What Are Brake Pads Made Of

Brake pads are a crucial component of any vehicle's braking system, ensuring safe and efficient stopping. But what exactly are these vital parts made of? Understanding the materials, manufacturing process, and performance characteristics of brake pads is essential for both car enthusiasts and everyday drivers. This article delves into the intricacies of brake pad composition, exploring the diverse range of materials used in their construction. We will examine the various substances that go into making brake pads, from organic compounds to semi-metallic and ceramic materials. Additionally, we will discuss the manufacturing process that transforms these raw materials into functional brake pads. Finally, we will analyze the performance characteristics of different brake pad materials, highlighting their strengths and weaknesses. By grasping these key aspects, readers can make informed decisions about their vehicle's maintenance and safety. Let's begin by looking at the materials used in brake pads, which form the foundation of their functionality and durability.

Materials Used in Brake Pads

When it comes to the critical component of vehicle safety, brake pads, the choice of materials is paramount. Brake pads must balance durability, heat resistance, and frictional performance to ensure reliable braking under various conditions. The industry has developed three primary types of materials for brake pads: Organic, Semi-Metallic, and Ceramic. Each type has its unique characteristics and advantages, catering to different driving needs and preferences. Organic materials, often referred to as non-asbestos organic (NAO) brake pads, are composed of natural fibers like rubber, Kevlar, and other synthetic materials. These pads are known for their quiet operation and smooth braking feel, making them ideal for everyday driving. However, they may not perform as well under high-temperature conditions or heavy loads. Semi-Metallic materials, on the other hand, incorporate metal fibers such as steel wool or iron into their composition. These pads offer superior heat dissipation and durability, making them suitable for heavy-duty applications like trucks and high-performance vehicles. Despite their robustness, semi-metallic pads can be noisier and may cause more wear on the brake rotors. Ceramic materials represent a modern advancement in brake pad technology. These pads combine ceramic fibers with other materials to provide a balance of performance and comfort. They are known for their low dust emission, quiet operation, and consistent braking performance across various temperatures. Ceramic brake pads are a popular choice for passenger vehicles due to their all-around benefits. Understanding the differences between these materials is crucial for selecting the right brake pads for your vehicle. Let's delve deeper into the specifics of each type, starting with Organic Materials.

Organic Materials

Organic materials play a significant role in the composition of brake pads, offering a blend of performance, safety, and environmental considerations. These materials are derived from natural sources and are often combined with synthetic components to enhance their durability and effectiveness. The primary organic components in brake pads include fibers such as Kevlar, cellulose, and other plant-based materials. Kevlar, known for its high strength-to-weight ratio, provides excellent thermal stability and resistance to wear, making it an ideal choice for absorbing heat generated during braking. Cellulose fibers, on the other hand, contribute to the pad's frictional properties and help in maintaining consistent braking performance across various temperatures. In addition to these fibers, organic brake pads may also contain fillers like rubber and resins that bind the mixture together. These fillers help in achieving the desired friction coefficient and ensure that the brake pads adhere well to the rotor surface. The use of organic materials allows for a more controlled release of frictional energy, which can lead to smoother braking and reduced noise levels compared to semi-metallic or fully metallic brake pads. One of the key advantages of organic brake pads is their environmental friendliness. Unlike metallic brake pads that can release harmful metal particles into the atmosphere, organic materials are generally non-toxic and biodegradable. This makes them a preferred choice for vehicles operating in urban areas where air quality is a significant concern. Furthermore, organic brake pads tend to be quieter and produce less dust compared to their metallic counterparts, enhancing overall driving comfort. However, it's important to note that while organic brake pads offer several benefits, they may not be as durable as semi-metallic or fully metallic options. They typically have a shorter lifespan and may require more frequent replacement. This trade-off between performance and longevity must be considered when selecting brake pads for specific applications. In summary, organic materials in brake pads provide a unique set of advantages that cater to both performance and environmental needs. Their ability to offer smooth, quiet braking while minimizing environmental impact makes them an attractive option for many vehicle owners. As technology continues to evolve, we can expect further innovations in organic brake pad materials that balance durability with sustainability.

Semi-Metallic Materials

Semi-metallic materials are a crucial component in the fabrication of brake pads, offering a blend of durability, heat dissipation, and braking performance. These materials are characterized by their composite structure, which typically includes a mixture of metallic fibers, such as steel wool or iron, combined with other ingredients like friction modifiers, fillers, and binders. The metallic fibers provide the necessary strength and thermal conductivity, allowing the brake pad to effectively absorb and dissipate heat generated during braking. This is particularly important for high-performance applications where repeated braking can lead to significant temperature increases. The inclusion of metallic fibers also enhances the frictional properties of the brake pad. Unlike organic or ceramic materials, semi-metallic brake pads maintain their frictional coefficient over a wide range of temperatures, ensuring consistent braking performance regardless of the operating conditions. This makes them ideal for heavy-duty vehicles, such as trucks and buses, as well as for vehicles that are frequently driven in demanding environments. However, semi-metallic brake pads are not without their drawbacks. They tend to be noisier and produce more brake dust compared to other types of brake pads. Additionally, they can be harsher on brake rotors, potentially leading to increased wear over time. Despite these limitations, their robustness and reliability make them a popular choice for many automotive applications. In terms of manufacturing, semi-metallic brake pads undergo a rigorous process to ensure they meet stringent safety and performance standards. The raw materials are carefully selected and mixed in specific proportions before being molded into the desired shape. The mixture is then subjected to high-pressure molding and curing processes to achieve the required density and hardness. Overall, semi-metallic materials play a vital role in the construction of brake pads, offering a balance between durability, heat management, and braking efficiency. Their widespread use in various automotive sectors underscores their importance in ensuring safe and reliable braking performance under diverse driving conditions. As technology continues to evolve, advancements in semi-metallic materials are expected to further enhance their performance characteristics, making them an even more integral part of modern braking systems.

Ceramic Materials

Ceramic materials play a crucial role in the composition of modern brake pads, offering a blend of performance, durability, and environmental benefits. Unlike traditional semi-metallic brake pads, which often contain abrasive materials like steel wool and metal fibers, ceramic brake pads are made from a mixture of ceramic fibers, other non-metallic fibers, and bonding agents. This unique composition significantly reduces the noise and vibration associated with braking, making them a preferred choice for many vehicle owners. The primary advantage of ceramic brake pads lies in their ability to provide consistent braking performance across a wide range of temperatures. Ceramic fibers, typically derived from silicon carbide or alumina, are highly resistant to heat and wear, ensuring that the brake pads maintain their effectiveness even under extreme conditions. This thermal stability also contributes to longer pad life and reduced brake dust, which is beneficial for both the environment and vehicle maintenance. Another key benefit of ceramic brake pads is their gentler interaction with the brake rotor. Unlike semi-metallic pads that can be harsh on the rotor surface, ceramic pads are designed to be less abrasive, thereby extending the lifespan of the rotor and reducing the need for frequent replacements. This characteristic makes them particularly suitable for vehicles that are driven in urban environments where frequent stops are common. In addition to their technical advantages, ceramic brake pads are also known for their eco-friendly profile. They produce fewer emissions and less particulate matter compared to their semi-metallic counterparts, aligning well with contemporary environmental standards. The reduced dust generated by ceramic pads also means less contamination of air and waterways, contributing to a cleaner environment. From a manufacturing perspective, the production of ceramic brake pads involves a sophisticated process that ensures high-quality standards. The ceramic fibers are carefully mixed with other materials such as Kevlar and rubber, then bonded together using advanced resins. This meticulous process ensures that each pad meets stringent performance criteria, including consistent friction levels and minimal fade under heavy braking conditions. In summary, ceramic materials in brake pads offer a compelling combination of performance, durability, and environmental sustainability. Their ability to provide smooth, quiet braking while extending the life of both the pads and rotors makes them an attractive option for vehicle manufacturers and consumers alike. As automotive technology continues to evolve, the role of ceramic materials in brake pad design is likely to remain significant, driving innovation towards safer, more efficient, and environmentally conscious braking solutions.

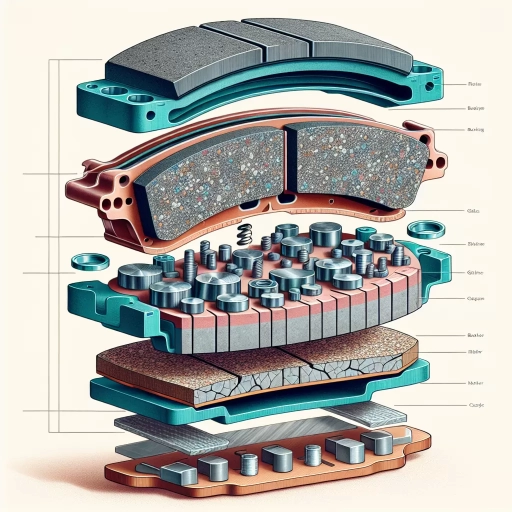

Manufacturing Process of Brake Pads

The manufacturing process of brake pads is a complex and highly specialized procedure that involves several critical stages to ensure the production of high-quality, reliable components. At the heart of this process are three key steps: Mixing and Blending, Pressing and Shaping, and Heat Treatment and Testing. Each stage plays a vital role in transforming raw materials into functional brake pads that meet stringent safety and performance standards. The journey begins with the meticulous Mixing and Blending of various materials, including friction modifiers, fillers, and binders, to create a uniform mixture that will provide the necessary frictional properties. This initial step sets the foundation for the entire manufacturing process, as it directly influences the final product's performance and durability. By understanding these interconnected stages, manufacturers can optimize their processes to produce brake pads that are both effective and safe. Let's delve into the first crucial step: Mixing and Blending.

Mixing and Blending

In the manufacturing process of brake pads, the critical step of mixing and blending is where the raw materials are meticulously combined to achieve the desired properties. This phase is pivotal as it sets the foundation for the final product's performance, durability, and safety. The process begins with the selection of a diverse array of ingredients, including friction modifiers, fillers, binders, and abrasives. Friction modifiers such as graphite or antimony trisulfide enhance the braking performance by maintaining consistent friction levels across various temperatures. Fillers like silica or calcium carbonate add bulk and help in maintaining the pad's shape while reducing costs. Binders, typically phenolic resins, hold the mixture together, ensuring structural integrity. Abrasives like alumina or silicon carbide contribute to the pad's wear characteristics and braking efficiency. Once these components are identified and measured according to precise formulations, they are introduced into a large mixing chamber. Here, they undergo a rigorous blending process to ensure uniform distribution. This is often achieved through mechanical mixing using high-speed mixers or tumblers that agitate the mixture until it reaches a homogeneous state. The blending process must be carefully controlled to avoid over-mixing, which can lead to degradation of certain materials, or under-mixing, resulting in inconsistent properties across the batch. The mixed blend is then subjected to quality control checks to verify its composition and consistency. This may involve laboratory tests such as spectroscopy or thermal analysis to ensure that the material meets the specified standards. After passing these checks, the blend is ready for the next stage of manufacturing, where it will be pressed into the desired shape using hydraulic presses or other forming techniques. The precision and thoroughness of the mixing and blending step are crucial because they directly impact the performance and reliability of the brake pads. For instance, an imbalance in friction modifiers could lead to inconsistent braking performance, while inadequate binder distribution might result in pad disintegration under heat stress. Therefore, manufacturers invest significant time and resources into optimizing this process, often leveraging advanced technologies such as computer-aided design and simulation tools to refine their formulations and mixing protocols. In summary, the mixing and blending phase in brake pad manufacturing is a complex yet essential step that requires meticulous attention to detail. By carefully selecting and combining raw materials and ensuring their uniform distribution, manufacturers can produce brake pads that meet stringent safety and performance standards, ultimately contributing to safer and more reliable vehicular operation. This critical process underscores the importance of precision engineering in modern manufacturing, where even the smallest variations can have significant implications for product quality and user safety.

Pressing and Shaping

In the manufacturing process of brake pads, pressing and shaping are critical steps that ensure the final product meets stringent performance and safety standards. This phase follows the meticulous blending of raw materials, including frictional additives, binders, and fillers, which are mixed to achieve a uniform composition. The blended mixture is then transferred to a press where it undergoes a high-pressure compaction process. Here, hydraulic presses apply immense force—often in the range of several hundred tons per square inch—to compress the mixture into the desired shape. This pressing action not only densifies the material but also aligns the fibers and particles in a way that enhances the pad's frictional properties and durability. The shaping process is equally important as it involves precision engineering to ensure that the brake pads conform to the exact specifications required for each vehicle model. Modern manufacturing facilities employ advanced CNC machining and automated systems to achieve precise dimensions and surface finishes. These systems can produce complex geometries with high accuracy, ensuring that every brake pad fits perfectly onto the brake rotor or drum without any deviations that could compromise braking performance. During this stage, quality control measures are rigorously implemented to detect any defects or irregularities. Visual inspections, dimensional checks, and material testing are conducted to verify that the pressed and shaped brake pads meet or exceed industry standards. Additionally, some manufacturers may subject their products to further processing such as surface grinding or chamfering to improve fitment and reduce noise during operation. The combination of precise pressing and shaping techniques ensures that brake pads exhibit consistent frictional behavior under various driving conditions. This consistency is crucial for maintaining reliable braking performance, which is a cornerstone of vehicle safety. Moreover, advancements in pressing and shaping technologies have enabled manufacturers to produce brake pads with customized friction profiles tailored to specific vehicle types and driving environments. In summary, the pressing and shaping phase in brake pad manufacturing is a sophisticated process that demands high precision and adherence to quality standards. By leveraging advanced machinery and stringent quality control measures, manufacturers can produce brake pads that are not only durable but also provide optimal braking performance across diverse driving scenarios. This attention to detail underscores the importance of these steps in ensuring that brake pads are reliable components of modern vehicles' braking systems.

Heat Treatment and Testing

Heat treatment and testing are crucial steps in the manufacturing process of brake pads, ensuring these critical automotive components meet stringent safety and performance standards. Heat treatment involves subjecting the brake pad material to controlled heating and cooling processes to alter its microstructure, thereby enhancing its mechanical properties. For instance, sintering—a common heat treatment method for metallic brake pads—fuses metal powders together at high temperatures, creating a strong and durable bond. This process improves the pad's frictional characteristics, wear resistance, and thermal stability, which are essential for consistent braking performance under various driving conditions. In addition to heat treatment, rigorous testing is conducted to validate the quality and reliability of brake pads. These tests include friction testing, where the pads are subjected to different speeds and pressures to measure their stopping power and stability. Wear testing assesses how well the pads resist degradation over time, ensuring they maintain their effectiveness throughout their lifespan. Thermal testing evaluates the pad's ability to withstand high temperatures generated during braking, a critical factor in preventing brake fade. Dynamic testing, such as those performed on dynamometers, simulates real-world driving scenarios to evaluate the pads' performance under various conditions. Moreover, chemical analysis and microstructural examination are performed to ensure the material composition meets specifications. These tests help identify any defects or inconsistencies that could compromise the pad's performance or safety. The results from these comprehensive tests are used to fine-tune the manufacturing process, ensuring that every batch of brake pads produced adheres to industry standards and regulatory requirements. The integration of advanced technologies, such as computer-aided design (CAD) and finite element analysis (FEA), further enhances the heat treatment and testing processes. These tools allow manufacturers to simulate different scenarios and optimize the design of brake pads before physical prototypes are created, reducing development time and costs while improving overall product quality. In summary, heat treatment and testing are indispensable components of the brake pad manufacturing process. By combining advanced heat treatment techniques with rigorous testing protocols, manufacturers can produce brake pads that offer superior performance, durability, and safety. This meticulous approach ensures that brake pads consistently meet the high standards required for safe and reliable vehicle operation, making them a vital part of modern automotive engineering.

Performance Characteristics of Different Brake Pad Materials

When evaluating the performance characteristics of different brake pad materials, several key factors come into play. These include the friction coefficient and stopping power, noise and vibration reduction, and durability and wear resistance. Each of these aspects significantly influences the overall braking performance and safety of a vehicle. The friction coefficient, for instance, directly impacts the stopping power of the brakes, determining how quickly and effectively a vehicle can come to a halt. Noise and vibration reduction are crucial for enhancing driver comfort and reducing wear on other components. Meanwhile, durability and wear resistance ensure that brake pads maintain their performance over time without frequent replacements. Understanding these performance characteristics is essential for selecting the right brake pad material for specific driving conditions and vehicle types. By delving into these critical areas, we can better appreciate how different materials excel in various scenarios. Let's begin by examining the friction coefficient and stopping power, as these are foundational to the braking process.

Friction Coefficient and Stopping Power

The friction coefficient and stopping power of brake pads are crucial performance characteristics that significantly impact the overall braking efficiency and safety of a vehicle. The friction coefficient, a dimensionless quantity, represents the ratio of the force of friction between two surfaces to the normal force pressing them together. In the context of brake pads, it determines how effectively the pads can slow down or stop the vehicle by converting kinetic energy into heat. Different materials used in brake pad construction exhibit varying friction coefficients, influencing their stopping power. For instance, organic brake pads, made from a mixture of rubber, resin, and other organic materials, typically have a lower friction coefficient compared to semi-metallic or ceramic pads. This results in smoother braking but may compromise on stopping power, especially under heavy loads or high speeds. Semi-metallic brake pads, containing metal fibers like steel wool or iron, offer higher friction coefficients and superior stopping power due to their robustness and heat dissipation capabilities. However, they can be noisier and may cause more wear on the brake rotors. Ceramic brake pads, composed of ceramic fibers and other inorganic materials, strike a balance between friction coefficient and wear resistance. They provide a quieter operation and less rotor wear compared to semi-metallic pads while maintaining a respectable level of stopping power. Carbon-carbon brake pads, often used in high-performance vehicles and aircraft, exhibit exceptionally high friction coefficients but are expensive and require specific operating conditions to function optimally. The choice of brake pad material is thus a trade-off between several factors including noise level, rotor wear, heat dissipation, and most importantly, stopping power. Manufacturers must carefully select materials that meet the specific requirements of different driving conditions and vehicle types to ensure optimal performance and safety. For example, vehicles intended for heavy-duty use or those designed for high-speed applications may benefit from semi-metallic or carbon-carbon brake pads due to their superior stopping power, whereas passenger vehicles might prefer ceramic or organic pads for their quieter operation and lower maintenance costs. In conclusion, the friction coefficient and stopping power of brake pads are critical determinants of a vehicle's braking performance. Understanding the properties of various materials used in brake pad construction allows for informed decisions that balance safety, efficiency, and comfort. By selecting the appropriate brake pad material based on the intended use and operating conditions of the vehicle, manufacturers can enhance overall braking performance and contribute to safer driving experiences.

Noise and Vibration Reduction

Noise and vibration reduction are critical performance characteristics when evaluating different brake pad materials. The primary goal of brake pads is to provide effective braking while minimizing unwanted sounds and vibrations that can compromise both safety and comfort. Various materials are used in the manufacture of brake pads, each with its own strengths and weaknesses in terms of noise and vibration reduction. **Organic Brake Pads**, for instance, are known for their softer composition, which often results in quieter operation compared to other types. These pads typically contain a mix of natural fibers like rubber, Kevlar, and other organic materials. The softer nature of these pads helps in absorbing vibrations and reducing noise levels during braking. However, they may wear out faster and generate more brake dust. **Semi-Metallic Brake Pads** offer a balance between noise reduction and durability. These pads contain a higher percentage of metal fibers such as steel wool or iron, which provide better heat dissipation and longer lifespan compared to organic pads. While they can be noisier than organic pads due to the metal content, advancements in manufacturing have led to the development of semi-metallic pads with improved noise-reducing properties. **Ceramic Brake Pads** are renowned for their superior noise and vibration reduction capabilities. Made from a combination of ceramic fibers and other materials, these pads are designed to be quieter and produce less dust than both organic and semi-metallic pads. The ceramic fibers help in dissipating heat efficiently while minimizing the generation of noise-causing vibrations. This makes ceramic brake pads an excellent choice for drivers who prioritize a smooth and quiet braking experience. **Low-Metallic Brake Pads** fall somewhere between semi-metallic and organic pads in terms of their composition and performance. They contain a lower percentage of metal fibers compared to semi-metallic pads but more than organic pads. This blend allows for a moderate level of noise reduction while maintaining a reasonable lifespan and braking performance. In addition to the material composition, other factors such as pad shape, surface texture, and the presence of noise-reducing features like chamfers or slots can significantly impact the overall noise and vibration levels during braking. Manufacturers often employ these design elements to enhance the performance of their brake pads across different materials. In conclusion, the choice of brake pad material plays a crucial role in determining the level of noise and vibration experienced during braking. By understanding the unique characteristics of each type—organic, semi-metallic, ceramic, and low-metallic—drivers can make informed decisions that align with their priorities for safety, comfort, and overall driving experience. Whether it's the quiet operation of ceramic pads or the durability of semi-metallic pads, selecting the right material can significantly enhance the performance and comfort of a vehicle's braking system.

Durability and Wear Resistance

Durability and wear resistance are paramount performance characteristics when evaluating the effectiveness of brake pads. These attributes directly influence the lifespan and reliability of brake pads, ensuring consistent braking performance over time. Different materials used in brake pad construction exhibit varying levels of durability and wear resistance, each with its own set of advantages and limitations. **Organic Brake Pads**, for instance, are made from a mixture of natural fibers, resins, and fillers. While they offer good noise reduction and initial braking performance, they tend to wear out faster compared to other materials. This is because organic compounds are more prone to degradation under heat and friction, leading to a shorter service life. In contrast, **Semi-Metallic Brake Pads** incorporate metallic fibers such as steel wool or iron, which significantly enhance their durability and wear resistance. These pads are more robust and can withstand higher temperatures without compromising their braking efficiency. However, they may produce more noise and can be harsher on brake rotors due to their abrasive nature. **Ceramic Brake Pads** represent a modern advancement in brake pad technology, combining the benefits of both organic and semi-metallic pads. Made from a blend of ceramic fibers, resins, and other fillers, these pads offer excellent durability and wear resistance while maintaining a quieter operation. Ceramic pads are less abrasive on brake rotors and provide consistent braking performance across various driving conditions. **Low-Metallic Brake Pads** strike a balance between semi-metallic and organic pads by using a lower percentage of metallic fibers. This composition aims to mitigate the noise and rotor wear associated with semi-metallic pads while still offering improved durability compared to organic pads. They are a popular choice for many vehicle manufacturers due to their balanced performance characteristics. **Carbon-Carbon Brake Pads**, often used in high-performance applications such as racing, exhibit exceptional durability and wear resistance. These pads are made from carbon fibers bonded with a carbon matrix, providing superior heat dissipation and resistance to wear under extreme conditions. However, they are typically more expensive and may require specialized rotors to function optimally. In conclusion, the durability and wear resistance of brake pads are critical factors that influence their overall performance and lifespan. The choice of material depends on the specific requirements of the vehicle, driving conditions, and personal preferences. Understanding the unique characteristics of each material type allows for informed decisions that ensure optimal braking performance and safety. Whether it's the quiet operation of ceramic pads or the robustness of semi-metallic pads, selecting the right brake pad material is essential for maintaining reliable braking capabilities over time.