing valuable insights into the condition of rods and bearings. **Vibration Analysis** using specialized equipment can detect abnormal vibrations that may indicate rod knock. **Dynamometer Testing** can be used to measure engine performance under various loads, helping to isolate performance issues that might be related to rod knock. In some cases, **Engine Disassembly** may be necessary for a thorough inspection and diagnosis. Advanced diagnostic tools like **OBD-II Scanners** can also provide data on engine performance and any trouble codes that might be related to internal engine issues. Each of these techniques provides valuable information that, when combined, helps in making an accurate diagnosis of rod knock. By systematically applying these methods, mechanics can determine the extent of the problem and recommend appropriate repairs or replacements to address the issue effectively.

Repair and Replacement Options

When diagnosing and addressing rod knock, one of the critical steps involves evaluating repair and replacement options. If the diagnosis confirms that the engine is experiencing rod knock, it is essential to act promptly to prevent further damage. Here are the key considerations: 1. **Assessing the Extent of Damage**: Before deciding on a course of action, a thorough inspection is necessary to determine the extent of the damage. This includes checking for any signs of wear on the connecting rods, bearings, and crankshaft. 2. **Repair Options**: - **Rebuilding the Engine**: If the damage is limited, rebuilding the engine might be a viable option. This involves replacing worn-out components such as bearings and possibly resurfacing or replacing the crankshaft. - **Replacing Connecting Rods**: If only the connecting rods are damaged, replacing them with new ones can be a cost-effective solution. - **Bearing Replacement**: Replacing worn-out bearings with new ones can also resolve the issue if the damage is confined to these components. 3. **Replacement Options**: - **Engine Replacement**: In severe cases where extensive damage has occurred, replacing the entire engine may be the most practical solution. This could involve installing a new engine or a remanufactured one. - **Crankshaft Replacement**: If the crankshaft is severely damaged, it may need to be replaced entirely to ensure proper engine function. 4. **Cost Considerations**: The cost of repairs versus replacement must be carefully evaluated. While rebuilding or repairing individual components can be less expensive upfront, it may not always be the most cost-effective long-term solution if further issues arise. 5. **Labor and Expertise**: It is crucial to have a qualified mechanic perform these repairs to ensure that the work is done correctly and safely. Amateur attempts at engine repair can lead to more severe problems and increased costs. 6. **Preventative Measures**: After addressing the rod knock issue, it is important to implement preventative measures such as regular oil changes, monitoring engine performance, and addressing any potential issues promptly to avoid future occurrences. In summary, addressing rod knock requires a careful assessment of the damage followed by a decision on whether to repair or replace affected components. Each option has its own set of considerations regarding cost, labor, and long-term reliability. By choosing the right approach based on the extent of the damage and consulting with a qualified mechanic, you can ensure that your engine operates smoothly and efficiently.

Preventive Measures to Avoid Rod Knock

To prevent rod knock, several proactive measures can be taken to ensure the longevity and health of your engine. **Regular Oil Changes** are crucial as they help maintain the lubrication of moving parts, reducing friction and wear on the connecting rods. Use high-quality oil that meets the manufacturer's specifications, and change it at the recommended intervals. **Proper Engine Maintenance** involves checking and replacing worn-out components such as piston rings, cylinder liners, and bearings before they cause significant damage. Regularly inspecting the engine for signs of wear or overheating can also help in early detection of potential issues. **Monitoring Engine Oil Pressure** is another key preventive measure. Low oil pressure can lead to inadequate lubrication, which is a common cause of rod knock. Ensure that your oil pressure gauge is functioning correctly and address any discrepancies promptly. **Avoiding Extreme Temperatures** is also important; both overheating and extreme cold can stress engine components, leading to premature wear. **Driving Habits** play a significant role in preventing rod knock. Avoid sudden acceleration or deceleration, as these can put undue stress on the engine's internal components. Additionally, **Avoiding Overloading** your vehicle can help prevent excessive strain on the engine. **Using the Right Fuel** is essential; using fuel with the correct octane rating for your vehicle helps maintain optimal engine performance and reduces the risk of engine knock. **Regular Tune-Ups**, including spark plug replacements and fuel injector cleaning, can also help maintain engine efficiency and reduce the likelihood of rod knock. Finally, **Addressing Issues Promptly** is vital. If you notice any unusual noises or vibrations from your engine, do not ignore them. Early intervention can prevent minor issues from escalating into major problems like rod knock. By following these preventive measures, you can significantly reduce the risk of rod knock and ensure your engine runs smoothly for years to come.