What Is Composite Decking Made Of

Composite decking has revolutionized the way we build and maintain outdoor living spaces, offering a durable, low-maintenance alternative to traditional wood decking. But what exactly is composite decking made of? To understand its appeal, it's essential to delve into the materials used in its construction, the manufacturing process that brings these components together, and the benefits and characteristics that make it a preferred choice for homeowners and builders alike. This article will explore these key aspects, starting with the materials that form the foundation of composite decking. By examining the specific components and how they are combined, we can better appreciate the robustness and versatility of this modern building material. Let's begin by looking at the materials used in composite decking, which sets the stage for understanding its entire lifecycle and advantages. --- **Materials Used in Composite Decking**

Materials Used in Composite Decking

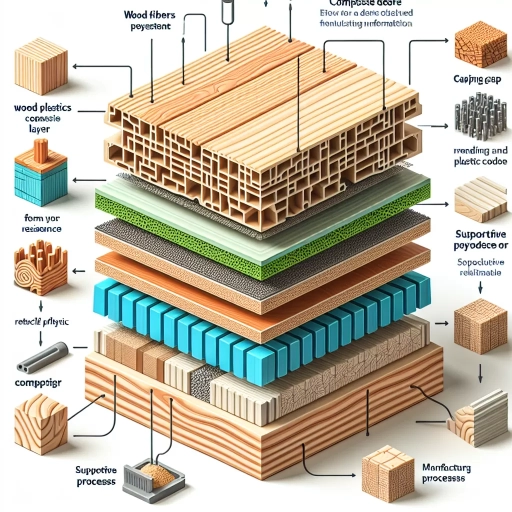

Composite decking has revolutionized the way we construct outdoor living spaces, offering a durable, low-maintenance alternative to traditional wood decking. At the heart of this innovation are three key components: recycled plastics, natural fibers, and additives and fillers. These materials work in harmony to create a product that is not only environmentally friendly but also aesthetically pleasing and highly functional. Recycled plastics, for instance, provide the structural integrity and resistance to rot and insect damage that composite decking is known for. Natural fibers add a touch of organic beauty and help in achieving a wood-like appearance without the drawbacks of natural wood. Finally, additives and fillers enhance the performance and longevity of the decking by improving its UV resistance, color stability, and overall durability. By understanding the role of each of these components, homeowners and builders can make informed decisions about their decking choices. Let's start by exploring the critical role of recycled plastics in composite decking.

1. Recycled Plastics

**Recycled Plastics** In the realm of composite decking, one of the most significant and environmentally conscious components is recycled plastics. These materials are derived from post-consumer waste, such as plastic bottles, containers, and other disposable items that would otherwise end up in landfills or oceans. The process of recycling these plastics involves collecting, sorting, cleaning, and then breaking them down into smaller pieces known as "flakes" or "pellets." These pellets are then melted and reformed into various shapes and forms suitable for use in composite decking. The integration of recycled plastics into composite decking offers several compelling advantages. Firstly, it significantly reduces the amount of waste sent to landfills, contributing to a more sustainable future. By reusing materials that would otherwise be discarded, composite decking manufacturers help conserve natural resources and decrease the environmental footprint associated with extracting and processing raw materials. Additionally, recycled plastics provide a durable and long-lasting alternative to traditional wood decking. They are resistant to rot, mold, and insect damage, which means homeowners can enjoy their decks for years without the need for frequent maintenance or replacements. From a performance perspective, recycled plastics in composite decking also offer superior resistance to weathering. Unlike natural wood, which can warp, crack, or fade under exposure to sunlight and moisture, recycled plastics maintain their integrity and appearance over time. This makes them an ideal choice for outdoor applications where durability and low maintenance are key considerations. Furthermore, many manufacturers blend recycled plastics with other materials like wood fibers or bamboo, creating a composite that combines the best attributes of each component. This blend enhances the overall strength, stability, and aesthetic appeal of the decking material. The use of recycled plastics in composite decking also aligns with growing consumer demand for eco-friendly products. Homeowners increasingly seek out sustainable options that not only enhance their living spaces but also contribute positively to the environment. By choosing composite decking made with recycled plastics, individuals can feel confident that their purchase supports responsible waste management and resource conservation. Moreover, many manufacturers of composite decking materials are now obtaining certifications from organizations such as the International Organization for Standardization (ISO) and the Forest Stewardship Council (FSC), further validating their commitment to sustainability. In conclusion, the incorporation of recycled plastics into composite decking represents a significant step forward in sustainable building practices. It offers a practical solution to the global issue of plastic waste while providing homeowners with a durable, low-maintenance, and aesthetically pleasing decking option. As technology continues to evolve and consumer awareness grows, the role of recycled plastics in composite decking is likely to become even more prominent, driving innovation and environmental stewardship in the construction industry.

2. Natural Fibers

Natural fibers are a significant component in the production of composite decking, offering a blend of sustainability, durability, and aesthetic appeal. These fibers, derived from plants such as wood, bamboo, hemp, and flax, are integrated into composite materials to enhance their performance and environmental footprint. Unlike synthetic fibers, natural fibers provide a more organic look and feel to the decking, making them a preferred choice for homeowners seeking a natural appearance without the high maintenance associated with traditional wood decks. The use of natural fibers in composite decking begins with their extraction and processing. Wood fibers, for instance, are often sourced from recycled wood products or sustainably managed forests. These fibers are then cleaned, ground into fine particles, and mixed with polymer resins to form a composite material. This blend combines the strength and resistance of plastics with the natural beauty of wood, resulting in a durable and low-maintenance product. One of the key advantages of natural fibers in composite decking is their ability to mimic the appearance of real wood while offering superior resistance to rot, mold, and insect damage. This makes them ideal for outdoor applications where exposure to moisture and extreme weather conditions is common. Additionally, natural fibers contribute to the thermal stability of the composite material, reducing the likelihood of warping or cracking under temperature fluctuations. From an environmental perspective, natural fibers are a more sustainable option compared to synthetic alternatives. They are biodegradable and can be sourced from renewable resources, reducing the reliance on non-renewable materials and minimizing the carbon footprint of the decking. Furthermore, many manufacturers incorporate recycled materials into their composite products, further enhancing their eco-friendly credentials. In terms of performance, natural fibers also play a crucial role in improving the mechanical properties of composite decking. For example, wood fibers can enhance the tensile strength and impact resistance of the material, making it more resilient to heavy foot traffic and harsh weather conditions. This ensures that the decking remains stable and secure over its lifespan, requiring minimal upkeep beyond occasional cleaning. In conclusion, natural fibers are a vital component in the creation of composite decking, offering a unique combination of sustainability, durability, and aesthetic appeal. By leveraging these fibers, manufacturers can produce high-quality decking materials that not only perform well but also contribute to a more environmentally conscious construction practice. As consumers increasingly prioritize eco-friendly products, the use of natural fibers in composite decking is likely to continue growing, providing a compelling alternative to traditional decking materials.

3. Additives and Fillers

In the realm of composite decking, additives and fillers play a crucial role in enhancing the performance, durability, and aesthetic appeal of the final product. These components are meticulously selected to complement the primary materials—typically a blend of wood fibers and plastic resins—ensuring that composite decking meets the stringent demands of outdoor environments. Additives, such as UV stabilizers, are incorporated to protect the decking from the harsh effects of sunlight, preventing discoloration and degradation over time. These stabilizers absorb or block UV radiation, maintaining the color integrity and structural integrity of the decking. Additionally, mold and mildew inhibitors are added to prevent the growth of fungi and bacteria, which can compromise both the appearance and longevity of the decking. Fillers, on the other hand, serve multiple purposes. They can include materials like calcium carbonate or talc, which help in reducing the cost of production by replacing some of the more expensive resin content without compromising on performance. These fillers also contribute to improving the mechanical properties of the composite material by enhancing its stiffness and impact resistance. Furthermore, fillers can aid in improving the thermal stability of the composite, making it less prone to warping or deformation under varying temperature conditions. Another significant benefit of fillers is their ability to reduce shrinkage during the manufacturing process, ensuring that the final product maintains its dimensional stability. The combination of additives and fillers not only enhances the functional attributes but also contributes to the environmental sustainability of composite decking. By utilizing recycled materials in some fillers, manufacturers can reduce waste and minimize their ecological footprint. For instance, recycled plastics can be used as part of the filler content, thereby reducing landfill waste and conserving natural resources. This approach aligns with the growing consumer preference for eco-friendly products that offer both performance and sustainability. In summary, additives and fillers are essential components in composite decking that significantly impact its overall quality and functionality. They ensure that the decking remains resistant to environmental stresses while maintaining its aesthetic appeal over an extended period. By carefully selecting these additives and fillers, manufacturers can produce composite decking that is not only durable but also environmentally responsible, making it an attractive option for homeowners seeking a low-maintenance yet sustainable outdoor living solution.

Manufacturing Process of Composite Decking

The manufacturing process of composite decking is a multifaceted and highly specialized procedure that involves several critical stages to ensure the production of high-quality, durable, and aesthetically pleasing decking materials. This process can be broadly categorized into three key phases: Mixing and Blending, Extrusion and Forming, and Finishing and Treatment. In the initial stage, **Mixing and Blending**, raw materials such as recycled plastics, wood fibers, and additives are combined in precise proportions to create a uniform mixture. This step is crucial as it sets the foundation for the final product's performance characteristics, including strength, durability, and resistance to environmental factors. Following the mixing phase, the composite material undergoes **Extrusion and Forming**, where it is heated and molded into the desired shape. This process involves forcing the mixture through a die to create the specific profile of the decking board, ensuring consistency and precision in every piece. Finally, in **Finishing and Treatment**, the extruded decking boards are subjected to various treatments to enhance their appearance and performance. This may include texturing, coloring, and applying protective coatings to improve resistance to weathering and wear. Understanding these stages is essential for appreciating the complexity and quality inherent in composite decking. Let's delve deeper into the first critical phase: **Mixing and Blending**.

1. Mixing and Blending

In the manufacturing process of composite decking, the critical step of mixing and blending is where the magic begins. This phase involves combining various raw materials to create a homogeneous mixture that will eventually form the durable and aesthetically pleasing decking boards. The primary components include recycled plastics, such as polyethylene or polypropylene, and natural fibers like wood flour or bamboo. These materials are sourced from post-consumer waste and sustainably managed forests, respectively, making composite decking an eco-friendly alternative to traditional wood. The mixing process typically starts with the preparation of the raw materials. The recycled plastics are cleaned, sorted, and ground into fine particles to ensure uniformity. Meanwhile, the natural fibers are processed to remove any impurities and then ground into a consistent texture. Once prepared, these components are fed into large mixing tanks or extruders where they are combined with additives such as UV stabilizers, colorants, and anti-microbial agents. These additives enhance the durability and appearance of the final product by protecting it from sunlight degradation, providing consistent coloration, and preventing mold and mildew growth. The blending process is meticulously controlled to ensure that each component is evenly distributed throughout the mixture. This is crucial because uneven distribution can lead to inconsistencies in the final product's performance and appearance. Advanced machinery, including high-speed mixers and twin-screw extruders, is used to achieve this uniformity. The machinery applies precise amounts of heat and pressure to melt the plastic particles and bind them with the natural fibers, creating a consistent blend. After blending, the mixture is formed into a pelletized form that can be easily fed into extrusion machines during the next stage of production. These pellets are uniform in size and composition, ensuring that each decking board produced will have consistent properties. The quality control measures during this phase are stringent; samples are regularly taken for testing to ensure that the blend meets the required standards for strength, flexibility, and color consistency. The importance of this mixing and blending step cannot be overstated. It sets the foundation for producing high-quality composite decking that is resistant to rot, insects, and weathering while offering a natural look and feel. By carefully selecting and blending raw materials, manufacturers can create products that not only perform well but also contribute to a more sustainable future by reducing waste and conserving natural resources. As a result, homeowners and builders can trust that their composite decking will stand the test of time while also supporting environmentally responsible practices.

2. Extrusion and Forming

In the manufacturing process of composite decking, extrusion and forming are crucial steps that transform raw materials into the final product. **Extrusion** involves forcing a mixture of wood fibers, plastics, and additives through a heated die to create the desired shape. This process begins with the blending of raw materials such as recycled plastics, wood fibers, and various additives like UV stabilizers and colorants. The blend is then fed into an extruder, where it is melted and mixed under high pressure and temperature. The molten mixture is then pushed through a die, which shapes it into the desired profile—typically a plank or board. The extruded material is then cooled and cut to the required length. **Forming** follows extrusion and involves giving the composite material its final shape and texture. After extrusion, the composite decking planks are passed through a series of rollers and molds that impart the desired texture and pattern. This can include wood grain patterns, embossed designs, or other surface finishes that mimic natural wood or provide additional grip. The forming process also ensures that the decking planks have consistent dimensions and quality. Some manufacturers may use additional techniques such as capping, where a protective layer is applied to the surface of the decking to enhance durability and resistance to weathering. The precision and control in both extrusion and forming are key to producing high-quality composite decking. Advanced machinery and quality control measures ensure that each plank meets stringent standards for strength, durability, and aesthetic appeal. The result is a product that offers the benefits of low maintenance, resistance to rot and insect damage, and a long lifespan compared to traditional wood decking. By combining these manufacturing processes, composite decking manufacturers can produce a wide range of products tailored to different consumer needs and preferences, making composite decking an increasingly popular choice for outdoor construction projects.

3. Finishing and Treatment

### Finishing and Treatment The final stages of the composite decking manufacturing process involve meticulous finishing and treatment to ensure the product meets stringent quality standards and enhances its durability and aesthetic appeal. After the extrusion process, the composite decking boards undergo various treatments to achieve the desired texture, color, and performance characteristics. **Surface Texturing:** To mimic the natural look and feel of wood, composite decking boards are often textured. This can be done through embossing or brushing techniques. Embossing involves pressing a pattern onto the surface of the board, while brushing uses a series of rollers to create a wood-grain texture. These textures not only enhance the visual appeal but also provide better traction, reducing the risk of slipping. **Coloring and Pigmentation:** The coloring process is crucial for achieving the desired appearance. Composite decking manufacturers use high-quality pigments that are mixed into the raw materials before extrusion. These pigments are UV-resistant to prevent fading over time, ensuring that the decking retains its vibrant color even after prolonged exposure to sunlight. Some manufacturers also offer additional color treatments post-extrusion, such as applying a stain or paint, although this is less common due to the inherent color stability of composite materials. **Sealing and Coating:** While composite decking is inherently resistant to moisture and rot, some manufacturers apply additional coatings to further enhance its durability. These coatings can include water-repellent treatments or protective layers that shield the decking from extreme weather conditions. Additionally, some products may receive a capstock layer—a thin, durable outer layer that provides extra protection against scratches and fading. **Quality Control:** Before the composite decking boards are packaged and shipped, they undergo rigorous quality control checks. Inspectors verify that each board meets specifications for dimensions, color consistency, texture, and overall quality. Any boards that do not meet these standards are removed from production to ensure that only high-quality products reach consumers. **Packaging and Shipping:** Finally, the finished composite decking boards are carefully packaged to prevent damage during transportation. They are typically bundled together with strapping or wrapped in protective film to safeguard against scratches and other forms of damage. Clear labeling and documentation accompany each shipment to ensure that customers receive accurate information about the product, including installation instructions and maintenance tips. In summary, the finishing and treatment stages of composite decking manufacturing are critical for producing a product that is not only durable but also visually appealing. By combining advanced texturing techniques, high-quality pigments, protective coatings, stringent quality control measures, and careful packaging, manufacturers can deliver composite decking that stands the test of time and enhances any outdoor living space.

Benefits and Characteristics of Composite Decking

Composite decking has emerged as a preferred choice for homeowners and builders alike, offering a myriad of benefits that set it apart from traditional wood decking. One of the most compelling advantages of composite decking is its exceptional durability and longevity, which ensures that it withstands the elements and heavy use over many years. Additionally, composite decking is known for its low maintenance requirements, eliminating the need for frequent staining, sealing, and repairs that are common with wood decks. Furthermore, composite decking is an environmentally sustainable option, as it is often made from recycled materials and reduces the demand for natural wood resources. These characteristics collectively make composite decking an attractive solution for those seeking a reliable, hassle-free, and eco-friendly outdoor living space. Let's delve deeper into the first of these benefits: the remarkable durability and longevity of composite decking.

1. Durability and Longevity

**Durability and Longevity** One of the most compelling benefits of composite decking is its exceptional durability and longevity. Unlike traditional wood decks, which are prone to rot, decay, and damage from insects and weather conditions, composite decking stands the test of time with minimal maintenance. Composite materials are engineered to withstand harsh environmental factors such as heavy rainfall, intense sunlight, and extreme temperatures without compromising their structural integrity. This resilience is due to the combination of high-quality plastics and natural fibers like wood or bamboo, which are blended together to create a robust and weather-resistant material. The durability of composite decking is further enhanced by its resistance to warping, cracking, and splitting. Unlike wood, which can expand and contract with changes in humidity and temperature, composite decking remains stable and consistent in its dimensions. This stability ensures that the deck remains secure and even over years of use, eliminating the need for frequent repairs or replacements. Additionally, composite decking is less susceptible to mold and mildew growth, reducing the risk of health hazards associated with damp environments. Another significant advantage of composite decking is its long lifespan. While traditional wood decks may need to be replaced every 10 to 20 years due to wear and tear, composite decks can last for 25 years or more with proper care. This extended lifespan not only saves homeowners money on replacement costs but also reduces the environmental impact associated with frequent material replacements. Furthermore, many manufacturers offer warranties that cover composite decking for up to 25 years or more, providing homeowners with peace of mind knowing their investment is protected. The low maintenance requirements of composite decking also contribute to its longevity. Unlike wood decks that require regular staining, sealing, and cleaning to maintain their appearance and integrity, composite decks can be cleaned with simple soap and water. This ease of maintenance ensures that the deck remains in good condition without the need for time-consuming and costly upkeep routines. In summary, the durability and longevity of composite decking make it an attractive option for homeowners seeking a reliable and long-lasting outdoor living space. Its ability to withstand various environmental conditions, resist damage from insects and mold, and maintain its structural integrity over decades sets it apart from traditional wood decking. Whether you are looking to enhance your home's aesthetic appeal or create a functional outdoor area that will endure through the seasons, composite decking offers unparalleled benefits in terms of durability and longevity.

2. Low Maintenance Requirements

One of the most compelling benefits of composite decking is its low maintenance requirements, making it an ideal choice for homeowners who value convenience and durability. Unlike traditional wood decks, which demand regular staining, sealing, and replacement of boards due to rot, warping, or insect damage, composite decking offers a hassle-free alternative. Composite materials are engineered to withstand the elements, resisting moisture absorption and the subsequent issues that come with it. This means that composite decks do not require the frequent application of protective coatings or treatments that wood decks need to maintain their integrity. Moreover, composite decking is less prone to warping and splitting, which are common problems with wooden decks exposed to varying temperatures and humidity levels. The composite material's stability ensures that the deck remains structurally sound over time, eliminating the need for frequent repairs or replacements. Additionally, composite decks are resistant to mold, mildew, and insect infestations, further reducing the need for maintenance activities such as cleaning with harsh chemicals or treating for pests. The low maintenance aspect of composite decking also extends to its cleaning requirements. Unlike wood decks that can stain easily from spills or foot traffic, composite decks can be cleaned with simple soap and water. This ease of cleaning not only saves time but also reduces the environmental impact associated with using chemical cleaners. Furthermore, the color and texture of composite decking remain consistent over time, eliminating the need for periodic staining or painting to maintain its appearance. For homeowners with busy lifestyles or those who prefer to spend their leisure time enjoying their outdoor space rather than maintaining it, composite decking is a perfect solution. It allows for more free time to enjoy activities like entertaining guests, gardening, or simply relaxing on the deck without worrying about upkeep. The long-term cost savings from reduced maintenance needs also make composite decking a financially savvy choice in the long run. In summary, the low maintenance requirements of composite decking are a significant advantage over traditional wood decking. By offering resistance to moisture, warping, mold, mildew, and insects, composite decking minimizes the need for frequent repairs and treatments. Its ease of cleaning and consistent appearance over time further enhance its appeal. For homeowners seeking a durable and hassle-free outdoor living space, composite decking stands out as an excellent option.

3. Environmental Sustainability

Environmental sustainability is a critical aspect of composite decking, offering numerous benefits that align with the growing demand for eco-friendly building materials. Composite decking, made from a blend of recycled plastics and natural fibers such as wood, reduces the need for virgin timber and helps in conserving forests. This blend of materials not only minimizes waste but also utilizes post-consumer plastics that would otherwise end up in landfills. By reusing these materials, composite decking manufacturers significantly lower the carbon footprint associated with traditional wood decking, which often involves deforestation and the transportation of raw materials over long distances. Moreover, composite decking requires minimal maintenance compared to traditional wood decks. It resists rot, mold, and insect damage, eliminating the need for chemical treatments and preservatives that can harm the environment. This durability ensures that composite decks last longer, reducing the frequency of replacements and the associated environmental impacts. Additionally, many composite decking products are designed with recyclable components, allowing them to be reused or repurposed at the end of their life cycle, further enhancing their sustainability. The production process of composite decking also contributes to its environmental sustainability. Modern manufacturing techniques ensure that the materials are combined in a way that maximizes resource efficiency and minimizes waste. Some manufacturers even incorporate reclaimed materials from other industries into their products, creating a closed-loop system that promotes circular economy principles. This approach not only conserves resources but also supports a more sustainable supply chain. In terms of long-term benefits, composite decking helps in reducing the overall environmental impact of outdoor construction projects. By choosing composite decking over traditional wood, homeowners and builders can contribute to a reduction in greenhouse gas emissions and support sustainable forestry practices. Furthermore, the longevity of composite decks means fewer resources are needed over time for repairs and replacements, making it a cost-effective and environmentally responsible choice. Overall, the environmental sustainability of composite decking is a compelling reason for its adoption. It combines the benefits of recycled materials, reduced maintenance needs, and a longer lifespan to offer a product that is both eco-friendly and durable. As consumers become increasingly aware of their environmental footprint, the advantages of composite decking make it an attractive option for those seeking to build or renovate outdoor spaces while supporting sustainable practices.