What Is The Difference Between Inkjet And Laser Printers

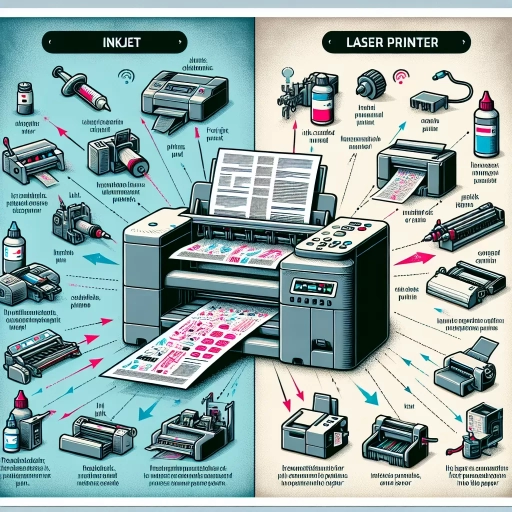

When it comes to choosing the right printer for your needs, understanding the differences between inkjet and laser printers is crucial. These two types of printers vary significantly in their printing technology and mechanism, cost and efficiency, and print quality and versatility. Inkjet printers use a combination of ink droplets to create images on paper, while laser printers employ a laser beam to produce high-quality text and images. The cost and efficiency of these printers also differ, with laser printers often being more economical in the long run despite higher initial costs. Additionally, the print quality and versatility of each type cater to different user needs, with inkjet printers excelling in color printing and laser printers providing crisp text output. In this article, we will delve into these key differences, starting with an in-depth look at the printing technology and mechanism behind each type of printer.

Printing Technology and Mechanism

Printing technology has evolved significantly over the years, offering a range of mechanisms that cater to various needs and preferences. At the heart of this evolution are inkjet and laser printers, each with its unique operational principles and advantages. This article delves into the intricacies of these printing technologies, starting with an in-depth look at **How Inkjet Printers Work**. Inkjet printers rely on the precise ejection of ink droplets onto paper to create images and text, leveraging thermal or piezoelectric printheads to achieve high resolution and color accuracy. Following this, we explore **How Laser Printers Work**, which utilize a laser beam to create an electrostatic image on a drum, attracting toner particles that are then transferred to paper. Finally, we provide a **Comparison of Printing Processes**, highlighting the differences in speed, cost, and quality between inkjet and laser printing. By understanding these mechanisms, users can make informed decisions about which technology best suits their printing needs. Let's begin by examining the inner workings of inkjet printers and how they produce vibrant, detailed prints.

How Inkjet Printers Work

Inkjet printers operate by propelling tiny droplets of ink onto a substrate, typically paper, to create the desired image or text. The core mechanism involves a print head that moves back and forth across the paper, depositing ink droplets with precision. Here’s a detailed breakdown of the process: 1. **Print Head Movement**: The print head is mounted on a carriage that moves horizontally across the paper. This movement is controlled by a belt and pulley system or a linear motor, ensuring accurate and consistent positioning. 2. **Ink Droplet Formation**: Inside the print head, there are numerous tiny nozzles, each capable of producing ink droplets. These nozzles are usually arranged in a linear array and are controlled by electrical signals that determine when and how much ink to release. 3. **Thermal or Piezoelectric Technology**: Inkjet printers use either thermal or piezoelectric technology to expel ink droplets. Thermal inkjet printers heat the ink to create vapor bubbles, which force the ink out of the nozzles. Piezoelectric inkjet printers use electrically charged crystals that change shape when an electric current is applied, pushing the ink out. 4. **Droplet Placement**: As the print head moves, it deposits ink droplets onto the paper in a precise pattern. The spacing and timing of these droplets are crucial for achieving high-quality prints with good resolution and color accuracy. 5. **Paper Feed Mechanism**: The paper is fed through the printer by rollers that pull it from a feed tray. The paper’s movement is synchronized with the print head’s movement to ensure that the ink droplets are deposited in the correct positions. 6. **Color Printing**: For color printing, inkjet printers typically use a combination of cyan, magenta, yellow, and black (CMYK) inks. The print head may have separate nozzles for each color or use a single set of nozzles that switch between different ink reservoirs. 7. **Maintenance and Cleaning**: To maintain print quality, inkjet printers often have built-in cleaning cycles that clear clogged nozzles and ensure proper ink flow. Some models also feature automatic head alignment and calibration processes. In summary, inkjet printers rely on the precise movement of a print head and the controlled release of ink droplets to produce high-quality prints. The combination of advanced technologies in droplet formation and placement allows for detailed and vibrant output, making inkjet printers a popular choice for both home and professional use.

How Laser Printers Work

Laser printers operate through a complex yet efficient process that leverages electrostatic charges, laser light, and toner particles to produce high-quality prints. Here’s a detailed breakdown of how they work: 1. **Initialization**: The printing process begins when the printer receives a print job from the computer. The printer's control unit interprets the data and prepares the necessary instructions for printing. 2. **Charging**: A corona wire or primary charging roller charges the drum, a cylindrical component coated with a photoconductive material, to a high voltage. This creates an electrostatic field across the drum. 3. **Exposure**: A laser beam, controlled by the printer's control unit, scans the drum in a precise pattern. Where the laser hits the drum, it neutralizes the electrostatic charge, creating an electrostatic image that mirrors the desired print. 4. **Toner Application**: Toner, a mixture of pigment and polymer, is attracted to the areas of the drum where the electrostatic charge remains. This is because toner particles are given an opposite charge to that of the drum. 5. **Transfer**: The drum then rolls over a sheet of paper, transferring the toner particles onto it. The paper is given a slight positive charge to attract the negatively charged toner particles. 6. **Fusing**: After toner transfer, the paper passes through a fuser unit consisting of a heated roller and a pressure roller. The heat melts the toner, bonding it to the paper, while the pressure ensures it adheres firmly. 7. **Cleaning**: Finally, the drum is cleaned by removing any residual toner and discharging it to prepare for the next print cycle. This mechanism allows laser printers to produce crisp, high-resolution prints at rapid speeds, making them ideal for high-volume printing needs such as in offices and commercial environments. The precision of laser technology also ensures minimal waste and consistent quality, setting it apart from inkjet printers which use liquid ink and a different printing mechanism.

Comparison of Printing Processes

When comparing printing processes, particularly between inkjet and laser printers, several key differences emerge that impact performance, cost, and suitability for various applications. **Inkjet Printers** use a mechanism where tiny droplets of ink are sprayed onto the paper to form images. This process allows for high-quality color printing and is often preferred for photo printing due to its ability to produce a wide range of colors. Inkjet printers are generally more affordable to purchase upfront but can be more expensive in the long run due to the cost of ink cartridges. They are versatile and can print on various types of paper, including glossy photo paper and even fabric. However, they tend to be slower than laser printers and may not be as durable. **Laser Printers**, on the other hand, use a laser beam to create an electrostatic image on a drum, which attracts toner particles that are then transferred to the paper. This process results in crisp, high-resolution text and is particularly well-suited for high-volume black-and-white printing. Laser printers are faster and more efficient for bulk printing tasks, making them ideal for office environments. While they are typically more expensive to purchase initially, their cost per page is lower over time because toner cartridges last longer than ink cartridges. However, laser printers are generally less versatile in terms of the types of media they can handle and are not as adept at producing high-quality color images as inkjet printers. In terms of **Print Quality**, inkjet printers excel in color reproduction and are better suited for detailed graphics and photos. Laser printers, however, offer superior text quality with sharper lines and clearer fonts, making them the preferred choice for documents and reports. **Speed** is another significant factor; laser printers are generally much faster than inkjet printers, especially when it comes to printing large volumes of text. **Maintenance** also varies between the two technologies. Inkjet printers require more frequent cleaning of the print heads to prevent clogging, which can be time-consuming. Laser printers, while requiring occasional toner replacement, tend to have fewer maintenance needs overall. **Environmental Impact** is another consideration. Laser printers typically use more energy than inkjet printers but produce less waste due to the longer lifespan of toner cartridges compared to ink cartridges. However, the production process for toner cartridges often involves more complex materials and manufacturing steps. In summary, the choice between inkjet and laser printers depends on your specific needs. If you prioritize high-quality color printing and versatility in media types, an inkjet printer is likely the better option. For high-volume text printing with a focus on speed and cost efficiency, a laser printer is the way to go. Understanding these differences helps you make an informed decision that aligns with your printing requirements and budget.

Cost and Efficiency

When evaluating the cost and efficiency of a printing solution, several key factors come into play. Initially, the **Initial Purchase Costs** must be considered, as this upfront investment can significantly impact overall budgeting. Beyond the initial outlay, **Operating Costs and Ink/Toner Expenses** play a crucial role in long-term financial sustainability. These recurring expenses can add up quickly and affect the total cost of ownership. Additionally, **Print Speed and Productivity** are vital for ensuring that the printing solution aligns with operational needs, maximizing output while minimizing downtime. Understanding these interrelated aspects is essential for making an informed decision that balances cost with efficiency. By carefully assessing these elements, businesses can optimize their printing operations to achieve both fiscal responsibility and operational excellence. Let's start by examining the **Initial Purchase Costs**, which set the stage for all subsequent considerations.

Initial Purchase Costs

When considering the difference between inkjet and laser printers, one of the critical factors to evaluate is the initial purchase cost. Generally, inkjet printers are more affordable upfront compared to laser printers. Inkjet printers can be purchased for as low as $20 to $100, making them an attractive option for those on a tight budget or who only need occasional printing. In contrast, laser printers typically start at around $100 and can go up to several hundred dollars, especially for high-quality models designed for heavy-duty use. However, it's essential to consider that the initial cost is just one part of the overall expense. While laser printers may be more expensive to buy initially, they often offer better long-term value due to their lower cost per page. Laser printers use toner cartridges that last significantly longer than the ink cartridges used in inkjet printers. This means that over time, the cost of replacing ink cartridges in an inkjet printer can add up, potentially making the laser printer a more cost-effective choice despite its higher initial price. Additionally, the quality and durability of the printer should also be factored into the initial purchase decision. Laser printers are generally built to last longer and handle more print volume without degradation in print quality. This durability can extend the lifespan of the printer, reducing the need for frequent replacements and further justifying the higher upfront cost. In summary, while inkjet printers may offer a lower initial purchase cost, laser printers often provide better value in the long run due to their lower operating costs and longer lifespan. When evaluating the difference between these two types of printers, it's crucial to consider not just the initial expense but also the ongoing costs and overall efficiency of each option. This comprehensive approach will help you make an informed decision that aligns with your printing needs and budget constraints.

Operating Costs and Ink/Toner Expenses

When evaluating the cost and efficiency of printers, operating costs and ink/toner expenses are crucial factors to consider. Between inkjet and laser printers, the differences in these costs can significantly impact your budget and overall printing experience. For inkjet printers, operating costs are generally higher due to the frequent need for ink replacements. Ink cartridges tend to be more expensive and have a shorter lifespan compared to laser toner cartridges. On average, inkjet printers can cost between $0.05 to $0.20 per page for black and white printing and up to $0.50 per page for color printing. This is because inkjet printers use liquid ink, which is more prone to drying out and requires more frequent replacements. In contrast, laser printers offer lower operating costs over time. Laser toner cartridges are more durable and can print thousands of pages before needing replacement. The cost per page for laser printers is typically lower, ranging from $0.02 to $0.10 for black and white printing and up to $0.20 for color printing. This makes laser printers a more economical choice for high-volume printing needs. Additionally, laser toner cartridges often come in larger sizes, which means fewer replacements are needed, reducing waste and the environmental impact associated with frequent cartridge disposal. However, the initial purchase price of laser printers is usually higher than that of inkjet printers, which can be a significant upfront cost. In terms of efficiency, laser printers also have an edge due to their faster print speeds and higher page yields. This makes them ideal for office environments or any setting where high-volume printing is required. Inkjet printers, while suitable for home use or low-volume printing, may not be as efficient in these scenarios. Ultimately, the choice between an inkjet and laser printer should be based on your specific printing needs and budget constraints. If you prioritize cost-effectiveness and high-volume printing efficiency, a laser printer is likely the better option. However, if you are looking for a more affordable initial investment with acceptable performance for occasional use, an inkjet printer might be sufficient. Understanding these differences in operating costs and ink/toner expenses will help you make an informed decision that aligns with your needs and maximizes your printing efficiency.

Print Speed and Productivity

When it comes to print speed and productivity, the difference between inkjet and laser printers is significant. Laser printers generally outperform inkjet printers in terms of speed and efficiency. Laser printers use a laser beam to create an electrostatic image on a drum, which attracts toner particles to form the printed image. This process allows laser printers to produce high-quality text and graphics at much faster rates compared to inkjet printers. On average, laser printers can print black and white documents at speeds ranging from 20 to 50 pages per minute (ppm), while color documents can be printed at speeds of up to 30 ppm. In contrast, inkjet printers use a series of nozzles to spray ink onto the paper, which results in slower print times. Inkjet printers typically print black and white documents at speeds of around 5 to 20 ppm and color documents at speeds of up to 10 ppm. This disparity in print speed directly impacts productivity, making laser printers more suitable for high-volume printing environments such as offices and commercial settings. For instance, in a busy office where multiple users need to print frequently, a laser printer can handle the workload more efficiently, reducing wait times and increasing overall productivity. Moreover, laser printers often have higher duty cycles, meaning they can handle more prints per month without needing maintenance or replacement parts. This durability further enhances their productivity and makes them a better choice for environments where reliability is crucial. Additionally, laser printers tend to have lower cost per page for black and white printing, especially for large volumes, which can lead to significant cost savings over time. In summary, the superior print speed and higher productivity of laser printers make them ideal for environments requiring high-volume printing, while inkjet printers are better suited for smaller, less frequent printing needs. This difference in performance directly influences the cost and efficiency considerations when choosing between these two types of printers.

Print Quality and Versatility

Print quality and versatility are paramount in today's printing landscape, where precision and adaptability are key to producing outstanding results. A high-quality print is not just about aesthetics; it also involves technical aspects such as resolution and detail, color accuracy and vibrancy, and media compatibility and specialized printing. Resolution and detail are fundamental to achieving crisp, clear images that capture every nuance. High-resolution prints ensure that even the smallest details are preserved, making them ideal for applications where clarity is crucial. Color accuracy and vibrancy play a significant role in enhancing the visual appeal of prints. Accurate color representation ensures that the final product looks as intended, while vibrant colors add depth and emotion to the output. Media compatibility and specialized printing allow for a wide range of creative possibilities. From standard paper to specialized materials like canvas or metal, the ability to print on various media opens up new avenues for artistic expression and functional use. Understanding these elements is essential for anyone looking to produce high-quality prints. Let's delve deeper into the first of these critical factors: resolution and detail.

Resolution and Detail

When it comes to print quality and versatility, one of the key differentiators between inkjet and laser printers is the resolution and detail they can achieve. Resolution, measured in dots per inch (DPI), determines how finely detailed the printed image will be. Inkjet printers typically offer high resolutions, often up to 9600 DPI or more, which allows for crisp text and vibrant, detailed images. This makes them ideal for printing photographs, artwork, and other graphics where fine detail is crucial. On the other hand, laser printers usually have lower maximum resolutions, typically around 1200 DPI, but they excel in producing sharp, clear text and monochrome images due to their precise toner application. In terms of detail, inkjet printers use a combination of ink droplet size and placement to achieve high levels of detail. They can produce a wide range of colors and subtle gradations, making them well-suited for color printing tasks such as brochures, posters, and photo albums. Laser printers, however, rely on toner particles that are fused onto the paper to create images. While they may not match the color detail of inkjet printers, they are unparalleled in their ability to produce consistent, high-quality text with minimal feathering or bleeding. The versatility in resolution and detail also extends to the types of media each printer can handle. Inkjet printers are often more flexible in this regard, capable of printing on various paper types including glossy photo paper, cardstock, and even fabric. This versatility makes them a favorite among creative professionals and hobbyists who need to print a variety of materials. Laser printers, while generally limited to standard office paper and possibly some specialty papers like cardstock or labels, offer superior durability and resistance to fading over time due to the toner's bonding process. In summary, the choice between an inkjet and a laser printer largely depends on your specific needs regarding resolution and detail. If you prioritize vibrant colors and fine details for tasks like photo printing or graphic design, an inkjet printer is likely your best bet. For high-quality text output and monochrome printing with excellent durability, a laser printer is the way to go. Understanding these differences helps you make an informed decision that aligns with your printing requirements and ensures optimal print quality and versatility.

Color Accuracy and Vibrancy

When it comes to print quality and versatility, one of the critical factors to consider is color accuracy and vibrancy. This aspect is particularly important for users who require precise and vivid color reproduction, such as graphic designers, photographers, and businesses that rely on high-quality marketing materials. Inkjet printers generally excel in this area due to their ability to produce a wider gamut of colors. Unlike laser printers, which use toner to create images, inkjet printers utilize liquid ink that can be precisely controlled to achieve more nuanced and vibrant color outputs. This results in prints with deeper blacks, richer colors, and smoother gradients, making them ideal for applications where visual impact is paramount. In contrast, laser printers, while excellent for text and monochrome prints, often struggle to match the color accuracy and vibrancy of inkjet printers. Laser technology relies on toner particles that are fused onto the paper, which can lead to a more limited color range and less precise control over color distribution. However, advancements in laser technology have led to the development of high-end models that can produce respectable color outputs, though they still may not fully match the capabilities of top-tier inkjet printers. The difference in color accuracy and vibrancy between inkjet and laser printers is also influenced by the type of paper used. Inkjet printers can take full advantage of specialized photo papers designed to enhance color saturation and clarity, further amplifying their vibrancy. On the other hand, laser printers may not benefit as much from these papers due to their toner-based printing process. For users who prioritize color accuracy and vibrancy, such as those in creative fields or marketing departments, inkjet printers are typically the better choice. However, for those who primarily need high-quality text prints or monochrome documents, laser printers remain a superior option due to their speed, efficiency, and cost-effectiveness in these areas. Ultimately, understanding the strengths and weaknesses of each printing technology allows users to make informed decisions based on their specific needs and requirements.

Media Compatibility and Specialized Printing

When it comes to print quality and versatility, one crucial aspect to consider is media compatibility and specialized printing. Both inkjet and laser printers have their own strengths and limitations in this regard. Inkjet printers are highly versatile when it comes to media compatibility, allowing users to print on a wide range of materials including glossy paper, matte paper, cardstock, canvas, and even fabric. This versatility makes them ideal for creative projects such as photo printing, art reproductions, and custom crafts. Additionally, inkjet printers can handle various paper sizes and types, making them suitable for both standard documents and specialized prints like posters and banners. On the other hand, laser printers are generally more limited in their media compatibility but excel in specific areas. They are best suited for printing on standard office paper and cardstock, producing crisp text and sharp graphics. While they can handle some specialty papers like glossy or matte finishes, they are not as adaptable as inkjet printers when it comes to non-traditional materials. However, laser printers are unmatched in their ability to produce high-quality text documents at high speeds, making them a staple in office environments. Specialized printing is another area where these two types of printers differ significantly. Inkjet printers are capable of producing high-quality photographic prints with vibrant colors and fine details, thanks to their ability to lay down tiny droplets of ink precisely. This makes them a favorite among photographers and artists who require detailed color accuracy. Some inkjet models also offer specialized features like CD/DVD printing and direct-to-fabric printing, further expanding their creative possibilities. Laser printers, while not as adept at photographic prints, excel in other specialized areas such as high-volume document printing and label creation. They can produce large quantities of text-based documents quickly and efficiently, making them invaluable for businesses that need to print reports, invoices, and other office materials regularly. Some laser models also support envelope printing and custom label creation, which can be particularly useful for marketing and mailing campaigns. In summary, media compatibility and specialized printing are key factors that distinguish inkjet from laser printers. Inkjet printers offer greater versatility in terms of the types of materials they can handle and excel in creative projects requiring high-quality color prints. Laser printers, though more limited in media compatibility, are superior in high-speed text document production and specialized tasks like label creation. Understanding these differences is essential for choosing the right printer based on your specific needs and applications.