What Does A Knock Sensor Do

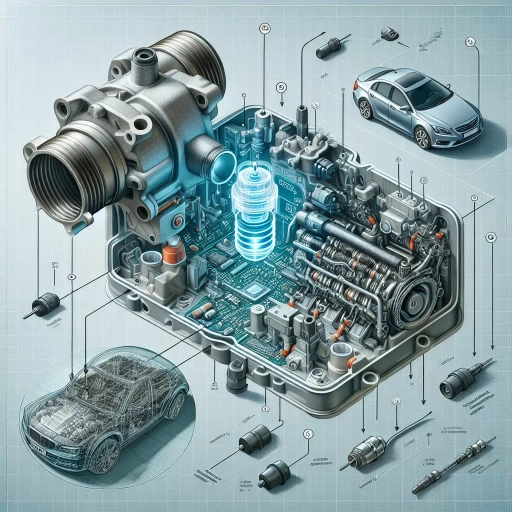

In the intricate world of automotive engineering, several components work in harmony to ensure the optimal performance and longevity of a vehicle's engine. Among these, the knock sensor plays a crucial role. This article delves into the multifaceted function of a knock sensor, exploring its role, operation, and significance. First, we will **understand the role of a knock sensor**, highlighting its primary function within the engine system. Next, we will **examine how a knock sensor works**, detailing the mechanisms and technologies that enable it to detect engine knock or pinging. Finally, we will discuss the **importance and benefits of a knock sensor**, outlining how it contributes to engine health, fuel efficiency, and overall vehicle reliability. By understanding these aspects, drivers and mechanics alike can appreciate the vital contribution of this often-overlooked component. Let's begin by **understanding the role of a knock sensor**.

Understanding the Role of a Knock Sensor

Understanding the role of a knock sensor is crucial for maintaining the health and efficiency of your vehicle's engine. This component plays a pivotal role in three key areas: detecting engine knock or pinging, preventing engine damage, and optimizing engine performance. By detecting engine knock or pinging, the knock sensor helps identify premature ignition of fuel in the combustion chamber, which can lead to serious engine problems if left unchecked. Preventing engine damage is another critical function, as it ensures that the engine operates within safe parameters to avoid costly repairs. Additionally, the knock sensor contributes to optimizing engine performance by allowing the engine control unit to adjust ignition timing and fuel mixture for optimal power output and fuel efficiency. In this article, we will delve into each of these aspects, starting with the essential task of detecting engine knock or pinging.

1. Detecting Engine Knock or Pinging

Detecting engine knock or pinging is a critical function that ensures the longevity and efficiency of an internal combustion engine. Engine knock, also known as pinging or pinking, occurs when the fuel-air mixture in the engine's cylinders ignites prematurely, before the spark plug fires. This premature ignition can cause a knocking or pinging sound and can lead to serious engine damage if left unchecked. The knock sensor plays a pivotal role in detecting this phenomenon. Located on the engine block, the knock sensor is a piezoelectric device that converts the vibrations caused by engine knock into electrical signals. These signals are then sent to the engine control module (ECM), which interprets them to determine if engine knock is occurring. If the ECM detects knock, it adjusts the ignition timing to prevent further damage. This adjustment typically involves retarding the ignition timing slightly to ensure that the fuel-air mixture ignites at the correct time, thus preventing premature ignition and the associated knocking sound. The knock sensor's sensitivity allows it to detect even slight variations in engine vibrations, making it an essential component for maintaining optimal engine performance. Without a functioning knock sensor, an engine could suffer from chronic knocking, leading to overheating, reduced power output, and potentially catastrophic damage such as piston failure or cylinder wall scoring. In modern vehicles, the knock sensor works in conjunction with other advanced technologies like fuel injection systems and variable valve timing to optimize engine performance while minimizing the risk of engine knock. By continuously monitoring engine vibrations and reporting any anomalies to the ECM, the knock sensor helps in fine-tuning the engine's operation to achieve better fuel efficiency, reduced emissions, and enhanced overall reliability. In summary, detecting engine knock or pinging is crucial for preventing engine damage and ensuring optimal performance. The knock sensor is instrumental in this process by detecting vibrations indicative of knock and prompting the ECM to adjust ignition timing accordingly. This synergy between the knock sensor and other engine management systems underscores the importance of this component in maintaining a healthy and efficient engine.

2. Preventing Engine Damage

Preventing engine damage is a critical aspect of maintaining a vehicle's longevity and performance, and the knock sensor plays a pivotal role in this process. Engine knock, also known as pinging or pinking, occurs when the fuel-air mixture in the engine ignites too quickly, causing a knocking or clunking sound. This premature ignition can lead to severe engine damage over time, including piston damage, cylinder wall scoring, and even engine failure. The knock sensor, typically located on the engine block or cylinder head, detects these abnormal combustion patterns and sends a signal to the engine control module (ECM). The ECM then adjusts the ignition timing to prevent further knocking, thereby safeguarding the engine from potential harm. By continuously monitoring engine vibrations, the knock sensor ensures that the fuel-air mixture ignites at the optimal time, preventing excessive heat buildup and stress on engine components. This proactive measure not only protects against immediate damage but also helps maintain fuel efficiency and overall engine health. In modern vehicles, advanced knock sensors are often integrated with sophisticated engine management systems, allowing for real-time adjustments that optimize engine performance while minimizing the risk of damage. Moreover, the knock sensor's ability to detect even slight variations in engine operation enables early detection of potential issues. For instance, if the sensor detects consistent knocking, it may indicate problems such as low-octane fuel use, faulty spark plugs, or clogged fuel injectors. Addressing these issues promptly can prevent more severe damage and costly repairs down the line. In summary, the knock sensor is an essential component in preventing engine damage by ensuring proper combustion timing and alerting the ECM to make necessary adjustments, thus safeguarding the engine's integrity and extending its lifespan.

3. Optimizing Engine Performance

Optimizing engine performance is a multifaceted process that involves several key components, with the knock sensor playing a crucial role. A knock sensor, also known as a detonation sensor, is designed to detect engine knocking or pinging, which occurs when the fuel-air mixture in the engine ignites prematurely. This premature ignition can lead to engine damage over time. To optimize engine performance, it is essential to understand how the knock sensor functions and how it contributes to overall engine health. Firstly, the knock sensor monitors the engine's combustion process. It is typically mounted on the engine block and uses piezoelectric materials to detect vibrations caused by engine knocking. When the sensor detects these vibrations, it sends a signal to the engine control unit (ECU), which then adjusts the ignition timing to prevent further knocking. This real-time adjustment ensures that the engine operates within safe parameters, preventing potential damage. Secondly, optimizing engine performance involves maintaining proper fuel quality and ensuring that the fuel-air mixture is correctly balanced. The knock sensor helps in this regard by providing feedback that allows the ECU to fine-tune fuel injection and ignition timing. For instance, if the fuel used is of lower octane than recommended, it may cause more frequent knocking. The knock sensor's feedback enables the ECU to adjust ignition timing accordingly, mitigating potential issues. Thirdly, regular maintenance is critical for optimizing engine performance. This includes checking and replacing the knock sensor if it becomes faulty. A malfunctioning knock sensor can lead to incorrect readings, causing the ECU to make suboptimal adjustments that could degrade engine performance or even cause damage. Additionally, ensuring that other engine components such as spark plugs, fuel injectors, and oxygen sensors are in good condition helps in maintaining optimal engine performance. In summary, optimizing engine performance relies heavily on the accurate functioning of the knock sensor. By detecting and reporting engine knocking, this sensor allows the ECU to make necessary adjustments to prevent damage and ensure efficient operation. Proper fuel management, regular maintenance, and ensuring all engine components are in good working order are also vital for achieving optimal engine performance. The knock sensor's role is pivotal in this process, making it an indispensable component of modern engine management systems.

How a Knock Sensor Works

A knock sensor is a crucial component in modern vehicle engines, designed to optimize performance and prevent damage. This sensor plays a pivotal role in maintaining the health and efficiency of the engine by monitoring and responding to specific conditions. Here’s how it works: the knock sensor **senses vibration and pressure changes** within the engine, which are indicative of potential issues such as engine knocking or pinging. Once these vibrations are detected, the sensor **sends signals to the Engine Control Unit (ECU)**, which then interprets these signals to determine the appropriate course of action. Based on this information, the ECU **adjusts fuel injection and ignition timing** to prevent engine damage and ensure smooth operation. By understanding how a knock sensor functions, we can appreciate its importance in maintaining engine longevity and performance. Let's delve deeper into the first critical step: **sensing vibration and pressure changes**.

1. Sensing Vibration and Pressure Changes

Sensing vibration and pressure changes is a critical function of a knock sensor, which plays a pivotal role in maintaining the health and efficiency of an internal combustion engine. A knock sensor, typically a piezoelectric device, is designed to detect the subtle vibrations and pressure fluctuations that occur within the engine's combustion chamber. When fuel ignites too quickly or under high pressure, it can cause engine knocking or pinging, which can lead to serious damage over time. The knock sensor is strategically mounted on the engine block to capture these vibrations accurately. The sensor works by converting mechanical stress into an electrical signal. When the engine experiences knocking, the sensor detects the unique frequency and amplitude of these vibrations. This information is then transmitted to the engine control unit (ECU), which interprets the signal and adjusts the ignition timing accordingly. By retarding the ignition timing, the ECU can prevent further knocking and protect the engine from potential damage. The precision of the knock sensor is crucial because it must distinguish between normal engine noise and the specific vibrations associated with knocking. Advanced knock sensors often use sophisticated algorithms to filter out irrelevant signals and ensure accurate detection. This ensures that the ECU receives reliable data, enabling it to make precise adjustments to maintain optimal engine performance and longevity. In modern vehicles, knock sensors are often integrated with other engine management systems to provide real-time feedback and continuous monitoring. This integration allows for dynamic adjustments to be made based on various operating conditions, such as load, speed, and temperature. By continuously sensing and responding to changes in engine vibrations and pressure, the knock sensor helps in optimizing fuel efficiency, reducing emissions, and enhancing overall engine reliability. In summary, the ability of a knock sensor to sense vibration and pressure changes is essential for preventing engine damage and ensuring smooth operation. Through its precise detection and real-time communication with the ECU, the knock sensor plays a vital role in maintaining the health and performance of modern internal combustion engines.

2. Sending Signals to the Engine Control Unit (ECU)

When a knock sensor detects engine knocking or pinging, it sends critical signals to the Engine Control Unit (ECU) to prevent potential engine damage. Here’s how this process works: The knock sensor, typically a piezoelectric sensor, is mounted on the engine block and is designed to detect the high-frequency vibrations that occur when fuel ignites too quickly, causing engine knocking. When these vibrations are detected, the sensor converts them into electrical signals. These signals are then transmitted to the ECU, which is the central computer of the vehicle responsible for managing engine performance. Upon receiving these signals, the ECU interprets them as indicative of engine knocking and immediately takes corrective action. The primary response is to adjust the ignition timing. By retarding the ignition timing, the ECU ensures that fuel ignites later in the combustion cycle, reducing the likelihood of premature ignition and thus mitigating engine knocking. Additionally, the ECU may also adjust fuel injection timing and air/fuel mixture to further stabilize combustion and prevent knocking. These adjustments are made in real-time, ensuring that engine performance is optimized while protecting against potential damage from knocking. In modern vehicles, this communication between the knock sensor and ECU is instantaneous and continuous, allowing for precise control over engine operations. This dynamic interaction is crucial for maintaining engine health, improving fuel efficiency, and enhancing overall vehicle performance. By sending accurate and timely signals to the ECU, the knock sensor plays a vital role in preventing engine damage and ensuring smooth operation under various driving conditions.

3. Adjusting Fuel Injection and Ignition Timing

Adjusting fuel injection and ignition timing is a critical process that directly impacts the performance and efficiency of an internal combustion engine. When a knock sensor detects engine knocking or pinging, which is indicative of premature fuel ignition, the engine control unit (ECU) responds by making necessary adjustments to prevent damage. Here’s how it works: 1. **Fuel Injection Adjustment**: The ECU can adjust the timing and amount of fuel injected into the cylinders. If knocking is detected, the ECU may delay the fuel injection timing slightly to ensure that the fuel-air mixture ignites at the correct moment, reducing the likelihood of premature ignition. This adjustment helps in maintaining optimal combustion conditions and prevents engine damage from excessive knocking. 2. **Ignition Timing Adjustment**: Ignition timing refers to the moment when the spark plug ignites the fuel-air mixture in the cylinder. When a knock sensor detects knocking, the ECU can retard (delay) the ignition timing to prevent the fuel from igniting too early. By delaying ignition, the ECU ensures that combustion occurs closer to the optimal timing, thus reducing stress on engine components and preventing potential damage. 3. **Dynamic Adjustments**: Modern engines often employ sophisticated systems that allow for dynamic adjustments based on real-time data from various sensors, including knock sensors. These systems can continuously monitor engine conditions and make fine-tuned adjustments to fuel injection and ignition timing as needed. This ensures that the engine operates within safe parameters while maintaining optimal performance and efficiency. In summary, adjusting fuel injection and ignition timing in response to knock sensor data is essential for preventing engine knocking and ensuring smooth, efficient operation. By making these adjustments, the ECU helps protect the engine from potential damage while optimizing its performance under varying operating conditions. This process underscores the critical role that knock sensors play in modern engine management systems, enabling engines to run reliably and efficiently over their lifespan.

Importance and Benefits of a Knock Sensor

The knock sensor is a crucial component in modern vehicle engines, offering a multitude of benefits that enhance overall performance, sustainability, and longevity. By monitoring engine knock or pinging, this sensor helps in optimizing fuel efficiency, reducing emissions and environmental impact, and extending the lifespan of the engine. Enhancing fuel efficiency is one of the primary advantages, as it allows the engine to run at its optimal performance without wasting fuel. Reducing emissions is another significant benefit, as it helps in minimizing the release of harmful pollutants into the atmosphere. Additionally, by preventing engine knock, the sensor plays a vital role in extending the engine's lifespan by reducing wear and tear on critical components. In this article, we will delve into these key areas, starting with how the knock sensor enhances fuel efficiency. By understanding how this sensor operates and its impact on fuel consumption, we can appreciate its importance in maintaining a healthy and efficient engine.

1. Enhancing Fuel Efficiency

Enhancing fuel efficiency is a critical aspect of modern automotive technology, and the knock sensor plays a pivotal role in this endeavor. By detecting engine knock or pinging, which occurs when fuel ignites prematurely in the combustion chamber, the knock sensor helps the engine control unit (ECU) to adjust ignition timing and prevent potential damage. This real-time monitoring ensures that the engine operates within optimal parameters, thereby improving fuel efficiency. When an engine experiences knock, it can lead to reduced performance and increased fuel consumption. The knock sensor, typically located on the engine block or cylinder head, detects these abnormal combustion patterns through vibrations and sends signals to the ECU. In response, the ECU adjusts the ignition timing to prevent further knocking, which not only protects the engine from damage but also maintains a stable and efficient combustion process. This adjustment is crucial because it allows the engine to run at its most efficient state without compromising power output. For instance, if an engine is prone to knocking due to low-octane fuel or other factors, the knock sensor's feedback enables the ECU to retard the ignition timing slightly, preventing knock while still optimizing fuel burn. This results in better mileage and lower emissions, contributing significantly to overall fuel efficiency. Moreover, a well-functioning knock sensor ensures that the engine can operate with a higher compression ratio, which is directly linked to better fuel efficiency. Higher compression ratios allow for more efficient combustion of fuel, leading to improved power output and reduced fuel consumption. However, without a knock sensor to monitor and adjust for any knocking issues, running at higher compression ratios could be detrimental to the engine's health. In addition to these technical benefits, enhancing fuel efficiency through the use of a knock sensor also has economic and environmental advantages. By optimizing engine performance and reducing fuel consumption, vehicle owners can save on fuel costs over time. Furthermore, lower fuel consumption translates into reduced greenhouse gas emissions, contributing to a cleaner environment and compliance with increasingly stringent emissions regulations. In summary, the knock sensor is an indispensable component in enhancing fuel efficiency by ensuring that the engine operates within safe and optimal parameters. Its ability to detect and prevent engine knock allows for more efficient combustion processes, higher compression ratios, and ultimately better mileage and lower emissions. This not only benefits vehicle owners economically but also supports broader environmental goals by reducing fuel consumption and emissions.

2. Reducing Emissions and Environmental Impact

Reducing emissions and environmental impact is a critical aspect of modern automotive technology, and the knock sensor plays a pivotal role in this endeavor. By monitoring engine knock or pinging, which occurs when fuel ignites prematurely in the combustion chamber, the knock sensor helps optimize engine performance and efficiency. Here’s how it contributes to a more environmentally friendly vehicle: 1. **Optimized Fuel Efficiency**: The knock sensor ensures that the engine operates within its optimal parameters, preventing excessive fuel consumption. When the sensor detects knock, it signals the engine control unit (ECU) to adjust ignition timing, thereby preventing damage and maintaining fuel efficiency. This optimization reduces overall fuel consumption, which in turn lowers greenhouse gas emissions. 2. **Minimized Emissions**: Efficient engine operation directly correlates with reduced emissions. By preventing knock, the sensor helps maintain proper combustion processes, which minimizes the production of harmful pollutants such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx). These pollutants are significant contributors to air pollution and climate change. 3. **Extended Engine Life**: Knock can lead to engine damage over time, necessitating costly repairs or even replacement. By preventing knock, the sensor extends the lifespan of the engine, reducing the need for frequent replacements and the associated environmental impact of manufacturing new engines. 4. **Enhanced Performance**: A well-functioning knock sensor ensures that the engine runs smoothly and efficiently, providing better performance without compromising on emissions. This balance between performance and environmental responsibility is crucial for modern vehicles aiming to meet stringent emissions standards. 5. **Compliance with Regulations**: Many countries have implemented strict emissions regulations to combat environmental degradation. The knock sensor helps vehicles comply with these regulations by ensuring that engines operate within specified parameters, thereby reducing emissions and environmental impact. In summary, the knock sensor is an essential component in reducing emissions and environmental impact by optimizing fuel efficiency, minimizing harmful emissions, extending engine life, enhancing performance, and aiding compliance with emissions regulations. Its role underscores the importance of advanced automotive technologies in mitigating environmental challenges.

3. Extending Engine Lifespan

Extending engine lifespan is a critical benefit of incorporating a knock sensor into your vehicle's engine management system. A knock sensor, also known as a detonation sensor, plays a pivotal role in preventing engine damage by detecting the early signs of engine knocking or pinging. Engine knocking occurs when the fuel-air mixture in the cylinders ignites prematurely, causing a knocking or pinging sound. This phenomenon can lead to severe engine damage if left unchecked, including piston damage, cylinder head damage, and even engine failure. The knock sensor works by monitoring the vibrations within the engine block and sending signals to the engine control unit (ECU) when it detects abnormal combustion patterns. The ECU then adjusts the ignition timing to prevent further knocking, thereby protecting the engine from potential harm. By continuously monitoring and adjusting for these conditions, the knock sensor ensures that the engine operates within safe parameters, reducing wear and tear on critical components. Regular use of a knock sensor can significantly extend engine lifespan in several ways. Firstly, it prevents the cumulative damage caused by repeated knocking events, which can weaken engine components over time. Secondly, it allows for more efficient fuel combustion, which reduces stress on the engine and its components. This efficiency also translates into better fuel economy and lower emissions, making it an environmentally friendly choice as well. Moreover, a knock sensor enables the use of higher compression ratios and more aggressive ignition timing without risking engine damage. This means that engines can be tuned for better performance without compromising on durability. In modern vehicles, where engines are often pushed to their limits for optimal performance and efficiency, the presence of a knock sensor is indispensable for maintaining long-term reliability. In summary, the knock sensor is an essential component for extending engine lifespan by preventing engine knocking, ensuring efficient combustion, and allowing for more aggressive engine tuning. Its continuous monitoring and real-time adjustments safeguard the engine against potential damage, leading to a longer and healthier engine life. This underscores the importance and benefits of a knock sensor in modern automotive technology.