What Is Satin Made Of

Satin, a fabric renowned for its luxurious feel and elegant appearance, has been a staple in high-end fashion and home decor for centuries. But what exactly is satin made of, and how does it achieve its distinctive sheen and smooth texture? To fully appreciate the allure of satin, it is essential to delve into its composition, production process, and historical significance. This article will explore the materials used in satin production, revealing the various fibers that contribute to its unique properties. We will also examine the intricate manufacturing process that transforms these raw materials into the exquisite fabric we know and love. By understanding these elements, we can gain a deeper appreciation for the craftsmanship and technology behind satin. Let us begin by introducing the fascinating world of satin fabric, uncovering its origins and characteristics that have made it a timeless favorite among designers and consumers alike. **Introduction to Satin Fabric**

Introduction to Satin Fabric

Satin fabric, renowned for its luxurious texture and lustrous appearance, has been a staple in the world of textiles for centuries. This versatile material has captivated designers, artisans, and consumers alike with its unique blend of elegance and durability. To fully appreciate the significance of satin, it is essential to delve into its rich historical background, which spans across various cultures and eras. Understanding the evolution of satin provides a deeper insight into its craftsmanship and enduring appeal. Additionally, exploring the diverse types of satin fabrics available today highlights the material's adaptability and range, from traditional charmeuse to modern variations. Finally, examining the common uses of satin reveals its widespread application in fashion, home decor, and other industries, showcasing its practical as well as aesthetic value. By exploring these facets, we can gain a comprehensive understanding of what makes satin such a cherished and versatile fabric, leading us to a thorough introduction to satin fabric.

Historical Background of Satin

**Historical Background of Satin** Satin, a fabric renowned for its luxurious sheen and smooth texture, has a rich and storied history that spans centuries. The origins of satin date back to the Middle Ages, specifically to the 12th century in China during the Song Dynasty. Here, skilled artisans developed intricate weaving techniques that allowed them to create fabrics with a unique glossy appearance. This early form of satin was highly prized for its beauty and durability, making it a staple in royal garments and ceremonial attire. As trade routes expanded, satin began to spread throughout Asia and eventually into Europe via the Silk Road. By the 14th century, Italian weavers in cities like Florence and Venice had mastered the art of satin production, incorporating it into their renowned textile industry. The fabric quickly gained popularity among European nobility, who valued its opulence and versatility. During the Renaissance, satin became a symbol of wealth and status, adorning the garments of monarchs and aristocrats alike. The 18th and 19th centuries saw significant advancements in textile technology, which further democratized satin production. New weaving machines and improved manufacturing processes made satin more accessible to a broader audience, though it remained a luxury item due to its high production costs. This period also witnessed the development of various satin types, such as charmeuse and habotai, each with its own distinct characteristics but all retaining the signature luster that defined satin. In modern times, satin continues to be celebrated for its aesthetic appeal and functional qualities. Advances in synthetic fibers have led to the creation of blended satins that offer enhanced durability without compromising on appearance. Today, satin is used not only in high-end fashion but also in home decor, upholstery, and even medical applications due to its smooth surface and ease of cleaning. Throughout its history, satin has remained a fabric of distinction, symbolizing elegance and sophistication. From its ancient origins in China to its widespread use today, satin has evolved while retaining its timeless allure. Its enduring popularity is a testament to the ingenuity of textile artisans and the enduring appeal of this exquisite fabric. As we delve into what satin is made of, understanding its historical background provides a deeper appreciation for the craftsmanship and innovation that have shaped this beloved material over centuries.

Types of Satin Fabrics

Satin fabrics are renowned for their luxurious feel, smooth texture, and lustrous appearance, making them a staple in high-end fashion and home decor. There are several types of satin fabrics, each with its own unique characteristics and uses. **Duchess Satin**, often considered the most luxurious, is made from high-quality silk or synthetic fibers. It is known for its dense weave and exceptional smoothness, making it ideal for evening wear and formal gowns. **Charmeuse Satin**, another popular variant, features a soft, lightweight construction with a smooth face and a slightly rougher back. This type is commonly used in lingerie, nightwear, and other intimate apparel due to its comfort and drape. **Satin Twill**, as the name suggests, combines the twill weave with the satin weave technique. This fabric has a diagonal ribbing effect and is more durable than traditional satin. It is often used in upholstery and home furnishings where both aesthetics and durability are crucial. **Stretch Satin** incorporates elastane or spandex into its weave, providing flexibility and stretchiness. This type is favored in activewear, dancewear, and other garments that require both comfort and style. **Matte Satin**, also known as **Dull Satin**, lacks the sheen of traditional satin but retains its smooth texture. It is preferred when a more subtle look is desired and is commonly used in casual wear and accessories. **Jacquard Satin** features intricate designs woven directly into the fabric using a jacquard loom. This type is highly prized for its detailed patterns and is often used in bespoke clothing and decorative textiles. **Habotai Satin**, originating from Japan, is a lightweight silk fabric with a soft, smooth texture. It is versatile and can be used in various applications from kimonos to home decor items. **Dupioni Satin**, made from silk or synthetic fibers, has a unique texture with small slubs that give it an iridescent sheen. This fabric is popular in evening wear and formal events due to its eye-catching appearance. Understanding these different types of satin fabrics allows consumers to make informed choices based on their specific needs—whether it's for fashion, home decor, or other textile applications. Each type offers distinct advantages in terms of durability, comfort, and aesthetic appeal, ensuring that there is a satin fabric suitable for any project or occasion. By selecting the right type of satin fabric, individuals can ensure that their creations exude elegance, sophistication, and quality.

Common Uses of Satin

Satin fabric, renowned for its luxurious feel and lustrous appearance, has a wide range of applications across various industries. One of the most common uses of satin is in the fashion industry, where it is highly prized for its elegance and versatility. Satin is often used in evening wear, such as gowns, cocktail dresses, and formal suits, due to its ability to create a sophisticated and glamorous look. Its smooth surface and drape make it ideal for creating flowing silhouettes that catch the light beautifully. Additionally, satin is frequently incorporated into bridal wear, including wedding dresses and veils, to add an element of opulence and romance. Beyond high-end fashion, satin also plays a significant role in home decor. It is used in upholstery for furniture, particularly in luxurious settings like hotels and high-end residences, where its sheen and durability are valued. Satin can also be found in bedding and linens, such as duvets, pillowcases, and tablecloths, where it adds a touch of luxury and sophistication to any room. The fabric's smooth texture makes it easy to clean and maintain, further enhancing its appeal for home furnishings. In the realm of textiles and crafts, satin is a favorite among quilters and sewists due to its smooth weave and ease of handling. It is often used in quilting projects where a high level of precision is required, as well as in making decorative items like pillow covers, wall hangings, and other home decor accents. Satin's luster also makes it a popular choice for ribbon-making and other craft projects that require a touch of elegance. Furthermore, satin has practical applications in various other fields. In medical settings, satin is sometimes used in the production of medical garments and equipment due to its smooth surface which can reduce friction and prevent skin irritation. In sports apparel, particularly in figure skating and dance costumes, satin's stretchy properties combined with its aesthetic appeal make it an ideal choice for performance wear. Lastly, satin's unique properties make it a staple in theatrical and performance arts. It is commonly used in stage costumes for its ability to catch light and create dramatic effects under stage lighting. The fabric's drape and flow also make it perfect for creating elaborate costumes that need to move fluidly with the performer. In summary, satin's versatility extends far beyond its luxurious appearance; it offers a blend of functionality, durability, and aesthetic appeal that makes it a valuable material across multiple industries and applications. Whether in high fashion, home decor, crafts, or performance arts, satin continues to be a sought-after fabric for its unique combination of beauty and practicality.

Materials Used in Satin Production

Satin, a fabric renowned for its smooth, lustrous surface and elegant drape, has been a staple in high-end fashion and interior design for centuries. The allure of satin lies not only in its aesthetic appeal but also in the diverse range of materials used in its production. This article delves into the various fibers that contribute to the unique characteristics of satin, exploring three primary categories: natural fibers such as silk and cotton, synthetic fibers like polyester and nylon, and blends that combine the best qualities of both natural and synthetic materials. By understanding these different fibers, readers will gain a deeper appreciation for the craftsmanship and versatility behind satin fabric. Whether you are a fashion enthusiast, a textile professional, or simply someone interested in the intricacies of fabric production, this exploration will provide valuable insights into what makes satin so distinctive. Let us begin our journey into the world of satin by examining the foundational elements that define this luxurious fabric. **Introduction to Satin Fabric**

Natural Fibers: Silk and Cotton

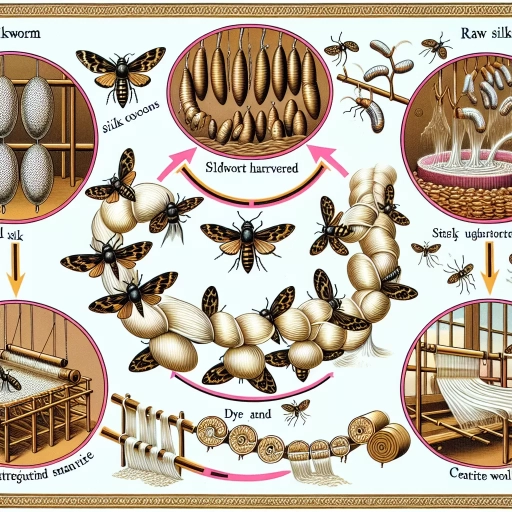

Natural fibers, particularly silk and cotton, play a pivotal role in the production of satin, a luxurious and smooth fabric known for its lustrous appearance and soft texture. **Silk**, derived from the cocoons of silkworms, is one of the most prized natural fibers due to its exceptional strength, elasticity, and sheen. The process of harvesting silk involves unwinding the cocoons, which are then spun into yarns. Silk's unique properties make it an ideal choice for satin production: it offers a natural sheen that enhances the fabric's visual appeal, while its smooth surface ensures a silky touch. Additionally, silk's breathability and moisture-wicking capabilities contribute to the comfort and durability of satin fabrics. **Cotton**, on the other hand, is a more versatile and widely used natural fiber. Obtained from the cotton plant, cotton fibers are known for their softness, absorbency, and ease of care. While cotton is not as inherently lustrous as silk, it can be woven in such a way that mimics the smoothness and shine of satin. Cotton satin, often referred to as "faux satin," is a more affordable alternative to silk satin and still offers a luxurious feel. The weaving technique used in cotton satin involves a specific type of weave that creates a smooth, glossy surface on one side of the fabric while maintaining a more textured underside. This method allows cotton to emulate the aesthetic qualities of silk satin without the high cost. Both silk and cotton satins are highly valued for their unique characteristics. Silk satin is often used in high-end fashion and home decor due to its luxurious feel and appearance. It is particularly favored for evening wear, lingerie, and bedding because of its opulence and comfort. Cotton satin, while less luxurious than its silk counterpart, is still a popular choice for everyday garments and home textiles due to its affordability and practicality. It is commonly used in dresses, blouses, and upholstery where a touch of elegance is desired without the hefty price tag. In summary, natural fibers like silk and cotton are essential components in the production of satin fabrics. Silk brings an unparalleled level of luxury with its natural sheen and smooth texture, making it ideal for high-end applications. Cotton, with its versatility and affordability, offers a more accessible alternative that still captures the essence of satin's luxurious appeal. Together, these fibers enable the creation of satin fabrics that are not only visually stunning but also comfortable and durable.

Synthetic Fibers: Polyester and Nylon

Synthetic fibers, particularly polyester and nylon, play a significant role in the production of satin fabrics, offering a blend of durability, versatility, and aesthetic appeal. **Polyester**, one of the most widely used synthetic fibers, is renowned for its strength, resistance to wrinkles, and ease of care. It can be woven into a variety of textures and weaves, making it an ideal choice for satin production. Polyester satin fabrics are often preferred for their affordability and ability to mimic the luxurious feel of natural fibers like silk. Additionally, polyester can be treated with various finishes to enhance its softness and luster, further elevating the satin's appearance. Its resistance to shrinkage and fading ensures that polyester satin retains its quality over time, making it a popular choice for both high-end and mass-market applications. **Nylon**, another prominent synthetic fiber, is known for its exceptional strength, elasticity, and resistance to abrasion. While less commonly used in satin production compared to polyester, nylon can add unique properties that enhance the fabric's performance. Nylon satin fabrics are particularly valued for their resilience and ability to withstand heavy use, making them suitable for applications where durability is paramount. The fiber's moisture-wicking properties also contribute to a comfortable wear experience, especially in garments that require both style and functionality. However, nylon satin may lack the softness and drape of polyester or natural fibers, which can affect its overall aesthetic appeal. Despite this, advancements in textile technology have allowed for the development of softer nylon blends that mitigate these drawbacks. The integration of polyester and nylon into satin production allows manufacturers to balance cost, performance, and aesthetics effectively. These synthetic fibers can be blended with other materials to create hybrid fabrics that leverage the best qualities of each component. For instance, a blend of polyester and nylon can offer enhanced strength and durability while maintaining a smooth, lustrous finish characteristic of satin. This versatility makes synthetic fibers indispensable in modern textile manufacturing, enabling the creation of high-quality satin fabrics that cater to diverse needs and preferences. Whether used in fashion garments, home decor, or industrial applications, polyester and nylon continue to be essential components in the production of satin, ensuring that this luxurious fabric remains accessible and desirable across various markets.

Blends: Combining Natural and Synthetic Fibers

In the realm of textile production, particularly in the creation of satin, the concept of blends—combining natural and synthetic fibers—plays a pivotal role in enhancing fabric performance and versatility. Satin, known for its smooth, lustrous surface and soft drape, can benefit significantly from the integration of different fiber types. Natural fibers such as silk, cotton, and linen offer inherent advantages like breathability, comfort, and a natural aesthetic. However, they can be prone to wrinkles, shrinkage, and limited durability. On the other hand, synthetic fibers like polyester, nylon, and spandex provide strength, resistance to wrinkles, and ease of care but may lack the luxurious feel and breathability of their natural counterparts. By blending these fibers, manufacturers can create satin fabrics that leverage the best qualities of each material. For instance, a blend of silk and polyester can result in a fabric that retains the luxurious sheen and softness of silk while gaining the durability and wrinkle resistance of polyester. Similarly, combining cotton with spandex can enhance the fabric's elasticity and fit without compromising its natural comfort. These blends not only improve the overall performance of satin but also make it more adaptable to various applications, from high-end fashion garments to home textiles. The blending process involves careful consideration of the fiber ratios to achieve the desired balance of properties. Advanced textile technologies allow for precise control over fiber distribution, ensuring that the final product meets specific criteria for texture, strength, and appearance. Additionally, blending can be done at different stages of production, such as during spinning or weaving, allowing for a wide range of possibilities in terms of fabric design and functionality. The benefits of blended fibers extend beyond performance; they also offer environmental and economic advantages. By incorporating recycled synthetic fibers or sustainably sourced natural fibers, manufacturers can reduce the ecological footprint of their products. Furthermore, blending can help optimize production costs by utilizing less expensive synthetic fibers while maintaining the premium appeal associated with natural fibers. In conclusion, the strategic combination of natural and synthetic fibers in satin production is a key factor in creating high-quality fabrics that are both aesthetically pleasing and functionally superior. This approach not only enhances the inherent qualities of satin but also opens up new possibilities for innovation in textile design and manufacturing. As the demand for versatile, sustainable, and high-performance materials continues to grow, the role of blended fibers in satin production will remain crucial in meeting these evolving needs.

Manufacturing Process of Satin

Satin, a fabric renowned for its luxurious feel and lustrous appearance, has been a staple in high-end fashion and home decor for centuries. The manufacturing process of satin is a complex and meticulous journey that involves several critical stages. At the heart of satin production lies the weaving technique, where the satin weave distinguishes itself from other types of weaves through its unique interlacing pattern, creating the fabric's signature smooth and glossy surface. Following the weaving process, the fabric undergoes dyeing and finishing treatments that enhance its color, texture, and durability. These processes are crucial in achieving the desired aesthetic and functional properties of satin. Finally, rigorous quality control measures are implemented to ensure that every piece of satin meets the highest standards of excellence. In this article, we will delve into the intricacies of these stages, exploring the weaving techniques that set satin apart, the dyeing and finishing processes that refine its quality, and the quality control measures that guarantee its excellence. Introduction to Satin Fabric will provide a comprehensive understanding of what makes this fabric so exceptional.

Weaving Techniques: Satin Weave vs. Other Weaves

In the realm of textile manufacturing, weaving techniques play a crucial role in defining the characteristics and quality of fabrics. Among these techniques, satin weave stands out for its unique properties and aesthetic appeal. Unlike other weaves such as plain weave, twill weave, and herringbone weave, satin weave is distinguished by its smooth, lustrous surface and soft texture. Satin weave achieves this by using a specific type of interlacing pattern where the warp yarns float over multiple weft yarns before crossing over one weft yarn, creating long floats on the fabric's surface. This results in a fabric with minimal interlacing points, which reduces friction and gives satin its signature sheen and smoothness. In contrast, plain weave involves a simple over-and-under pattern between warp and weft yarns, producing a more rigid and less shiny fabric. Twill weave, characterized by diagonal lines, offers durability but lacks the luxurious feel of satin. Herringbone weave, with its reversible chevron pattern, provides a balanced texture but does not match satin's luster. The choice of weave significantly impacts the fabric's performance and application. Satin's smooth surface makes it ideal for garments that require elegance and comfort, such as evening wear and lingerie. Its low friction also reduces snagging and pilling, enhancing the fabric's longevity. However, this comes at the cost of reduced durability compared to other weaves like twill or herringbone, which are better suited for heavy-duty applications. Moreover, the manufacturing process of satin involves careful selection of yarns and precise control over the weaving process to ensure that the floats are evenly distributed and the fabric remains stable. This attention to detail is critical because any irregularities can disrupt the fabric's appearance and performance. In summary, while other weaves offer their own advantages in terms of strength and versatility, satin weave's unique interlacing pattern sets it apart as a premium fabric known for its luxurious feel and visual appeal. Understanding these differences is essential for manufacturers aiming to produce high-quality satin fabrics that meet the expectations of discerning consumers.

Dyeing and Finishing Processes

In the manufacturing process of satin, the dyeing and finishing processes are crucial steps that enhance the fabric's aesthetic appeal, durability, and performance. Dyeing involves immersing the fabric in a dye bath to achieve the desired color. For satin, which is typically made from silk or synthetic fibers like polyester, the dyeing process must be carefully controlled to ensure even color distribution and to maintain the fabric's smooth, lustrous surface. The choice of dyeing method—whether it be piece dyeing, yarn dyeing, or solution dyeing—depends on the desired color intensity and uniformity. Piece dyeing, for instance, allows for greater flexibility in achieving complex color patterns and shades. Following dyeing, the finishing processes further refine the fabric's properties. Finishing treatments can include chemical treatments to improve wrinkle resistance, stain repellency, and softness. For satin, a common finishing treatment is calendaring, which involves passing the fabric through heated rollers to enhance its smoothness and sheen. This process aligns the fibers in a uniform direction, contributing to satin's characteristic glossy appearance. Additionally, some satins may undergo napping or sanforizing to prevent shrinkage and improve dimensional stability. Textile manufacturers also employ various specialized finishes to cater to specific market demands. For example, a fabric finisher might apply a fabric softener or a fabric protector to enhance the fabric's tactile qualities and longevity. In the case of satin used in high-end fashion or home decor, additional treatments such as anti-crease or anti-wrinkle finishes can be applied to maintain the fabric's luxurious appearance over time. Moreover, with increasing consumer awareness of sustainability and environmental impact, eco-friendly dyeing and finishing techniques are gaining prominence. These methods involve using natural dyes, reducing water consumption, and minimizing chemical usage. Such practices not only contribute to a greener manufacturing process but also appeal to consumers seeking environmentally responsible products. In summary, the dyeing and finishing processes are integral components of satin production, transforming raw fabric into a luxurious textile with enhanced visual appeal and functional properties. By carefully selecting and applying these treatments, manufacturers can create satin fabrics that meet both aesthetic and performance standards, making them ideal for various applications ranging from high-fashion garments to elegant home furnishings.

Quality Control Measures

In the manufacturing process of satin, quality control measures are paramount to ensure the production of high-quality fabric that meets both aesthetic and functional standards. These measures are integrated at various stages of the manufacturing process to guarantee consistency and excellence. Initially, raw material inspection is crucial; suppliers must provide yarns that meet specific criteria for fiber content, strength, and color consistency. Once the yarns are selected, they undergo rigorous testing for tensile strength, elasticity, and colorfastness to ensure they can withstand the weaving process and subsequent use. During the weaving stage, quality control involves monitoring the loom settings and thread tension to prevent defects such as uneven weaves or broken threads. Regular checks on the fabric's density, weave pattern, and surface smoothness are also conducted to maintain the signature smooth and lustrous finish of satin. Additionally, fabric samples are periodically removed from the production line for detailed inspection under magnification to detect any microscopic flaws. Post-weaving, the fabric undergoes a series of treatments including dyeing, finishing, and washing. Here, quality control focuses on ensuring uniform dye penetration and color stability. Chemical treatments are carefully calibrated to enhance the fabric's softness, wrinkle resistance, and durability without compromising its texture or appearance. Each batch of treated fabric is then inspected for color uniformity, texture consistency, and any signs of chemical damage. Finally, before packaging and distribution, the finished satin fabric undergoes a comprehensive quality check. This includes visual inspections for any visible defects such as snags, runs, or uneven dyeing. The fabric is also subjected to performance tests such as abrasion resistance, shrinkage testing, and lightfastness to ensure it will retain its quality over time. By implementing these stringent quality control measures at every stage of the manufacturing process, manufacturers can guarantee that their satin fabric meets the highest standards of quality, ensuring customer satisfaction and maintaining a reputation for excellence in textile production. This meticulous approach not only enhances the product's performance but also contributes to its luxurious feel and appearance that satin is renowned for.