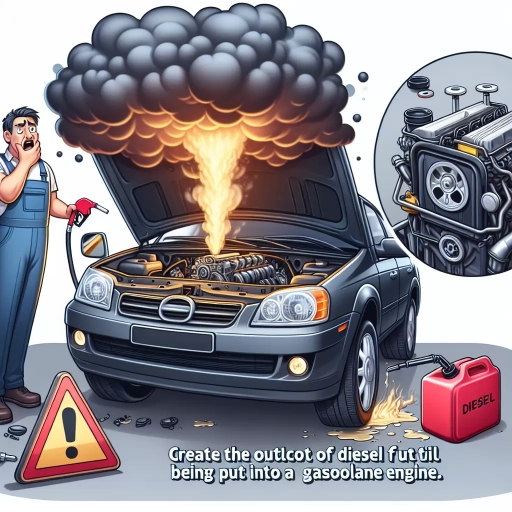

What Happens When You Put Diesel In A Gas Engine

Putting diesel fuel into a gasoline engine is a critical mistake that can have severe and immediate consequences. This error can lead to a cascade of problems, affecting the engine's performance and longevity. In this article, we will delve into the immediate consequences of diesel in a gas engine, exploring how it impacts the vehicle right away. We will also examine the short-term effects on engine components, detailing how diesel fuel can damage critical parts such as fuel injectors, spark plugs, and cylinders. Finally, we will discuss the long-term implications and the associated repair costs, highlighting the financial and mechanical repercussions of this mistake. Understanding these aspects is crucial for car owners to appreciate the gravity of such an error and take preventive measures. Let's begin by examining the immediate consequences of diesel in a gas engine.

Immediate Consequences of Diesel in a Gas Engine

The immediate consequences of putting diesel fuel into a gas engine are severe and multifaceted, posing significant risks to the vehicle's performance and longevity. When diesel fuel is mistakenly introduced into a gas engine, it can lead to engine stalling and failure to start, as the diesel fuel does not ignite properly in the combustion chamber. Additionally, fuel system contamination occurs because diesel fuel is not compatible with the materials used in gasoline fuel systems, causing damage to components such as fuel lines, injectors, and pumps. Initial performance issues also arise due to the incorrect fuel type, resulting in poor engine performance, reduced power output, and potential misfires. Understanding these immediate consequences is crucial for preventing costly repairs and ensuring the overall health of the vehicle. This article will delve into each of these critical areas, starting with the immediate impact on engine stalling and failure to start.

Engine Stalling and Failure to Start

Engine stalling and failure to start are immediate and severe consequences when diesel fuel is mistakenly put into a gasoline engine. The primary reason for this is the fundamental incompatibility between diesel and gasoline engines. Diesel fuel, which is thicker and oilier than gasoline, does not ignite properly in the combustion chamber of a gasoline engine. When diesel is introduced into the fuel system, it can cause several critical issues. First, the fuel injectors become clogged due to the higher viscosity of diesel, preventing the proper atomization of fuel necessary for combustion. This leads to poor engine performance, stalling, and eventually, the engine may refuse to start altogether. Additionally, diesel fuel can damage the fuel pump and other components of the fuel system, as these parts are designed to handle the lighter, more volatile properties of gasoline. The fuel lines and cylinders can also be contaminated, requiring extensive cleaning or replacement to restore engine functionality. Furthermore, if the diesel fuel reaches the catalytic converter, it can cause irreversible damage by clogging the converter's honeycomb structure, leading to costly repairs. In some cases, the engine may need to be completely drained and flushed before it can be restarted, and even then, there is a risk of residual damage affecting long-term engine health. Therefore, it is crucial to address the issue promptly and seek professional assistance to minimize the extent of the damage and ensure the engine's longevity.

Fuel System Contamination

Fuel system contamination is a critical issue that arises when diesel fuel is mistakenly introduced into a gasoline engine. This contamination can lead to immediate and severe consequences, compromising the engine's performance and longevity. Here’s a detailed look at the implications: When diesel fuel enters a gasoline engine, it does not ignite properly due to its higher flash point and lower volatility compared to gasoline. This results in incomplete combustion, causing the diesel fuel to accumulate in the engine's combustion chamber, fuel lines, and fuel injectors. The presence of diesel fuel in these components leads to several immediate problems. Firstly, it can cause the fuel injectors to become clogged or dirty, reducing their ability to spray fuel efficiently. This clogging can lead to poor engine performance, including reduced power output, rough idling, and decreased fuel efficiency. Moreover, diesel fuel can damage the engine's fuel system components such as the fuel pump, fuel lines, and fuel tank. Diesel is less volatile than gasoline and does not evaporate as quickly, which means it can leave behind residues that can corrode or clog these components over time. Additionally, diesel fuel can contaminate the engine oil, leading to a decrease in its lubricating properties and potentially causing wear on moving parts within the engine. The contamination also affects the engine's emissions system. Modern gasoline engines rely on sophisticated emissions control systems, including catalytic converters and oxygen sensors. Diesel fuel can damage these components by depositing soot and other contaminants that reduce their effectiveness, leading to increased emissions and potential failure of these critical systems. In terms of immediate consequences, the introduction of diesel into a gasoline engine can cause the engine to stall or fail to start. If the engine does manage to run, it may experience severe misfires, knocking sounds, or vibrations due to the improper combustion of diesel fuel. In some cases, this can lead to costly repairs or even require the replacement of major engine components. To mitigate these issues, it is crucial to address fuel system contamination promptly. This typically involves draining the fuel tank, flushing the fuel system with clean gasoline, and replacing any contaminated components such as fuel filters and injectors. In severe cases, professional mechanical intervention may be necessary to clean or replace damaged parts. In summary, fuel system contamination from diesel in a gasoline engine is a serious issue that demands immediate attention to prevent long-term damage and costly repairs. Understanding the immediate consequences of this contamination is essential for taking swift action to protect the integrity of the engine and ensure its continued operation.

Initial Performance Issues

When diesel fuel is mistakenly put into a gasoline engine, initial performance issues are immediate and severe. The primary problem arises from the fundamental differences in fuel properties and engine design. Diesel fuel is thicker and oilier than gasoline, which can cause it to clog the fuel injectors and fuel lines. This leads to poor engine performance almost instantly, as the engine struggles to draw in the correct amount of fuel. The fuel system, including the fuel pump, injectors, and lines, can become contaminated with diesel, resulting in reduced power output and rough engine operation. One of the first noticeable symptoms is a decrease in engine performance, often accompanied by stumbling or stalling. The engine may also produce unusual noises such as knocking or clunking sounds due to the improper combustion of diesel fuel in a gasoline engine. Additionally, the exhaust system may emit a strong, unpleasant odor characteristic of diesel fuel. The fuel system's contamination can also lead to issues with the engine's electronic control unit (ECU), which relies on precise fuel measurements to optimize engine performance. Misfires and erratic idling are common as the ECU tries to compensate for the incorrect fuel type. In some cases, the engine might not start at all if the diesel contamination is severe enough. Furthermore, if the vehicle is driven even a short distance with diesel in the gas tank, it can cause significant damage to critical components such as the catalytic converter and oxygen sensors. These components are designed to work with gasoline and can be irreparably damaged by diesel fuel, leading to costly repairs. Immediate action is crucial when diesel is put into a gas engine. The vehicle should be towed to a repair shop without being driven to prevent further damage. A professional mechanic will need to drain the fuel tank, flush the fuel system, and replace any damaged components to restore the engine to its proper functioning state. Ignoring these initial performance issues can lead to more severe and expensive problems down the line, emphasizing the importance of prompt intervention when such a mistake occurs.

Short-Term Effects on Engine Components

The short-term effects on engine components can be detrimental and far-reaching, impacting various critical parts of the engine. When considering these effects, it is essential to examine three key areas: damage to fuel injectors and pumps, clogging of fuel lines and filters, and corrosion of engine parts. Each of these areas highlights a different facet of how short-term issues can compromise engine performance and longevity. For instance, damage to fuel injectors and pumps can lead to inefficient fuel delivery, resulting in poor engine performance and reduced fuel efficiency. Similarly, clogging of fuel lines and filters can restrict fuel flow, causing the engine to run rough or even stall. Additionally, corrosion of engine parts can weaken structural integrity and lead to premature wear. Understanding these short-term effects is crucial for maintaining optimal engine health. Let's delve into the first of these critical issues: damage to fuel injectors and pumps.

Damage to Fuel Injectors and Pumps

When diesel fuel is mistakenly put into a gasoline engine, it can cause significant damage to critical components, particularly the fuel injectors and pumps. Here’s a detailed look at the short-term effects on these vital parts: **Fuel Injectors:** 1. **Clogging and Corrosion:** Diesel fuel is thicker and oilier than gasoline, which can lead to clogging of the fuel injectors. The higher viscosity of diesel can also cause corrosion within the injector nozzles, reducing their ability to spray fuel properly. 2. **Incorrect Spray Pattern:** The design of fuel injectors in gasoline engines is optimized for the lighter, more volatile properties of gasoline. Diesel fuel disrupts this spray pattern, leading to poor combustion and reduced engine performance. 3. **Fuel Injector Failure:** Prolonged exposure to diesel can cause the fuel injectors to fail completely, necessitating costly replacement. **Fuel Pumps:** 1. **Overload and Failure:** Diesel fuel requires more energy to pump due to its higher viscosity compared to gasoline. This increased load can quickly overwhelm the fuel pump, leading to premature failure. 2. **Contamination:** Diesel fuel can contaminate the fuel pump's internal components, causing them to wear down faster and potentially leading to pump failure. 3. **System Pressure Issues:** The incorrect fuel can disrupt the system's pressure balance, causing erratic pump operation and further exacerbating damage. **Immediate Consequences:** - **Engine Stalling:** The immediate effect of diesel in a gasoline engine is often engine stalling or difficulty starting the engine due to the improper fuel mixture. - **Performance Issues:** Even if the engine manages to run, it will likely experience severe performance issues such as rough idling, misfires, and reduced power output. - **Costly Repairs:** The damage to fuel injectors and pumps can be extensive, requiring professional repair or replacement, which can be very costly. In summary, introducing diesel fuel into a gasoline engine wreaks havoc on the fuel injectors and pumps due to their incompatibility with the heavier, oilier properties of diesel. This results in clogged injectors, overloaded pumps, and potentially catastrophic failures that necessitate immediate attention and costly repairs to prevent further damage.

Clogging of Fuel Lines and Filters

When diesel fuel is mistakenly put into a gasoline engine, one of the immediate and critical issues that arise is the clogging of fuel lines and filters. Diesel fuel is much thicker and oilier than gasoline, which makes it incompatible with the fuel system designed for gasoline engines. As soon as diesel fuel enters the fuel lines, it begins to coat the interior surfaces, causing a buildup that restricts the flow of fuel. This clogging can occur rapidly, often within minutes of starting the engine, leading to severe performance issues. The fuel filters, which are designed to capture contaminants and ensure clean fuel reaches the engine, become quickly overwhelmed by the diesel fuel. The filters clog rapidly due to the higher viscosity of diesel, preventing any fuel from passing through. This blockage starves the engine of the necessary fuel, resulting in poor engine performance, stalling, or complete failure to start. Additionally, diesel fuel can dissolve the varnish and other deposits that gasoline engines rely on for lubrication and sealing. This dissolution can lead to further clogging as these dissolved materials mix with the diesel fuel and form a sticky residue that adheres to fuel line walls and filter elements. The combination of these factors—thick diesel fuel coating surfaces and dissolving critical lubricants—creates a highly problematic situation that requires immediate attention to avoid permanent damage to the engine. In summary, clogging of fuel lines and filters is a direct consequence of introducing diesel fuel into a gasoline engine. The thick, oily nature of diesel causes rapid buildup in fuel lines and filters, leading to poor engine performance and potential engine failure. Prompt action is necessary to mitigate these effects and prevent long-term damage to critical engine components.

Corrosion of Engine Parts

When diesel fuel is mistakenly put into a gasoline engine, one of the immediate and severe consequences is the corrosion of engine parts. This occurs because diesel fuel does not evaporate as quickly as gasoline and can leave behind a residue that interferes with the engine's lubrication system. The diesel fuel can mix with the engine oil, diluting its effectiveness and leading to increased wear on moving parts. Additionally, diesel fuel can cause the fuel system components, such as fuel injectors and fuel lines, to corrode due to its higher density and different chemical composition compared to gasoline. This corrosion can lead to premature failure of these components, resulting in costly repairs or even requiring replacement of the entire engine. Furthermore, the combustion process in a gasoline engine is not designed to handle diesel fuel, which can cause incomplete combustion and produce harmful byproducts that further exacerbate corrosion within the engine's cylinders and pistons. As a result, the short-term effects on engine components include significant damage to fuel system components, increased wear on moving parts, and potential failure of critical engine elements, all of which underscore the importance of using the correct type of fuel to avoid such catastrophic outcomes.

Long-Term Implications and Repair Costs

The long-term implications of engine neglect or severe damage can be far-reaching and financially burdensome. When an engine suffers significant wear and tear, it often necessitates an extensive engine overhaul or replacement, a costly and time-consuming process. Additionally, the increased maintenance and repair costs associated with a compromised engine can significantly impact a vehicle's overall operational expenses. Furthermore, there is a potential for permanent engine damage if issues are not addressed promptly, leading to irreversible consequences. Understanding these implications is crucial for vehicle owners to make informed decisions about their engine's health and future maintenance needs. This article will delve into these critical aspects, starting with the necessity of an extensive engine overhaul or replacement.

Extensive Engine Overhaul or Replacement

When considering the long-term implications and repair costs associated with putting diesel in a gas engine, one of the most critical factors is the potential need for an extensive engine overhaul or replacement. If diesel fuel is introduced into a gasoline engine, it can cause severe damage due to the incompatibility of diesel with the engine's design and components. Diesel fuel does not ignite as easily as gasoline and can lead to incomplete combustion, resulting in engine knock or pinging, which can damage pistons, rings, and cylinder walls. Additionally, diesel fuel can clog fuel injectors and fuel lines, further exacerbating the problem. In many cases, the extent of the damage necessitates a comprehensive overhaul of the engine. This involves disassembling the engine to inspect and replace damaged components such as pistons, rings, valves, and cylinder heads. The process also includes cleaning or replacing fuel injectors, fuel lines, and other affected parts. This extensive work requires specialized tools and expertise, significantly increasing labor costs. Furthermore, if the damage is too severe or if critical components are beyond repair, a complete engine replacement may be necessary. Engine replacement involves installing a new or rebuilt engine, which is a costly procedure that includes not only the cost of the new engine but also substantial labor charges. The financial implications of such repairs are substantial. An engine overhaul can cost anywhere from $2,000 to $5,000 or more, depending on the complexity of the job and the specific components that need to be replaced. If an engine replacement is required, costs can escalate to $5,000 to $10,000 or even higher for high-performance vehicles. These figures do not include additional expenses such as towing fees, rental car costs during the repair period, and potential losses due to downtime. Moreover, an extensive engine overhaul or replacement also has long-term implications for vehicle reliability and performance. Even after a successful repair, there may be lingering issues that could affect fuel efficiency, power output, and overall engine longevity. Regular maintenance becomes even more crucial to ensure that the newly repaired or replaced engine operates optimally and lasts as long as possible. In summary, putting diesel in a gas engine can lead to catastrophic consequences that often necessitate an extensive engine overhaul or replacement. These procedures are not only costly but also time-consuming and may have lasting impacts on vehicle performance and reliability. Therefore, it is imperative to avoid such mistakes by ensuring the correct type of fuel is used for your vehicle to prevent these costly and time-consuming repairs.

Increased Maintenance and Repair Costs

When you put diesel in a gas engine, one of the most significant long-term implications is the substantial increase in maintenance and repair costs. Diesel fuel is thicker and oilier than gasoline, which can lead to severe engine damage if not promptly addressed. The initial mistake can result in clogged fuel injectors, fuel lines, and engine components, necessitating costly repairs. For instance, the fuel injectors may need to be replaced or thoroughly cleaned, which can cost anywhere from $500 to $2,000 depending on the vehicle model and extent of damage. Additionally, the fuel system may require flushing to remove all traces of diesel fuel, adding another layer of expense. The engine itself could suffer from reduced performance or even complete failure if diesel fuel is allowed to circulate through it for an extended period. This could mean replacing critical components such as pistons, rings, or even the entire engine block, significantly escalating the repair bill. In some cases, the damage might be so extensive that it becomes more economical to replace the engine altogether, which can cost between $3,000 to $10,000 or more. Moreover, modern vehicles often have sophisticated fuel systems and computer controls that can be affected by the wrong type of fuel. The onboard computer may need reprogramming or replacement after being exposed to diesel fuel, further adding to the overall cost. The labor costs for these repairs are also considerable, as they often require specialized tools and expertise. In summary, putting diesel in a gas engine leads to increased maintenance and repair costs due to the potential for extensive damage to fuel injectors, engine components, and other critical systems. Prompt action is crucial to mitigate these costs, but even then, the financial impact can be substantial. Therefore, it is imperative to ensure the correct type of fuel is used to avoid these costly consequences.

Potential for Permanent Engine Damage

When diesel fuel is mistakenly put into a gasoline engine, the potential for permanent engine damage is significant and should not be underestimated. Diesel fuel is much thicker and oilier than gasoline, which can lead to severe consequences when it interacts with the engine's components designed for gasoline. Here are the key points to consider: 1. **Fuel System Clogging**: Diesel fuel can clog the fuel injectors, fuel lines, and fuel pump due to its higher viscosity. This can prevent the engine from getting the proper amount of fuel, leading to poor performance or complete engine failure. 2. **Engine Oil Contamination**: Diesel fuel can mix with the engine oil, diluting it and reducing its lubricating properties. This contamination can cause wear on moving parts, such as piston rings and cylinder walls, leading to premature wear and potential seizure. 3. **Catalytic Converter Damage**: The catalytic converter is sensitive to diesel fuel and can be irreparably damaged if exposed to it. This component is crucial for emissions control, and its failure can result in costly repairs. 4. **Fuel Injector Failure**: Diesel fuel can cause the fuel injectors to fail because they are not designed to handle the thicker fuel. Replacing fuel injectors can be expensive and time-consuming. 5. **Engine Seizure**: In severe cases, the combination of clogged fuel systems and contaminated engine oil can cause the engine to seize. This is often a catastrophic failure that requires a new engine or extensive repairs. 6. **Electronic Control Unit (ECU) Damage**: Modern engines rely on sophisticated electronics to manage fuel injection and other critical functions. Diesel fuel can damage these electronic components, leading to costly repairs or replacement. Given these risks, it is crucial to address the issue immediately if diesel fuel is accidentally put into a gasoline engine. The sooner the problem is identified and rectified, the less likely it is that permanent damage will occur. However, even with prompt action, there may still be long-term implications and significant repair costs involved in restoring the engine to its original condition. Therefore, prevention through careful fueling practices remains the best strategy to avoid these costly and potentially disastrous outcomes.