What Is Bone China Made Of

Bone china, renowned for its exceptional strength, translucency, and fine texture, has been a cornerstone of luxury tableware for centuries. This high-quality ceramic material is not just aesthetically pleasing but also boasts a unique composition and manufacturing process that sets it apart from other types of porcelain. To understand the essence of bone china, it is crucial to delve into its composition, which includes a specific blend of bone ash, feldspar, and quartz. The manufacturing process involves precise steps that ensure the material's durability and beauty. Additionally, the properties of bone china, such as its resistance to thermal shock and its ability to be molded into intricate designs, make it highly versatile for various uses. In this article, we will explore the composition of bone china in detail, followed by an examination of its manufacturing process and the properties that make it so valuable. Let us begin by uncovering the composition of bone china.

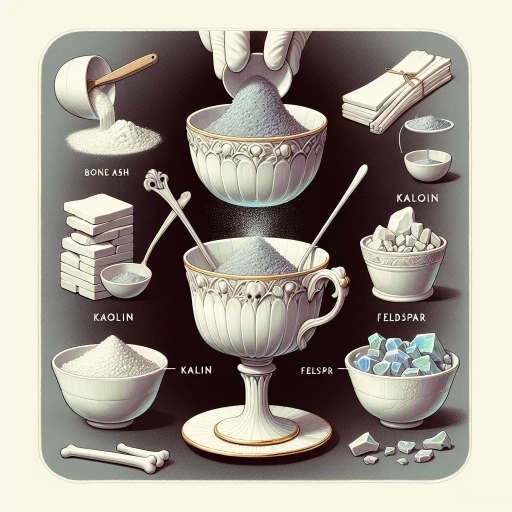

Composition of Bone China

Bone China, a type of porcelain renowned for its strength, whiteness, and durability, is composed of three primary materials: bone ash, kaolin, and feldspar. These components are crucial in defining the unique characteristics of Bone China. Bone ash, derived from animal bones, plays a pivotal role in enhancing the strength and whiteness of the final product. Kaolin and feldspar, on the other hand, contribute significantly to the durability and overall quality of Bone China. Understanding the specific roles of each material is essential to appreciating the craftsmanship and science behind this high-quality ceramic. In this article, we will delve into the primary materials used in Bone China, starting with an examination of bone ash, kaolin, and feldspar.

Primary Materials: Bone Ash, Kaolin, and Feldspar

Bone china, renowned for its translucency, whiteness, and strength, is composed of three primary materials: bone ash, kaolin, and feldspar. **Bone Ash**, derived from animal bones (typically cattle), is calcined to produce a fine powder rich in calcium and phosphorus. This component enhances the material's whiteness and translucency, while also contributing to its durability and resistance to thermal shock. **Kaolin**, a type of clay, adds plasticity to the mixture, allowing it to be shaped and molded with ease. Its presence also helps in achieving a smooth, even texture in the final product. **Feldspar**, a mineral that acts as a flux, lowers the melting point of the other components, facilitating the firing process at high temperatures. This ensures that the bone china achieves its characteristic hardness and stability without compromising its aesthetic qualities. The precise combination of these materials is crucial. Bone ash typically constitutes about 50% of the mixture, providing the necessary strength and translucency. Kaolin makes up around 25%, contributing to the plasticity and smoothness of the material. Feldspar, usually around 25%, ensures that the mixture can be fired at a lower temperature while maintaining its structural integrity. This balanced composition allows bone china to exhibit superior qualities such as fine grain, high strength, and excellent resistance to scratches and chips. The synergy between these primary materials is what sets bone china apart from other types of ceramics, making it highly sought after for fine china and decorative pieces. Understanding the role of each component is essential for appreciating the craftsmanship and science behind creating this exquisite material.

Role of Bone Ash in Strength and Whiteness

Bone ash, derived from calcined animal bones, plays a crucial role in enhancing both the strength and whiteness of bone china. Comprising primarily of tricalcium phosphate (Ca₃(PO₄)₂), bone ash acts as a flux that lowers the melting point of other materials in the bone china composition, such as feldspar and quartz. This reduction in melting point allows for a more efficient firing process, resulting in a stronger and more durable final product. The presence of bone ash also contributes to the translucency and whiteness of bone china by reducing the iron content, which can cause discoloration. Additionally, bone ash helps to create a more stable and consistent glaze fit, ensuring that the glaze adheres well to the body of the ceramic without cracking or crazing. This combination of improved strength, enhanced whiteness, and better glaze fit makes bone ash an indispensable component in the production of high-quality bone china. Its inclusion is what sets bone china apart from other types of ceramics, offering a unique blend of aesthetic appeal and functional durability.

Importance of Kaolin and Feldspar in Durability

Kaolin and feldspar are pivotal components in the composition of bone china, significantly enhancing its durability. Kaolin, also known as china clay, is a soft, white mineral that provides plasticity and strength to the ceramic body. Its fine particle size allows for better packing and sintering, which improves the overall density and mechanical strength of bone china. When fired at high temperatures, kaolin transforms into a glassy phase that binds other components together, contributing to the material's toughness and resistance to cracking. Feldspar, on the other hand, acts as a flux in the bone china mixture. It lowers the melting point of other materials, facilitating the formation of a glassy matrix during firing. This glassy phase not only enhances the translucency and whiteness of bone china but also increases its durability by creating a more uniform and robust structure. The presence of feldspar helps in achieving a higher firing temperature without compromising the integrity of the ceramic, thereby ensuring that bone china remains resistant to thermal shock and mechanical stress. Together, kaolin and feldspar form a synergistic combination that optimizes the physical properties of bone china. The combination of kaolin's strength and feldspar's fluxing action results in a material that is both aesthetically pleasing and functionally robust. This synergy is crucial for bone china's durability, enabling it to withstand everyday use without losing its integrity or appearance. In essence, the inclusion of kaolin and feldspar in bone china ensures that it maintains its signature translucency, whiteness, and strength, making it a preferred choice for fine china and other high-quality ceramic products.

Manufacturing Process of Bone China

The manufacturing process of bone china is a complex and meticulous series of steps that transform raw materials into exquisite, durable, and translucent ceramic products. This process can be broadly divided into three critical stages: Raw Material Preparation and Mixing, Forming and Shaping Techniques, and Firing and Glazing Processes. Each stage is crucial for achieving the desired quality and aesthetic of bone china. The journey begins with the careful selection and preparation of raw materials, including bone ash, feldspar, and quartz, which are meticulously mixed to create a uniform blend. This initial step sets the foundation for the entire manufacturing process, ensuring that the final product meets the high standards associated with bone china. Understanding these stages is essential for appreciating the craftsmanship and technology involved in producing this premium ceramic material. Let's delve into the first stage: Raw Material Preparation and Mixing.

Raw Material Preparation and Mixing

Raw material preparation and mixing are crucial steps in the manufacturing process of bone china, a type of porcelain known for its translucency, whiteness, and strength. The process begins with the selection and preparation of three primary raw materials: bone ash, feldspar, and quartz. Bone ash, derived from animal bones, typically cattle or pig bones, is calcined at high temperatures to remove organic matter, resulting in a fine powder rich in calcium phosphate. Feldspar, a mineral that acts as a flux to lower the melting point of the mixture, is ground into a fine powder. Quartz, or silica, adds strength and durability to the final product and is also finely ground. These raw materials are then mixed in specific proportions, typically around 50% bone ash, 25% feldspar, and 25% quartz. The precise ratio can vary depending on the desired properties of the final product. The mixing process involves blending these powders thoroughly to ensure uniformity. This can be done using various methods such as ball milling or attrition milling, which help to achieve a consistent particle size distribution. After mixing, the blend is often moistened with water to create a workable paste or slip. This slip is then further refined through processes like filtering and settling to remove any impurities that could affect the quality of the bone china. The consistency of the slip is critical; it must be fluid enough to be cast or molded but not so watery that it loses shape. The prepared slip is then ready for shaping into various forms such as plates, cups, or figurines using techniques like slip casting, jiggering, or hand molding. Once shaped, these pieces undergo drying to remove excess moisture before being fired in a kiln at high temperatures (typically around 1250°C) to achieve the desired hardness and translucency. Throughout this process, careful control over raw material quality and mixing ratios is essential to ensure that the final bone china products meet the required standards of strength, whiteness, and translucency. Any deviations in these steps can lead to defects such as warping, cracking, or discoloration, making raw material preparation and mixing foundational to producing high-quality bone china.

Forming and Shaping Techniques

In the manufacturing process of bone china, forming and shaping techniques are crucial steps that determine the final product's quality and aesthetic appeal. These techniques involve transforming raw materials into the desired shape, ensuring precision and consistency. Here are the key methods: 1. **Slip Casting**: This is a widely used method for producing intricate and delicate shapes. A liquid mixture of bone china material, known as slip, is poured into a plaster mold. The water is absorbed by the mold, leaving a layer of material that can be removed and further processed. 2. **Press Molding**: This technique involves using a machine to press the bone china material into a mold. It is particularly useful for producing uniform pieces such as plates and cups. The pressure ensures that the material is evenly distributed, reducing the risk of defects. 3. **Jiggering**: This method combines elements of slip casting and press molding. A machine with a rotating head shapes the material into the desired form while it is still in a semi-liquid state. Jiggering is often used for flatware like plates and saucers. 4. **Hand Throwing**: Skilled artisans use potter's wheels to shape bone china into various forms, such as vases and teacups. This traditional method allows for greater creativity and customization but requires significant skill and time. 5. **Injection Molding**: Although less common in bone china production due to its complexity, injection molding involves forcing a mixture of bone china material into a mold under high pressure. This method is efficient for mass production but may lack the finesse of other techniques. 6. **Casting with Templates**: For more complex shapes, templates or patterns are used to guide the shaping process. This can be done manually or with the aid of machinery, ensuring that each piece meets specific dimensions and design requirements. Each of these forming and shaping techniques has its own advantages and is chosen based on the specific requirements of the product being manufactured. The choice of method depends on factors such as the desired shape, production volume, and the level of detail required. By mastering these techniques, manufacturers can produce bone china items that are not only functional but also visually appealing and durable.

Firing and Glazing Processes

In the manufacturing process of bone china, the firing and glazing processes are crucial steps that transform raw materials into a durable, translucent, and aesthetically pleasing final product. **Firing** involves subjecting the bone china body to high temperatures in a kiln to achieve the desired physical properties. There are typically two firing stages: the first firing, known as "bisque firing," occurs at a lower temperature (around 1800°F or 980°C) to remove excess moisture and create a hard, brittle surface called "bisque." This stage is essential for preparing the piece for glazing. The second firing, or "glost firing," takes place at an even higher temperature (around 2400°F or 1300°C) after the application of glaze. This process melts the glaze, forming a glassy surface that is both durable and decorative. **Glazing** is the application of a layer of glaze to the bisque-fired bone china. Glazes are mixtures of chemicals that, when fired, form a glass-like surface. The composition of the glaze can vary widely, allowing for a range of colors and finishes. For bone china, the glaze must be carefully formulated to ensure it adheres well to the body and does not crack or craze (develop fine cracks) over time. The glazing process typically involves dipping or spraying the glaze onto the bisque-fired piece, followed by a thorough inspection to ensure even coverage. Some glazes may require additional firings at different temperatures to achieve specific effects, such as underglaze colors or overglaze enamels. The combination of these firing and glazing processes is what gives bone china its unique characteristics: strength, whiteness, translucency, and resistance to scratches and stains. The precise control over temperature and glaze composition during these stages ensures that the final product meets the high standards associated with bone china. This meticulous attention to detail in the firing and glazing processes underscores the craftsmanship and technological expertise involved in producing this premium ceramic material.

Properties and Uses of Bone China

Bone china, renowned for its exceptional quality and versatility, is a material that has captivated artisans and consumers alike for centuries. This unique ceramic material is distinguished by several key properties that make it highly desirable. First, its translucency and aesthetic appeal set it apart from other types of ceramics, allowing it to showcase intricate designs and colors with unparalleled clarity. Additionally, bone china is celebrated for its strength, durability, and resistance to chips, making it a practical choice for everyday use. Lastly, its applications extend beyond functional tableware to include exquisite decorative items, highlighting its adaptability and artistic value. These attributes collectively contribute to the enduring popularity of bone china, making it a staple in both traditional and modern settings. As we delve into the specifics of bone china, we begin by exploring its most striking feature: its translucency and aesthetic appeal.

Translucency and Aesthetic Appeal

Translucency and aesthetic appeal are pivotal attributes of bone china, significantly contributing to its enduring popularity and versatility in both functional and decorative applications. Bone china's unique translucency is a direct result of its composition, which includes a high percentage of bone ash (calcined animal bones), feldspar, and quartz. When fired at extremely high temperatures, these components fuse to create a dense, fine-grained body that allows light to pass through, giving bone china its characteristic luminosity. This translucency not only enhances the visual appeal of bone china but also makes it ideal for crafting delicate, intricate designs that seem almost ethereal. The aesthetic appeal of bone china is multifaceted. Its whiteness and translucency provide an excellent canvas for various decorative techniques such as underglaze blue and white, overglaze enameling, and gilding. The material's smooth, fine texture allows for precise and detailed craftsmanship, enabling artisans to create intricate patterns and designs that are both visually striking and durable. Additionally, bone china's strength and resistance to chipping and cracking ensure that its beauty is not compromised by practical use, making it a preferred choice for fine dining and decorative pieces. In terms of historical significance, bone china has been a cornerstone of ceramic artistry for centuries, particularly in European and Asian traditions. Its ability to mimic the appearance of porcelain while offering greater durability has made it a favorite among ceramic artists and manufacturers. The translucency and aesthetic appeal of bone china have also influenced its use in various cultural contexts, from formal table settings to artistic sculptures and figurines. Moreover, the versatility of bone china extends beyond traditional applications. Modern designers and artists continue to explore new ways to leverage its unique properties, incorporating it into contemporary designs that blend traditional craftsmanship with modern aesthetics. This fusion of old and new techniques ensures that bone china remains relevant and appealing to a wide range of audiences, from collectors of antique ceramics to enthusiasts of contemporary art. In summary, the translucency and aesthetic appeal of bone china are fundamental aspects of its enduring appeal. These qualities, combined with its strength and versatility, make bone china an indispensable material in both historical and contemporary contexts, ensuring its continued relevance in the world of ceramics and beyond.

Strength, Durability, and Resistance to Chips

Bone china, renowned for its exceptional properties, stands out particularly for its strength, durability, and resistance to chips. This ceramic material, composed of a combination of bone ash, feldspar, and quartz, is fired at high temperatures to achieve a unique set of characteristics. The inclusion of bone ash, which is derived from animal bones, significantly enhances the mechanical strength of bone china. This organic component acts as a flux, reducing the firing temperature and allowing for a more uniform and dense structure. As a result, bone china exhibits superior tensile strength compared to other types of porcelain, making it less prone to cracking and breaking under stress. The durability of bone china is another hallmark of its quality. Unlike other ceramics that may degrade over time due to exposure to moisture or thermal shock, bone china retains its integrity. Its dense and vitrified body resists water absorption, which is crucial for maintaining its structural integrity and preventing the growth of bacteria or mold. This property makes bone china ideal for tableware and kitchen utensils that are frequently exposed to water and varying temperatures. Resistance to chips is another critical aspect where bone china excels. The high firing temperature and specific composition of bone china create a hard, non-porous surface that is highly resistant to chipping and cracking. This resilience ensures that bone china products can withstand the rigors of daily use without showing signs of wear and tear. Whether it's fine dining or everyday use, bone china's chip resistance guarantees that the items remain in pristine condition for a long time. In practical terms, these properties translate into a range of uses that highlight the versatility of bone china. It is widely used in the manufacture of fine china dinnerware, teacups, and other tableware due to its elegance and durability. Additionally, bone china's strength and resistance make it suitable for decorative items such as figurines and ornaments that require both aesthetic appeal and longevity. The combination of these attributes—strength, durability, and chip resistance—solidifies bone china's position as a premium material in the world of ceramics, making it a preferred choice for both functional and decorative applications.

Applications in Tableware and Decorative Items

Bone china, renowned for its exceptional strength, translucency, and whiteness, has found widespread applications in both tableware and decorative items. In tableware, bone china is highly valued for its durability and resistance to chipping and cracking, making it an ideal material for fine dining sets, tea services, and everyday dishes. Its non-porous nature ensures that it does not absorb flavors or odors, maintaining the taste and aroma of food. Additionally, bone china's ability to withstand high temperatures allows it to be safely used in both the oven and microwave, enhancing its versatility in modern kitchens. In the realm of decorative items, bone china's aesthetic appeal is equally compelling. Its fine texture and translucency make it a preferred choice for intricate designs and delicate patterns, often seen in figurines, vases, and other ornamental pieces. The material's whiteness provides a pristine canvas for artists to apply a wide range of colors and designs, from subtle pastels to vibrant hues. This versatility in decoration has led to the creation of exquisite pieces that are not only functional but also serve as beautiful additions to any home decor. Moreover, the historical significance of bone china has made it a sought-after material for collectors and enthusiasts. Antique bone china pieces are highly prized for their craftsmanship and the stories they tell about past eras. Modern manufacturers continue this tradition by producing pieces that blend traditional techniques with contemporary designs, ensuring that bone china remains relevant and cherished in today's market. The combination of bone china's practical properties and its artistic potential has solidified its position as a premier material in both tableware and decorative items. Whether it is used to create elegant dinner plates or intricate figurines, bone china stands out for its elegance, durability, and timeless appeal. This dual functionality underscores why bone china remains a staple in many households and a favorite among artisans and collectors alike.